Sleeve vent folding mechanism with replaceable template

A folding mechanism and template technology, applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the problems of high cost of making clothes, easy to make mistakes, complicated operation process, etc., and achieve stable processing quality, strong versatility, and operation. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

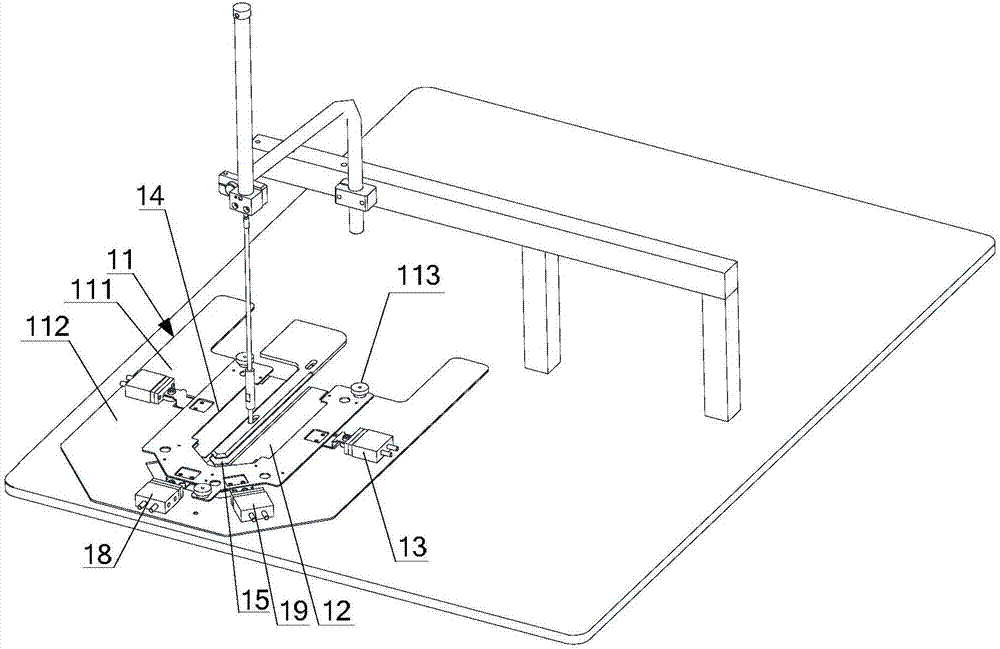

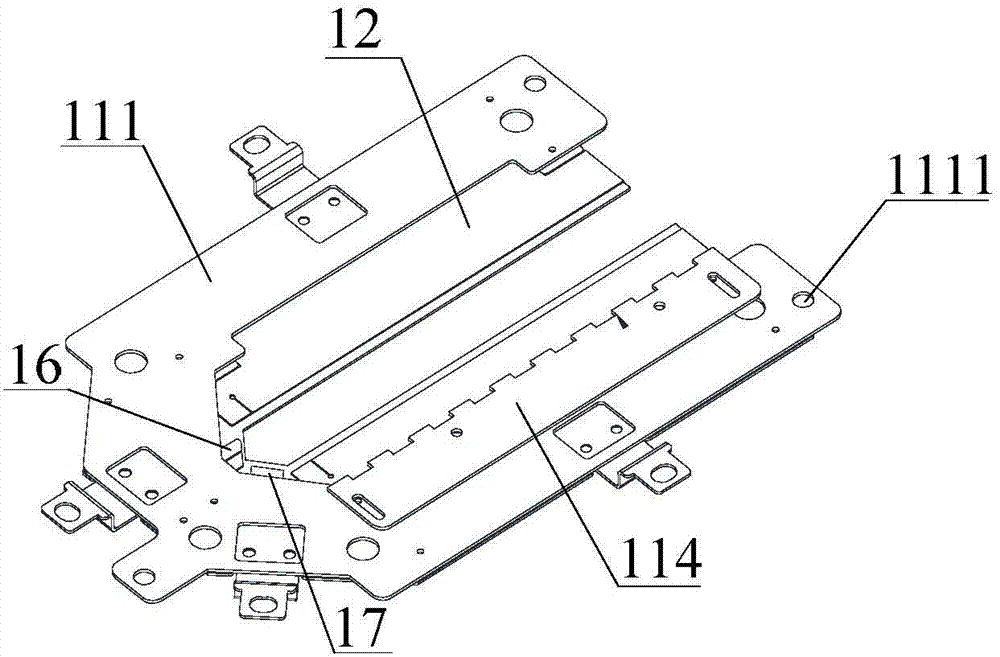

[0014] Below according to the attached Figure 1 ~ Figure 2 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0015] see figure 1 with figure 2 , an interchangeable sleeve yoke folding mechanism according to an embodiment of the present invention, comprising a template assembly 11, two first insertion pieces 12 and two first transmission assemblies 13; the template assembly 11 extends along a first direction and 11 A processing groove 14 with an opening at the first end, the middle part of the processing groove 14 is recessed to form a fixed groove 15 extending along the first direction; the template assembly 11 forms an installation space, and the first insertion piece 12 is aligned with the first direction Parallel and reciprocatingly moved along a second direction through the first transmission assembly 13, they are opposite to the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com