CCD label detector

A label detection and detection machine technology, which is applied in the direction of optical testing flaws/defects, winding strips, thin material processing, etc. The belt transmission path is simple, which is conducive to precise control and avoids the effect of falling off the label

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

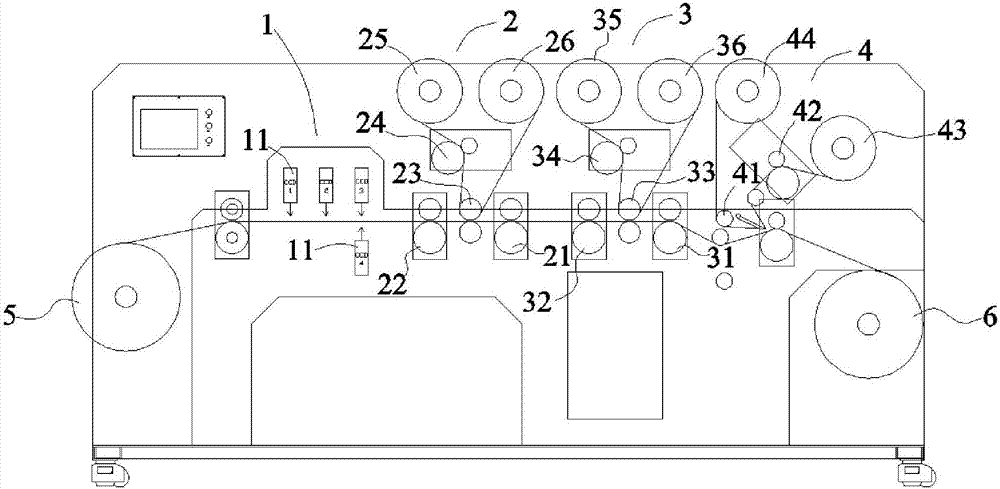

[0025] Such as figure 1 As shown, the CCD label detection machine of the present invention includes: a CCD label detection device 1 , a primary label removal device 2 , a secondary label removal device 3 and a label replenishment device 4 arranged in sequence.

[0026] The CCD label detection device 1 includes several CCD detection units 11 for detecting labels, and the several CCD detection units 11 distinguish primary unqualified labels and secondary unqualified labels on the tape. Among them, the first-level unqualified label ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com