Damage monitoring device and method of conveyer belt of belt conveyer

A belt conveyor and monitoring device technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of low sensitivity, high false alarm rate, conveyor belt damage, etc., and achieve high sensitivity , low false alarm rate, and short hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

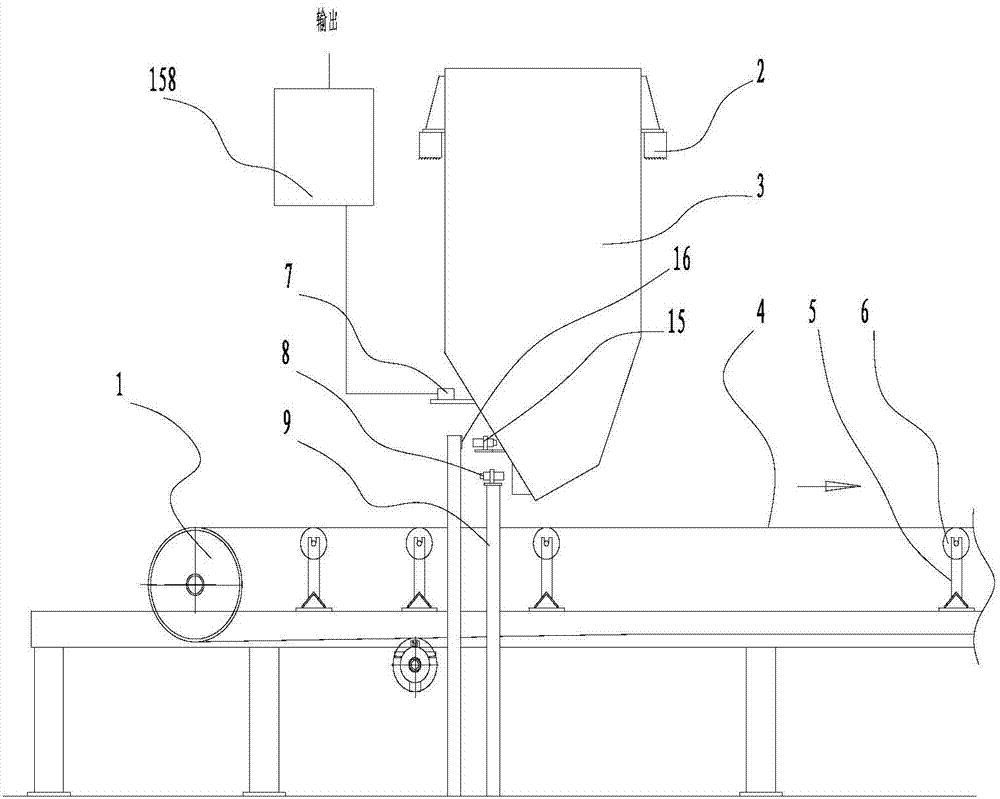

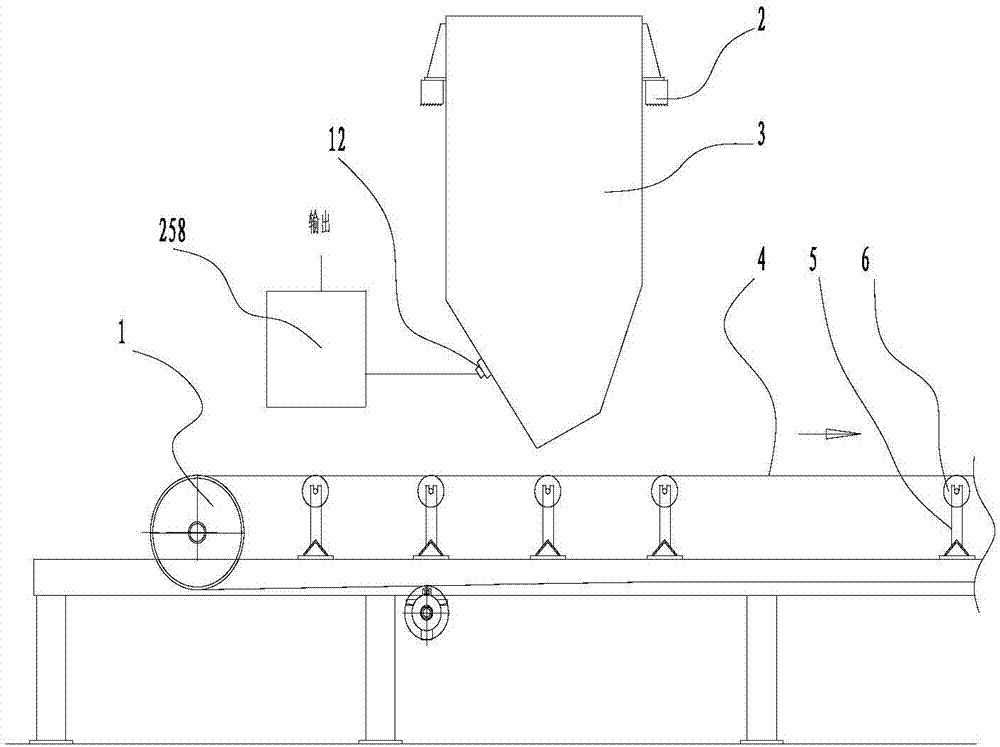

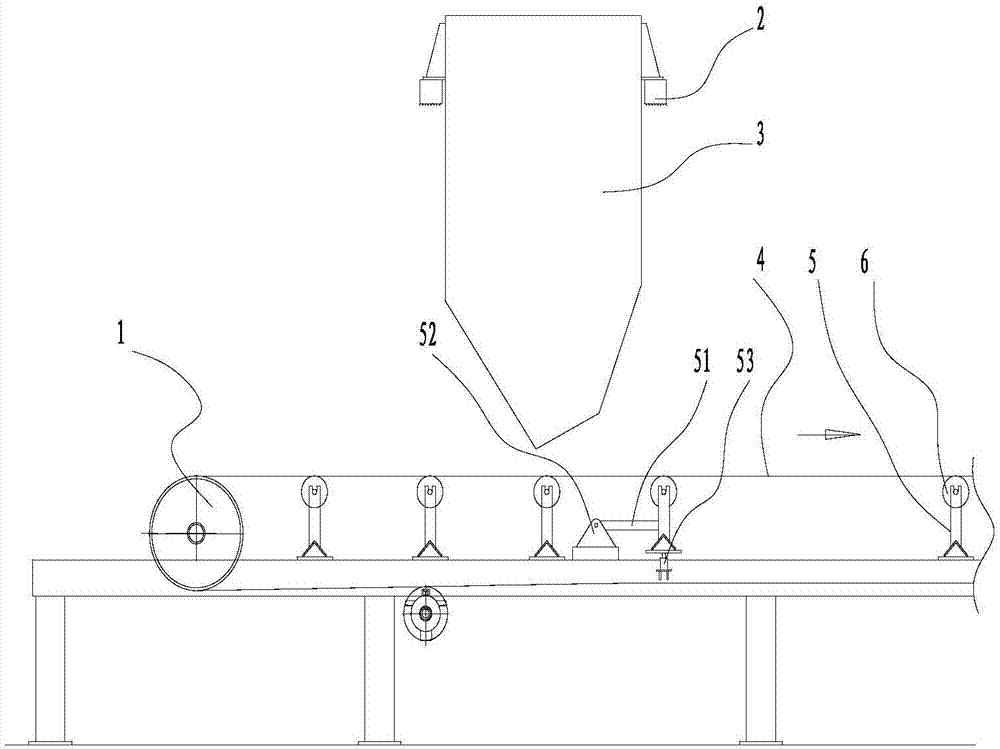

[0066] Option 1. The conveyor belt damage monitoring device of the belt conveyor, including the conveyor belt 1, the bracket 2, the roller 3, the roller 4, etc., is characterized in that: a material receiving body 7 is installed above the conveyor belt, and the material receiving body 7 can be a silo, a chute, a funnel, etc., and a sensor 8 for measuring motion or state is installed on the shell of the material receiving body 7 or an additional structure fixed to the shell. The sensor 8 can be an acceleration sensor, a speed sensor , Displacement sensor, vibration sensor, gyroscope, attitude sensor. Normally, the lower part of the bearing body is suspended in the air, and the upper part is fixed and in a static state. When there is a large volume or long foreign matter stuck between the outlet of the material receiving body and the conveyor belt, the conveyor belt transmits a force in the moving direction of the conveyor belt through the foreign matter stuck at the outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com