Terminal correctional storage box installation equipment

A technology for installing equipment and storage tanks, which is applied in the field of installation equipment for finishing storage tanks, can solve problems such as complicated installation paths and difficult installation and transportation, and achieve the effect of ensuring installation quality and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] In order to meet the explosion-proof requirements of the production site and ensure the safety of products and personnel, the present invention adopts a full-process mechanical method to extract and install the storage tank.

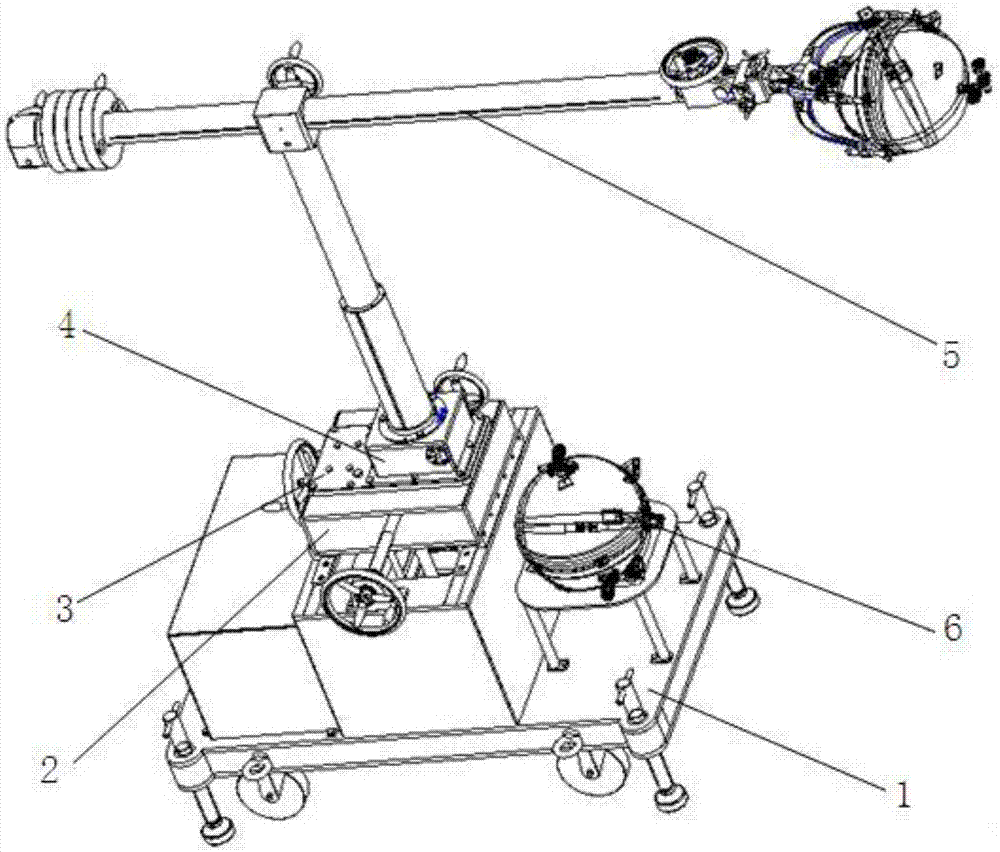

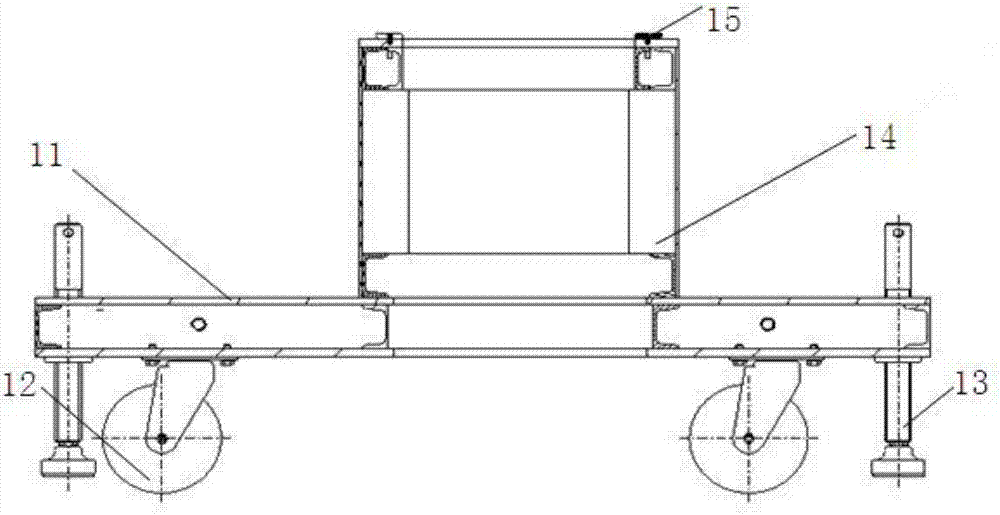

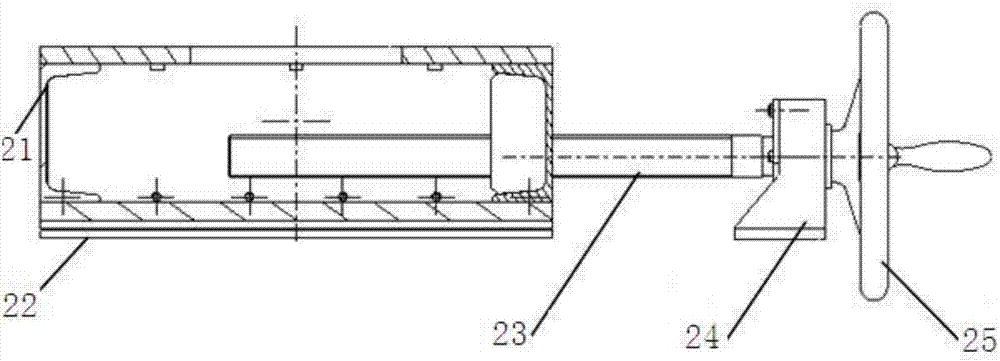

[0047] The finishing tank installation equipment of this embodiment includes a base 1, a translation mechanism 2, a lifting mechanism 3, a rotation mechanism 4 and an installation arm 5, a total of five modules, with a total of eight degrees of freedom, all of which are mechanically adjusted to complete each action;

[0048] figure 1 It is the overall structure diagram of the present invention: base 1, translation mechanism 2, lifting mechanism 3, rotation mechanism 4 and installation arm 5, five functional modules are connected and assembled sequentially from bottom to top, according to the storage, 6 assembly directions, figure 1 The direction in which the middle mounting arm 5 connects to the storage tank 6 is the front, and the following will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com