A shockproof, heat-resistant temperature sensor

A heat-resistant temperature and sensor technology, used in heat-resistant temperature sensors and shock-proof fields, can solve problems such as pull-off, temperature sensor failure, thermal conductive adhesive deformation, etc., to avoid loosening and failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

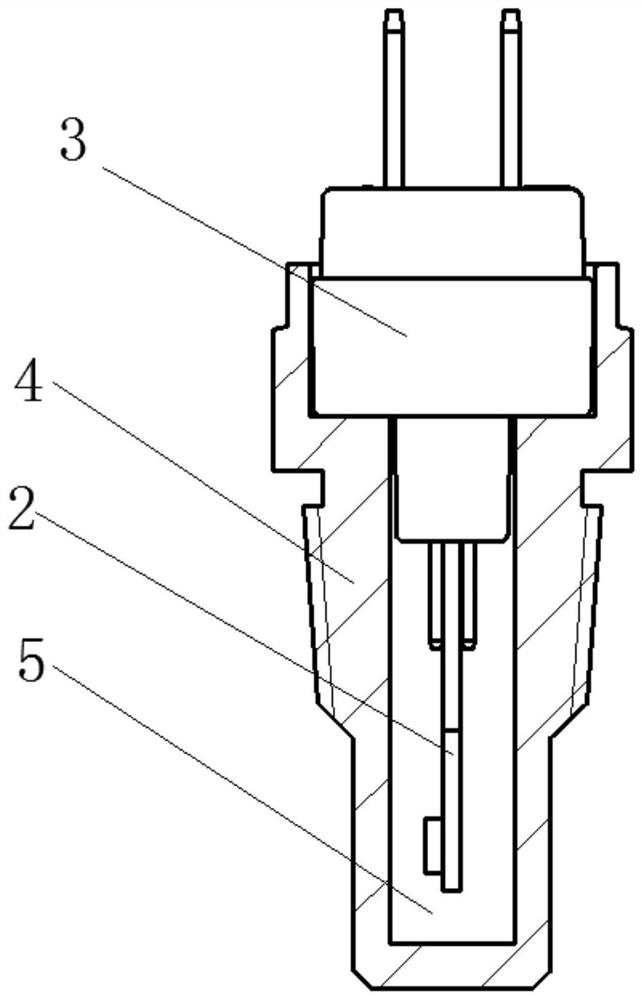

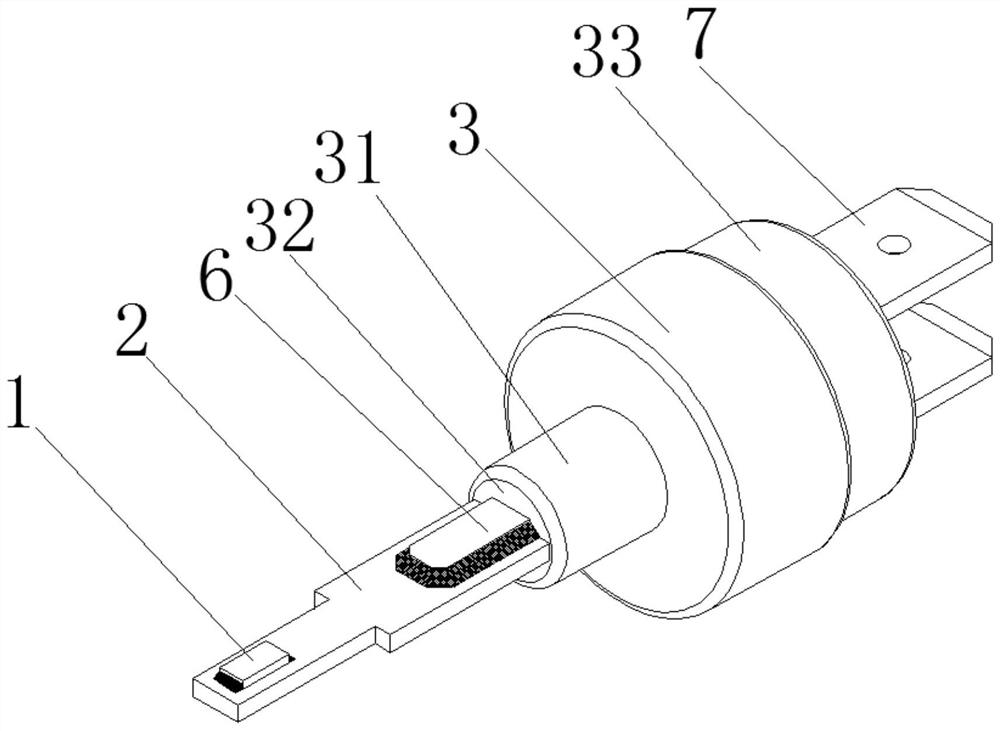

[0018] A shockproof and heat-resistant temperature sensor, comprising a detection element 1, a circuit board 2, a mounting base 3, a heat conduction cover 4, and an insertion piece 7; the two ends of the mounting base 3 are installation ends and detection ends respectively, and the detection element 1 is installed on the detection end of the mounting base 3, the insert piece 7 is installed on the mounting end of the mounting base 3, a heat conduction cover 4 is also provided on the detection end of the mounting base 3, and the detection element 1 is installed through the circuit board 2 On mount 3. By changing the connection mode of the sensor to patch connection, the loosening of the connection point is avoided, and it also prevents the heat-conducting glue from deforming after being heated when the sensor is working during the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com