Connector

一种连接器、同轴电缆的技术,应用在连接、导电连接、两部件连接装置等方向,能够解决增大紧固环4和被折叠的屏蔽部件8摩擦力、连接器1大型化、紧固环易脱落等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

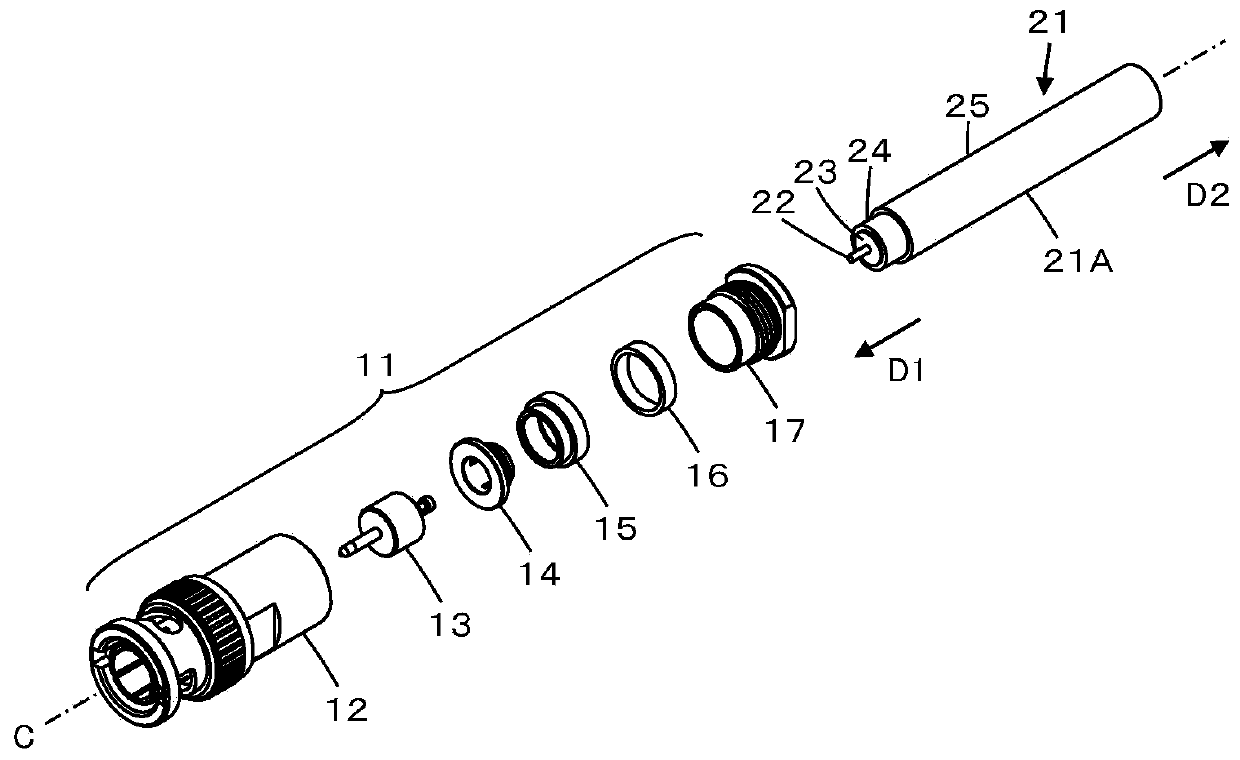

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

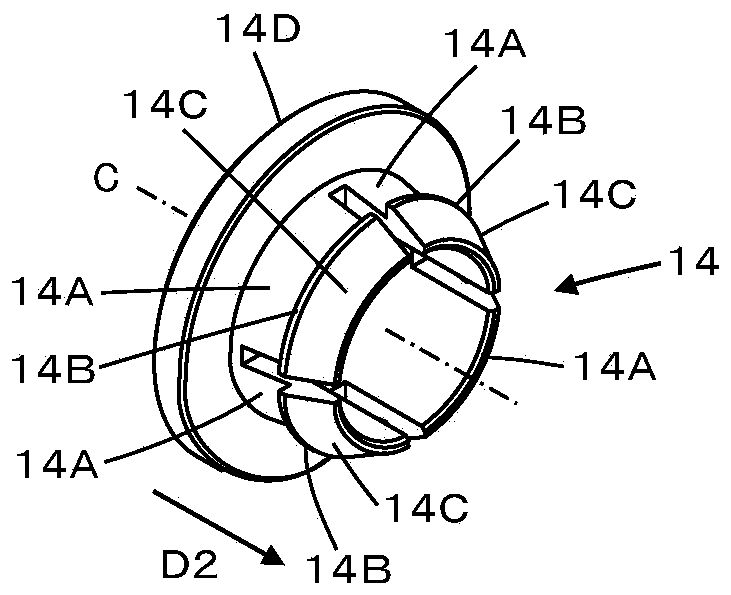

[0033] figure 1 It is an assembly drawing of the connector 11 which concerns on embodiment. The connector 11 is installed on the front end 21A of the coaxial cable 21, and has the following structure, that is, along the central axis C, the central contact assembly 13, the inner sleeve 14, and the outer sleeve are sequentially assembled in the connector body 12. 15. Washer 16 and fastening nut 17.

[0034] Furthermore, the coaxial cable 21 has a central conductor 22 , an insulator 23 covering the outer periphery of the central conductor 22 , a shield member 24 covering the outer periphery of the insulator 23 , and a sleeve 25 covering the outer periphery of the shield member 24 .

[0035] At this time, for convenience, the direction along the coaxial cable 21 and toward the front end 21A of the coaxial cable 21 is referred to as a first direction D1, and the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com