Steam trap universal connector

A technology of universal connectors and universal joints, which is applied to steam traps, pipes/pipe joints/fittings, branch pipelines, etc., can solve problems such as increased manufacturing costs, rupture, and water hammer pipes, and reduce manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

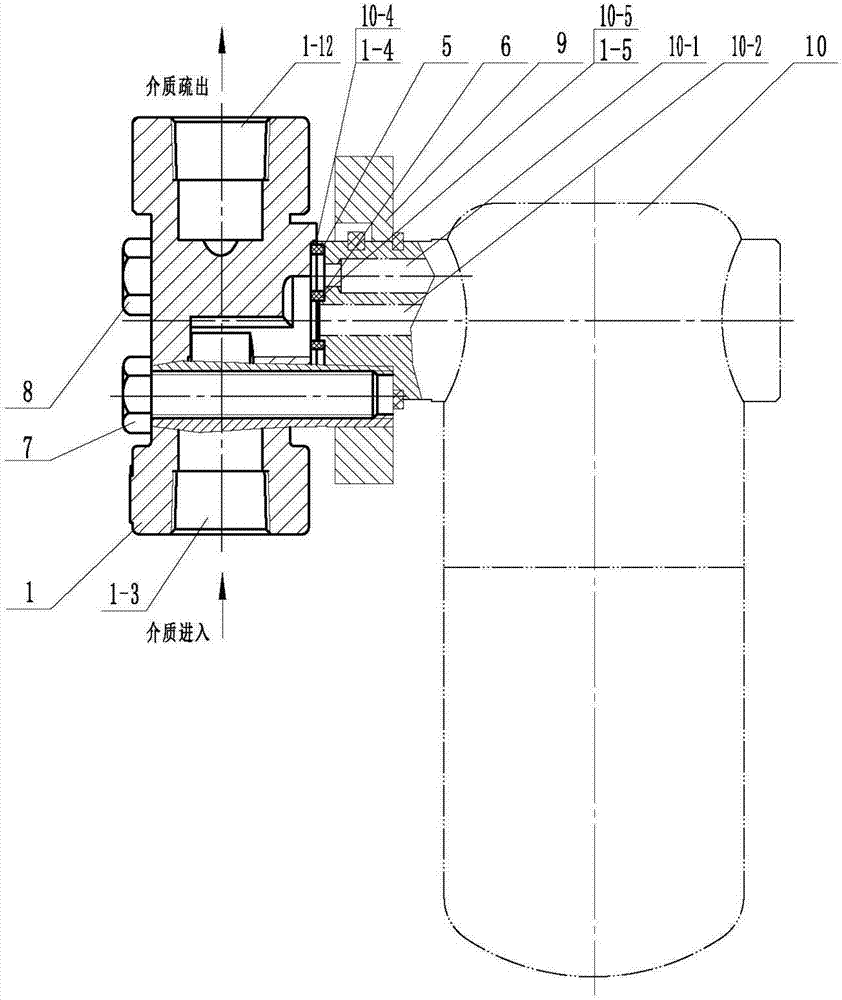

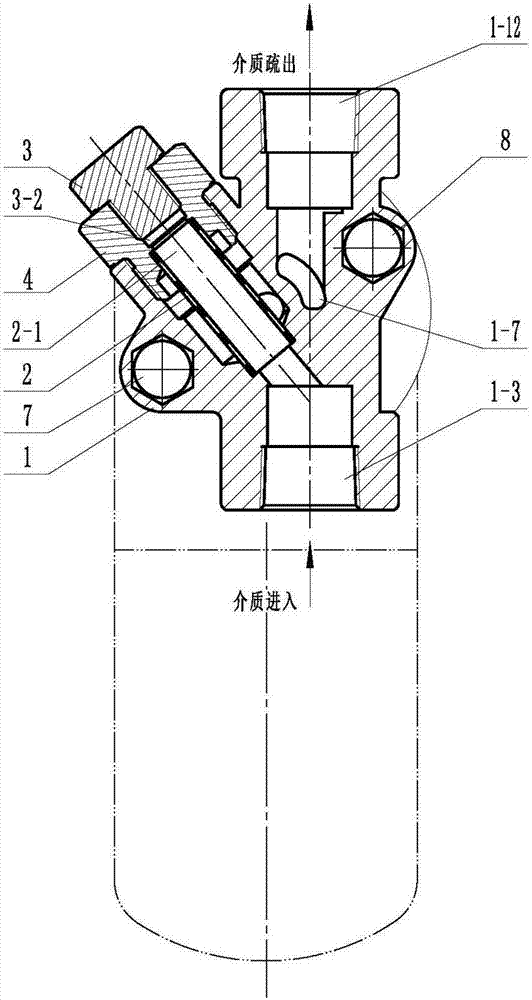

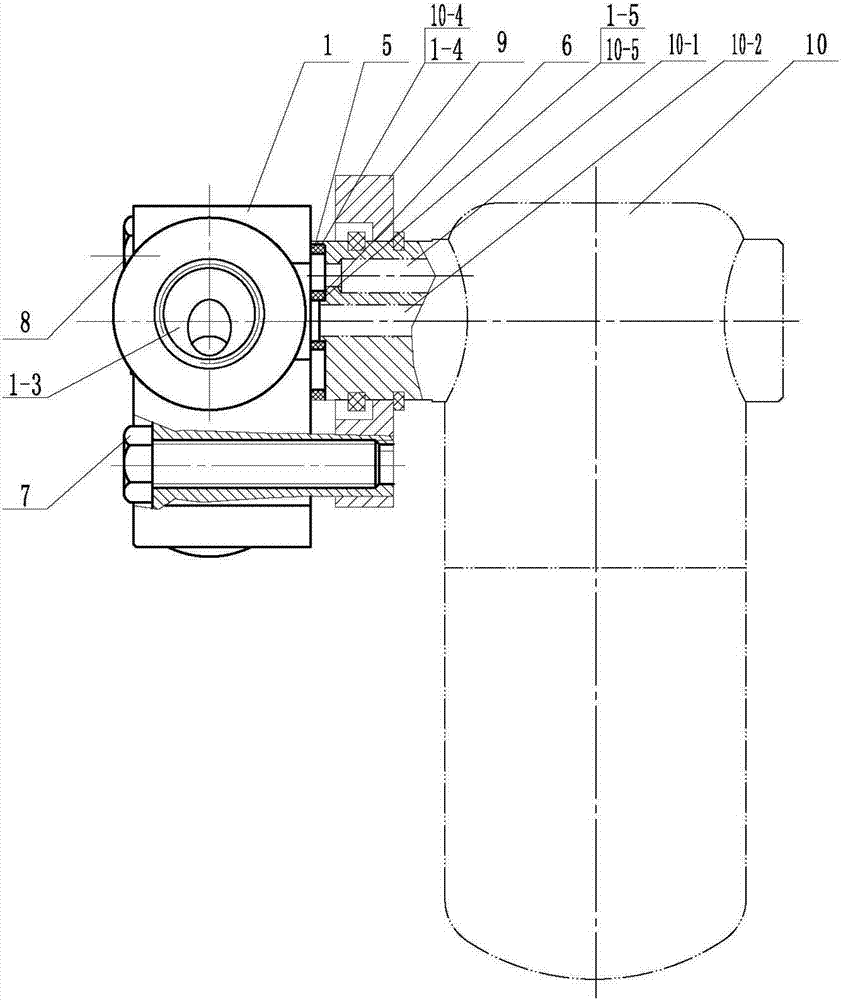

[0027] exist figure 1 , 2 , 7, 8, 9, 10, 11, 12, 13, 14, and 15: a universal connector for a drain valve of the present invention is a horizontal connection. The housing 1 is Y-shaped, and the two ends of the housing 1 are respectively provided with a medium entering cavity 1-3, a medium evacuating cavity 1-12, and the upper part of the medium entering cavity 1-3 and the medium evacuating cavity 1-12 Both taper threads are used. The casing 1 is provided with a cavity 1-1, the cavity 1-1 is stepped, one end of the cavity 1-1 communicates with the medium entering the cavity 1-3, and the other end is provided with an internal thread 1-14, The medium evacuation cavity 1-12 communicates with the casing outlet flow channel 1-7. A filter screen 2 is installed in the cavity 1-1, one end of the filter screen 2 is pushed against the end face 1-13 in the cavity 1-1, and the other end penetrates into the cavity 4-4 of the large bolt 4 to filter The net 2 is tightly fixed on the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com