Air valve outer surface detecting device capable of automatically marking fault parts

An automatic marking and detection device technology, applied in the direction of mechanical roughness/irregularity measurement, workshop equipment, manufacturing tools, etc., can solve problems such as unqualified and unable to detect the outer surface of the valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the technical solution of the present invention will be described in detail through specific examples.

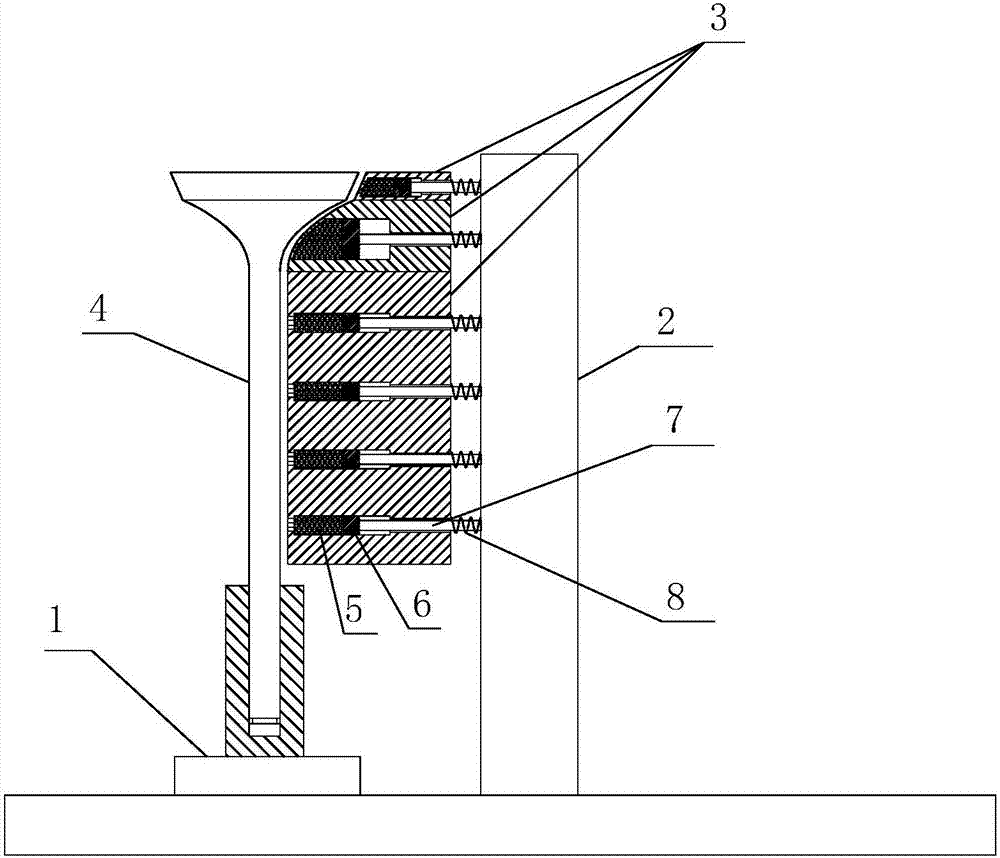

[0017] like figure 1 as shown, figure 1 It is a structural schematic diagram of a valve outer surface detection device that automatically marks problematic parts proposed by the present invention.

[0018] refer to figure 1 , the embodiment of the present invention proposes a valve outer surface detection device that automatically marks problem parts, including: a rotating seat 1, a vertical rod 2, a detection body 3 and a driving mechanism, wherein:

[0019] The rotating seat 1 is provided with vertically arranged slots, and a locking mechanism is provided in the slots. The rotating seat 1 is connected with the driving mechanism and can be driven by the driving mechanism to rotate in the horizontal direction; when one end of the air supply valve 4 is inserted into the slot, , use the locking mechanism to fix the valve 4, so that the valve 4 can maintain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com