Low-temperature granulator and thin film plastic recovery system

A granulator and low-temperature technology, which is applied in the field of low-temperature granulator and film plastic recycling system, can solve the problems of increasing unsafety, potential hidden dangers, increasing the volume of low-temperature granulator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with each accompanying drawing, the present invention is described in detail.

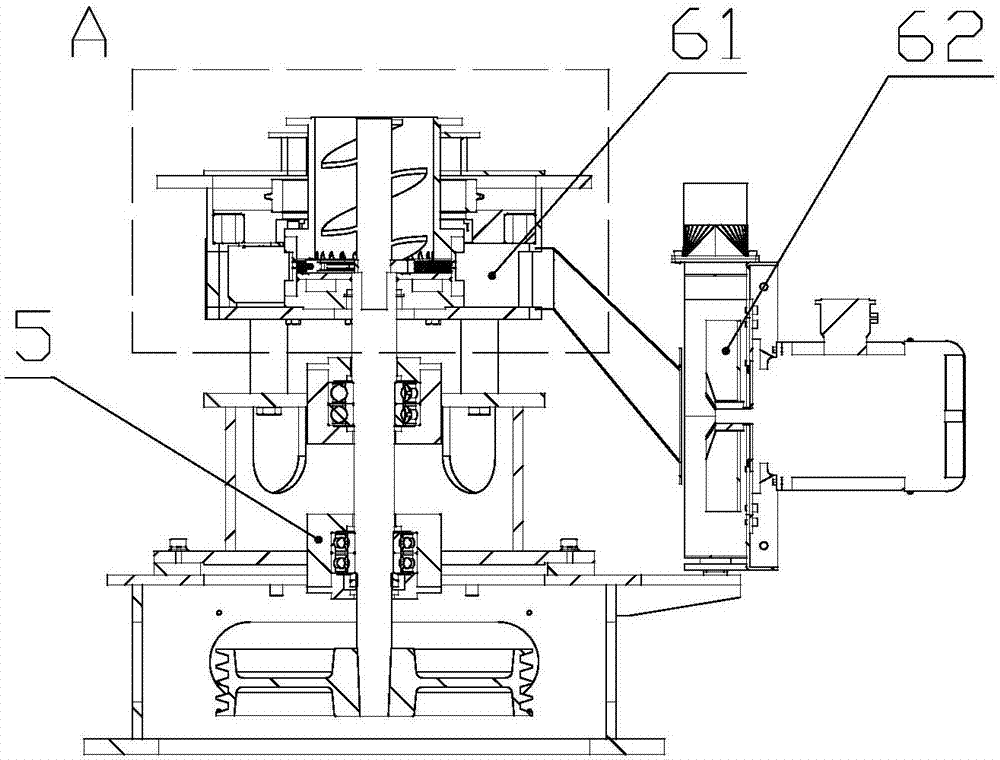

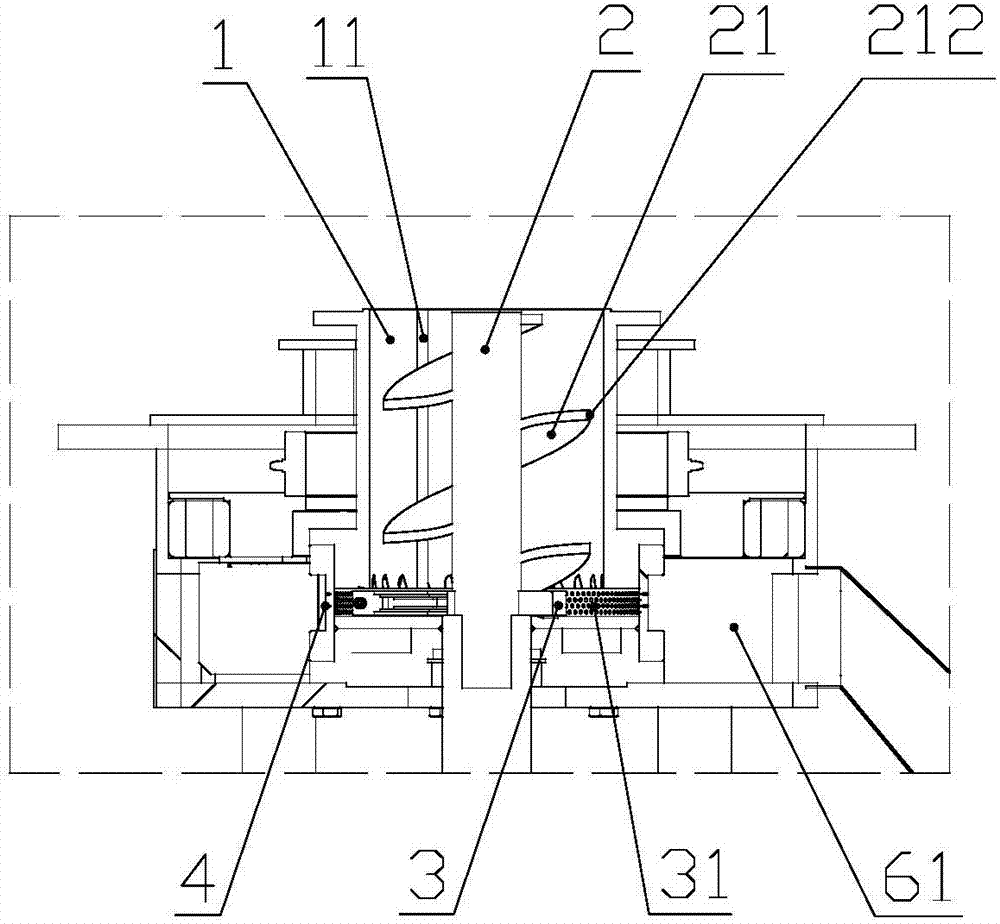

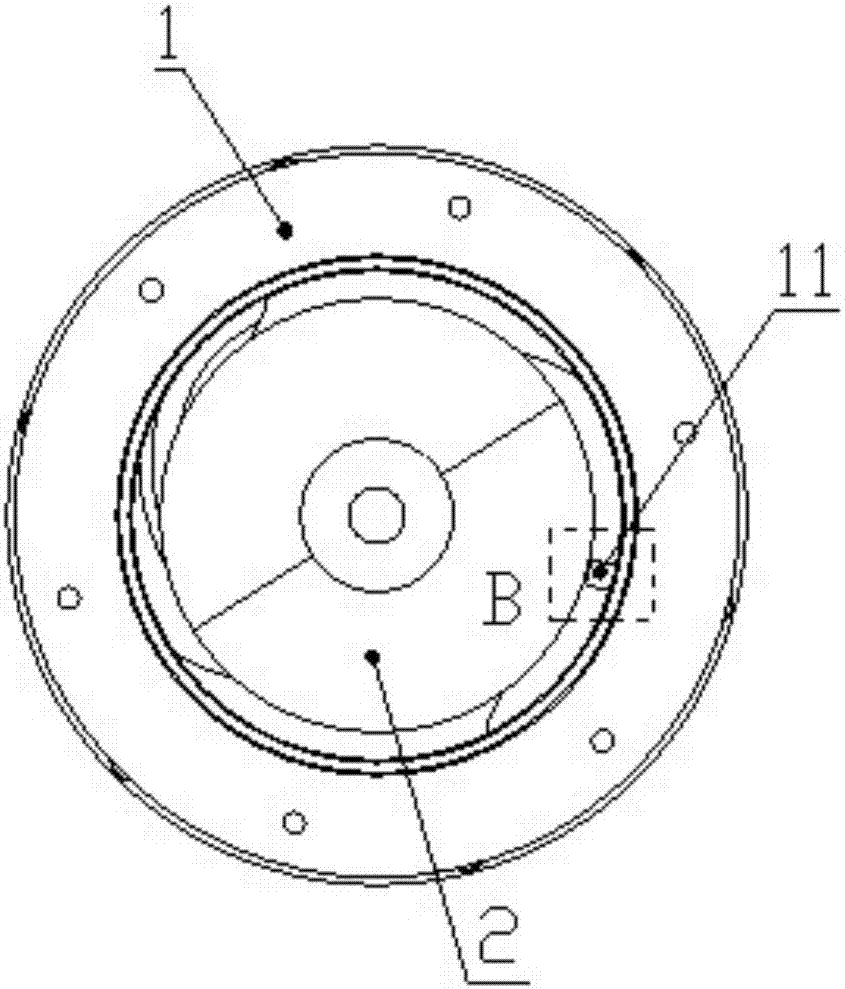

[0030] Please refer to Figure 1-4 , the embodiment of the present invention provides a low-temperature granulator, comprising: a cylinder body 1, an extrusion S screw 2, an extrusion disk 3, a pelletizing blade knife 4 and a first driving device 55; one end of the cylinder body 1 is provided with a feed The inner wall of the cylinder is provided with a slant 11; the extrusion S screw 2 of the low-temperature granulator is arranged in the cylinder, and the axis of the extrusion S screw 2 coincides with the axis of the cylinder; the cutting blade knife 21 of the extrusion S screw 2 The edge 211 is provided with corners 212; the extruding disc 3 is arranged at the bottom of the cylinder, and the extruding disc 3 is provided with an extruding screen 31; It is connected with the extruding S screw 2 and the cutting blade knife 4 in transmission.

[0031] The waste plastics ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com