Shredding method of waste paper for papermaking

A technology of waste paper and shredded paper, which is applied in the field of papermaking, can solve the problems of uneven shredded paper and easy blockage of the output, and achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail through specific embodiments below.

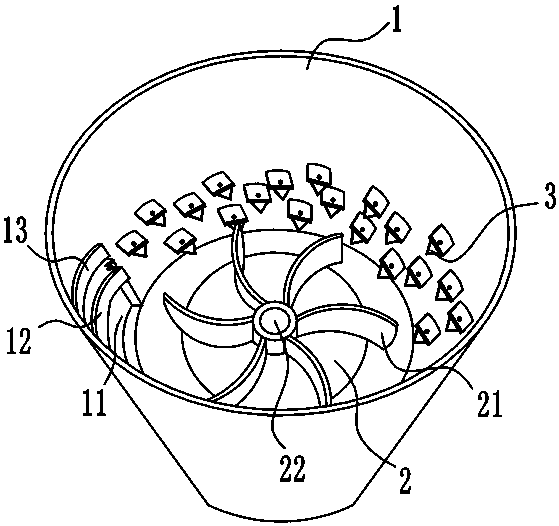

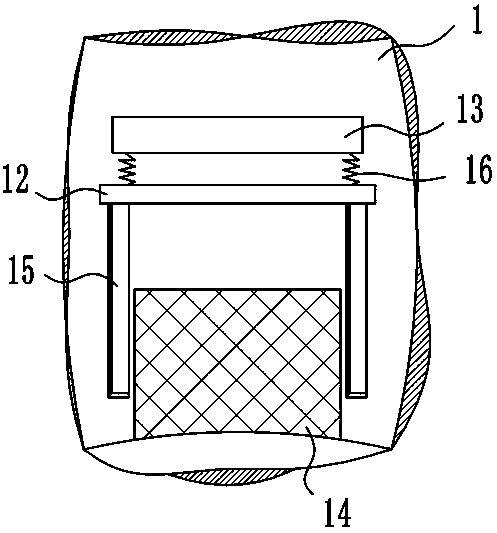

[0032] The reference signs in the accompanying drawings of the specification include: barrel 1, driving impeller 2, cutter 3, switch cover 4, mounting seat 5, discharge port 11, push block 12, spring seat 13, filter screen 14, guide groove 15 , Extension spring 16, driving wheel sheet 21, impeller shaft 22, copper sheet 41, I-shaped post 51, retaining sheet 52, and sheet 53.

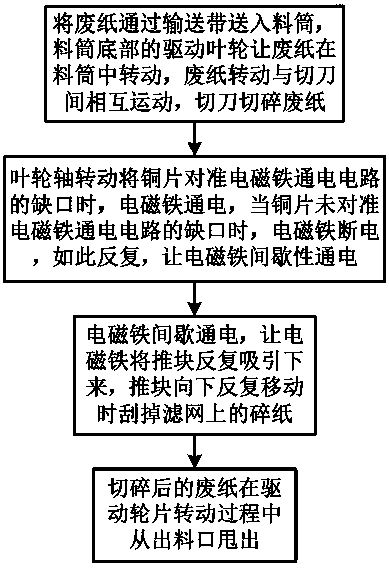

[0033] Shredding methods of paper waste paper, including the following, such as figure 1 Shown:

[0034] S1, before adding waste paper into the barrel, let the driving motor drive the impeller to rotate, and then send the recovered waste paper into the barrel through the conveyor belt. After the waste paper enters the barrel, the driving wheel on the driving impeller drives The waste paper rotates, and when the waste paper rotates, it moves relative to the cutter on the inner wall of the barrel, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com