Intelligent remote control hot-line operation rod

A live operation, intelligent remote control technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of long distance, looseness of the insulated bucket arm, weak connection between the insulated operating rod and the live wire clip, etc., to increase operability and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

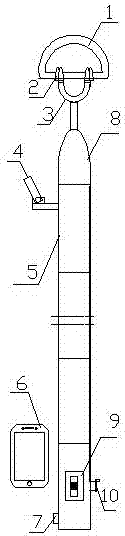

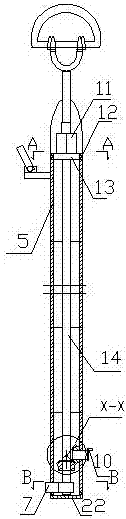

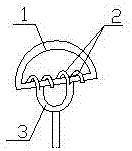

[0015] like figure 1 , 2 , 3, 4, 5, and 6, the intelligent remote control live operating rod includes several movably connected insulating rods 5, insulating operating hooks, electric rotating mechanisms, and manual rotating mechanisms, and a camera is provided on the insulating rods. 4. The camera is wirelessly connected to the camera monitor 6 (the angle of the camera can be adjusted through WIFI connection and the pan / tilt), the insulating operation hook includes a Y-ring 3, and the two ends of the top of the Y-ring are symmetrically provided with openings located opposite to each other. Hook bodies 2 staggered from each other (eg image 3 The electric rotating mechanism includes a protective cover 8 arranged on the top ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com