Roller guiderail die movement device

A roller guide rail and mold moving technology, applied in the field of molding sand molding production, can solve the problems of affecting production efficiency and low efficiency of manual operation, and achieve the effects of simple structure, convenient transportation and positioning, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

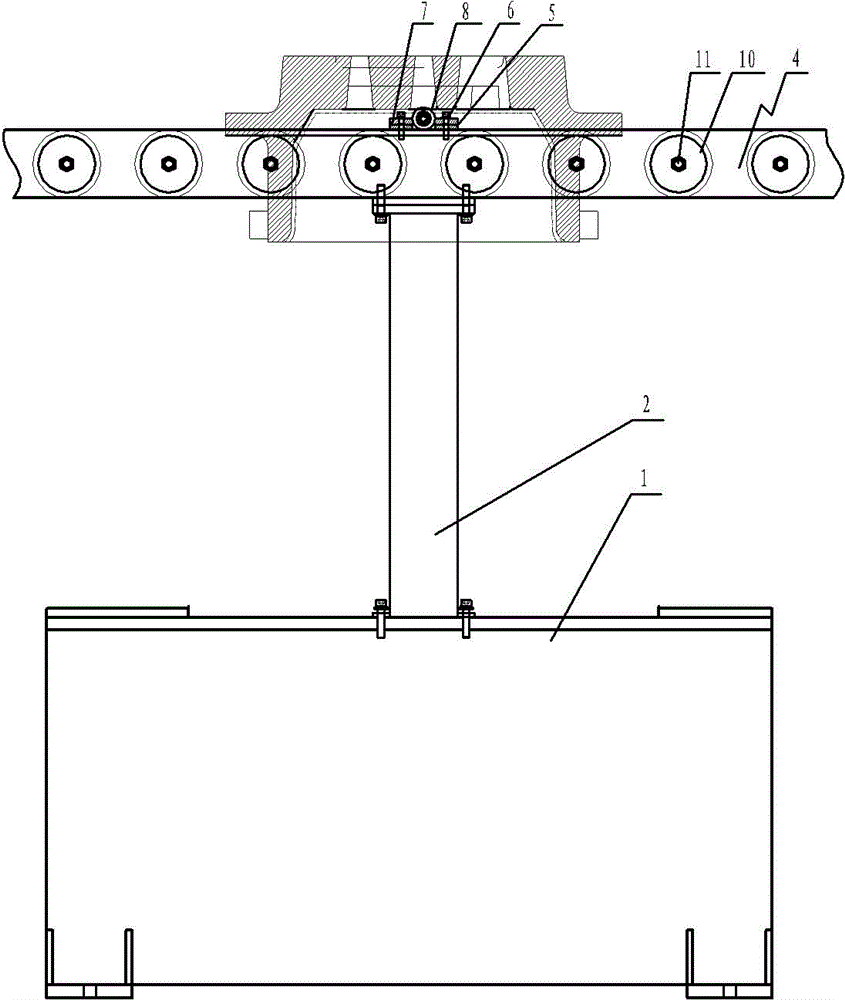

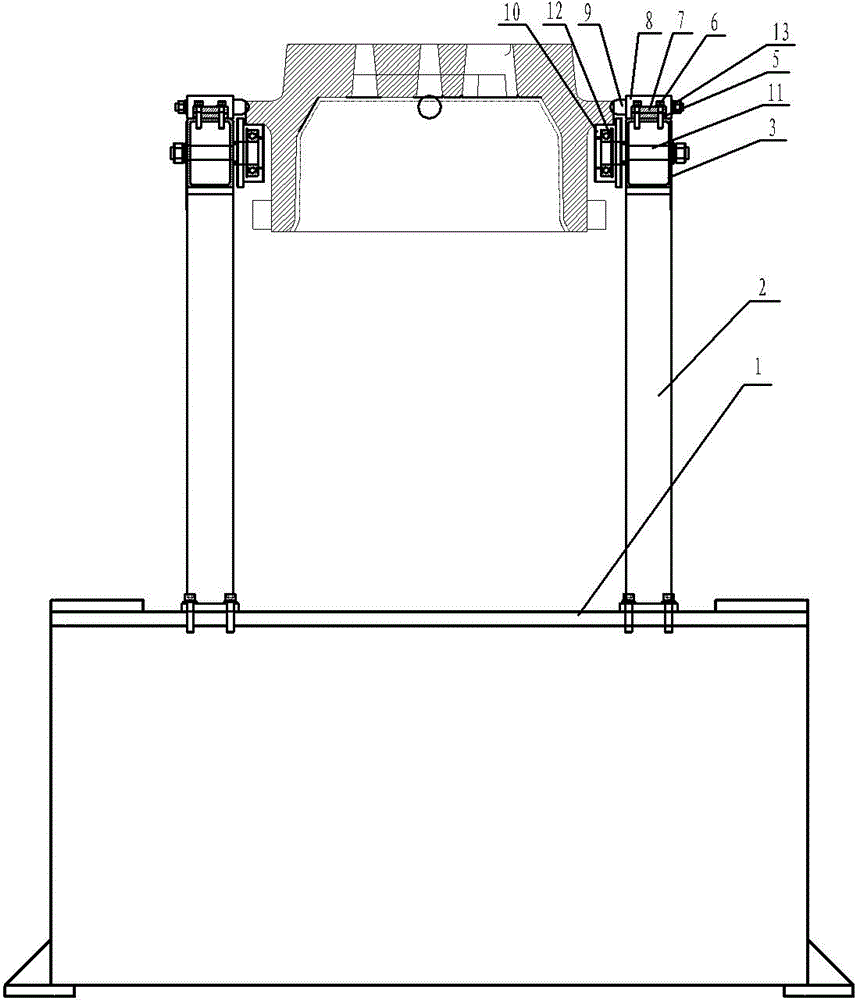

[0010] See figure 1 , figure 2 As shown, a roller guide rail mold moving device includes a base 1, brackets 2 are respectively arranged on both sides of the base 1, a support seat 3 is arranged on the bracket 2, a roller guide rail 4 is arranged on the inner side of the support seat 3, and a positioning seat 5 is arranged on the support seat 3 , the upper end of the positioning seat 5 is connected to the positioning plate 7 through the adjusting bolt 6, the positioning block 8 is fixedly connected to the positioning plate 7, and the adjustable positioning rod 9 is arranged on the inside of the positioning block 8; the roller guide rail 4 includes a plurality of rollers 10 arranged side by side. 10 is connected with supporting seat 3 by rotating shaft 11, and bearing 12 is set between roller 10 and rotating shaft 11; External thread is set on positioning rod 9, and positioning block 8 has threaded hole, and positioning rod 9 is threadedly connected with the threaded hole of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com