Aluminium-magnesium alloy cable bridge

A technology of aluminum-magnesium alloy and cable tray, which is applied in the direction of electrical components, can solve the problems of cable damage, high installation cost, and a large number of screws, and achieve the effects of strengthening structural stability, strengthening corrosion resistance, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

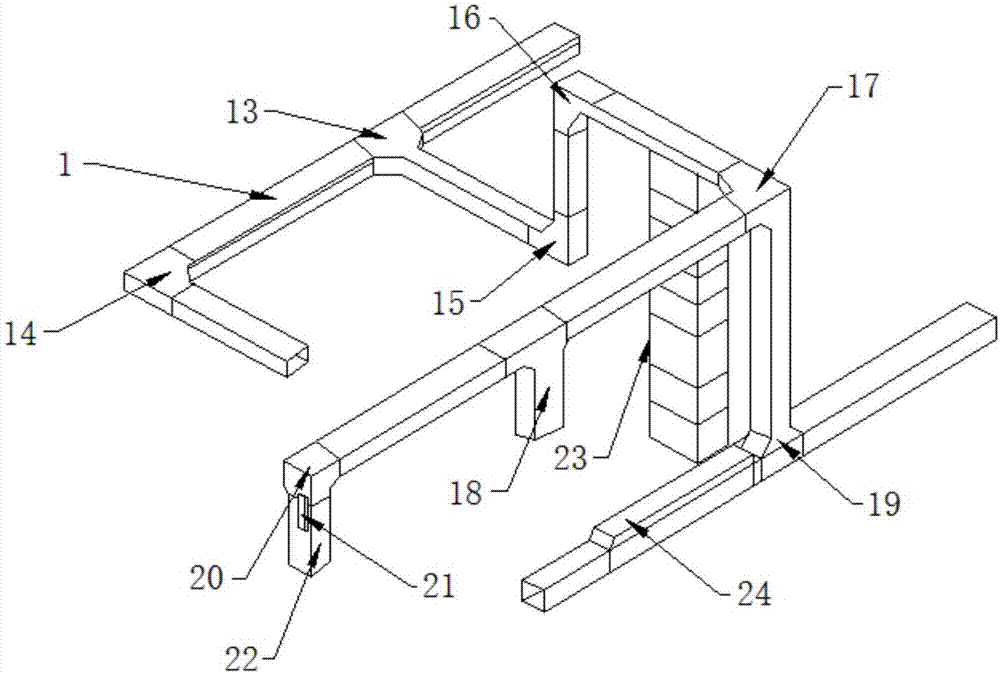

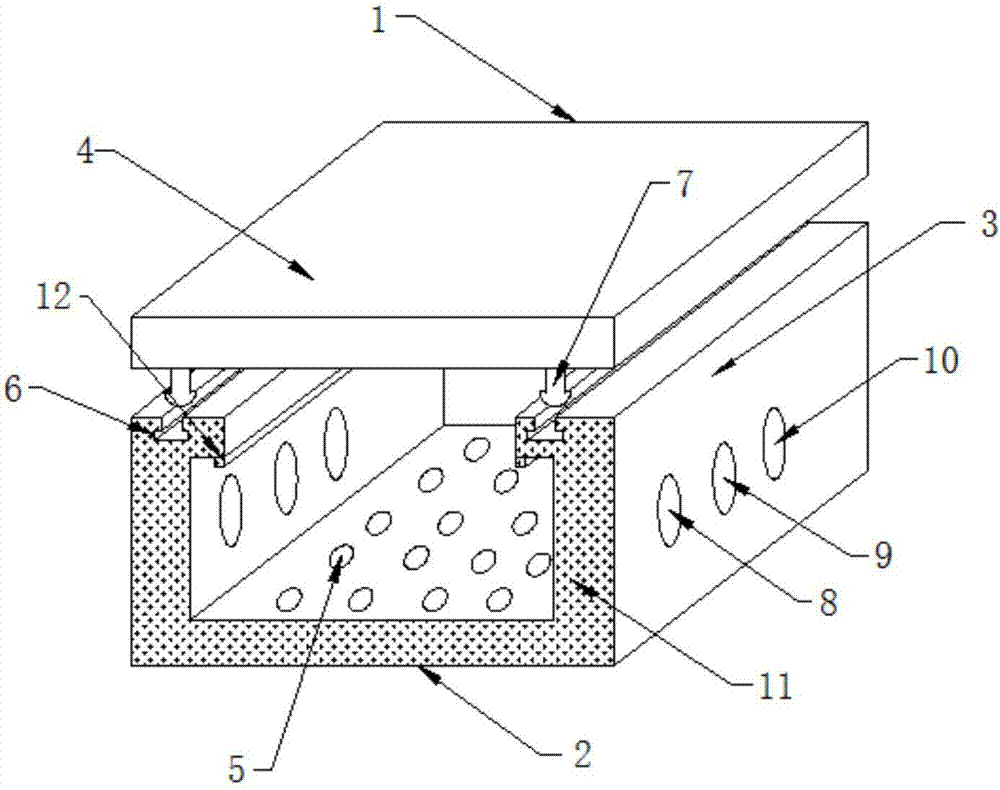

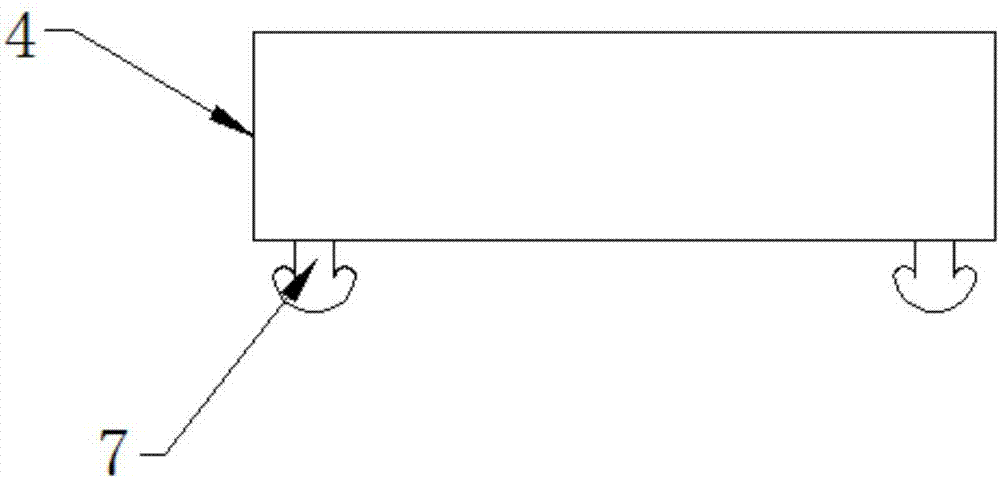

[0026] Such as Figure 1-7 As shown, the present invention provides an aluminum-magnesium alloy cable tray, including a straight-through bridge 1. The straight-through bridge 1 is composed of a bottom plate 2, a side plate 3 and a cover plate 4. Side plates 3 are installed on both sides of the bottom plate 2, and the bottom plate 2 A cover plate 4 is installed on the top, and the cables are laid inside the straight-through bridge 1. The surface of the bottom plate 2 is provided with cooling holes 5, which facilitate the heat dissipation of the cables in the straight-through bridge 1 and prevent burning caused by high temperature. The top of the side plate 3 is provided with a concave Groove 6, the bottom end of cover plate 4 is fixedly equipped with elastic hook 7, the bottom of elastic hook 7 is elliptical, and the side of groove 6 is buckled and installed, so that the connection between cover plate 4 and side plate 3 is more fixed , the outer surface of the side plate 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com