Pasted piece dryer

A dryer and patch technology, applied in dryers, drying, progressive dryers, etc., can solve the problems of high temperature of the patch, quality impact, and the patch is not fastened, and prevent the temperature Too low, the effect of preventing the temperature from being too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

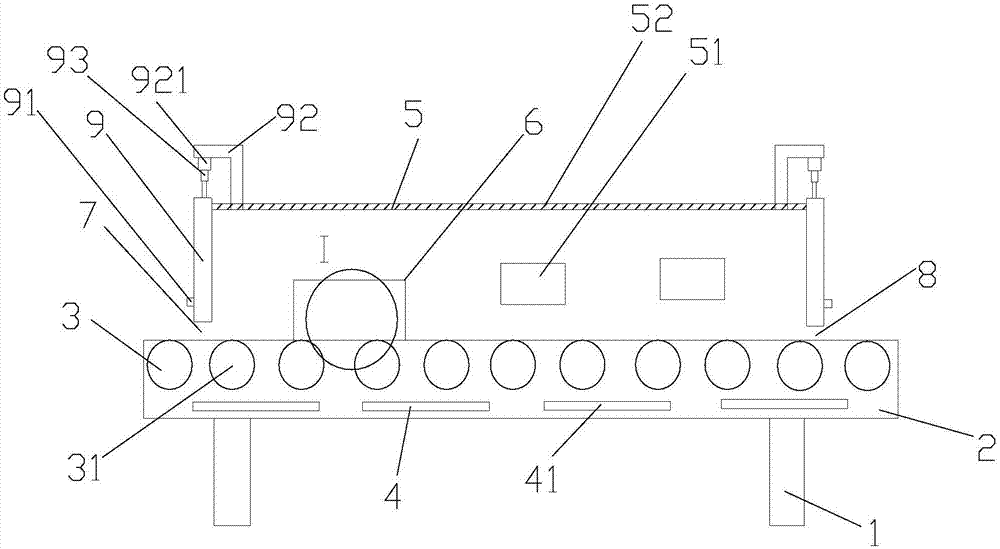

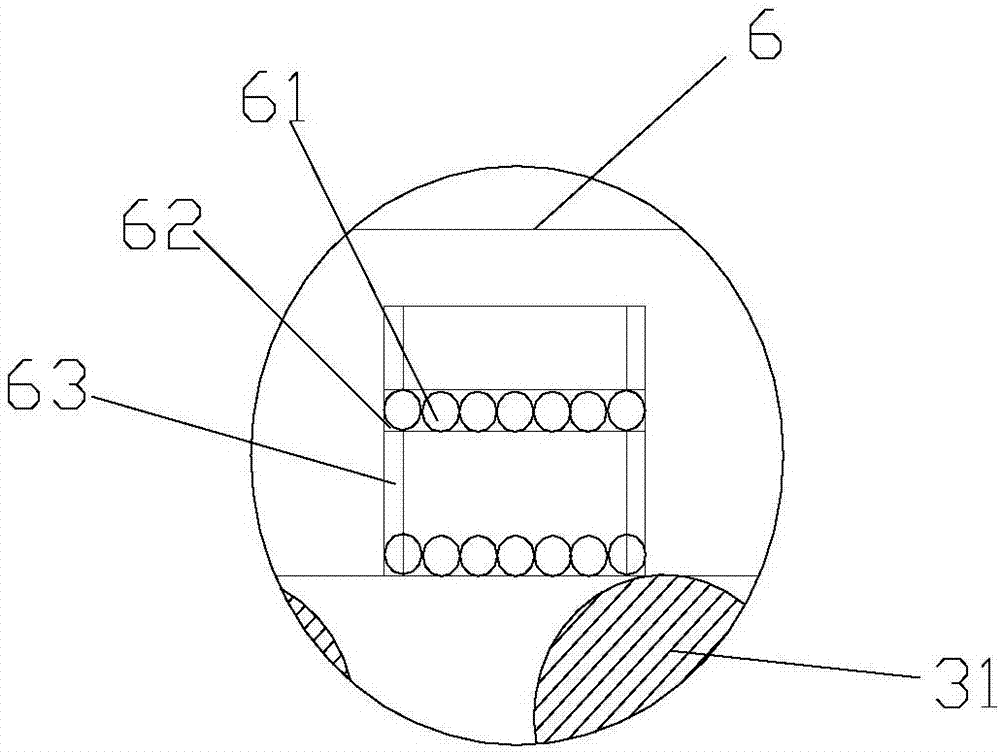

[0017] like figure 1 , figure 2 As shown, a patch dryer includes a bracket 1, a base 2 is arranged on the bracket 1, a conveying device 3 is arranged on the base 2, a drying device 4 is arranged under the conveying device 3, and a cover is arranged outside the conveying device 3 The cover 5 and the conveying device 3 are provided with a clamping device 6, and the front and back directions of the cover 5 are respectively provided with a feed port 7 and a discharge port 8, and the feed port 7 and the discharge port 8 are respectively provided with stretching baffles 9. An inductor 91 is arranged on the extension and retraction baffle 9, a support frame 92 is arranged on the extension and retraction baffle 9, an air pump 921 is arranged on the support rod 92, and a connecting rod 93 is arranged between the extension and retraction baffle 9 and the air pump 921 , A number of ventilation baffles 51 are provided on both sides of the cover 5 .

[0018] In order to ensure that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com