Method for detecting local interlayer peeling position of composite material board

A composite material board and detection method technology, applied in the direction of analyzing materials, using sound waves/ultrasonic waves/infrasonic waves for material analysis, measuring devices, etc., can solve problems that are difficult to meet and affect detection results, and achieve the elimination of environmental noise. Meaning, effect that reinforces the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0035] Those skilled in the art can understand that, unless otherwise defined, all terms (including technical terms and scientific terms) used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs.

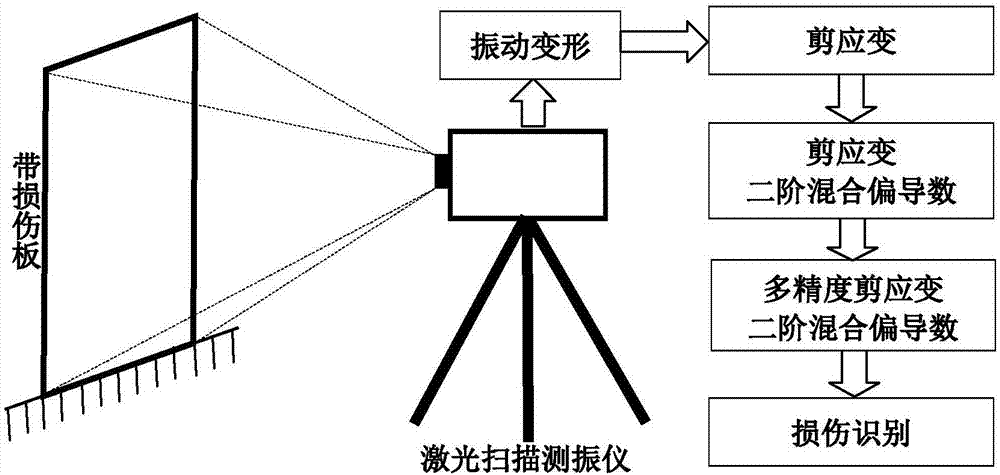

[0036] Such as figure 1 As shown, the method for detecting the local interlaminar peeling position of the composite material plate proposed by the present invention comprises the following steps:

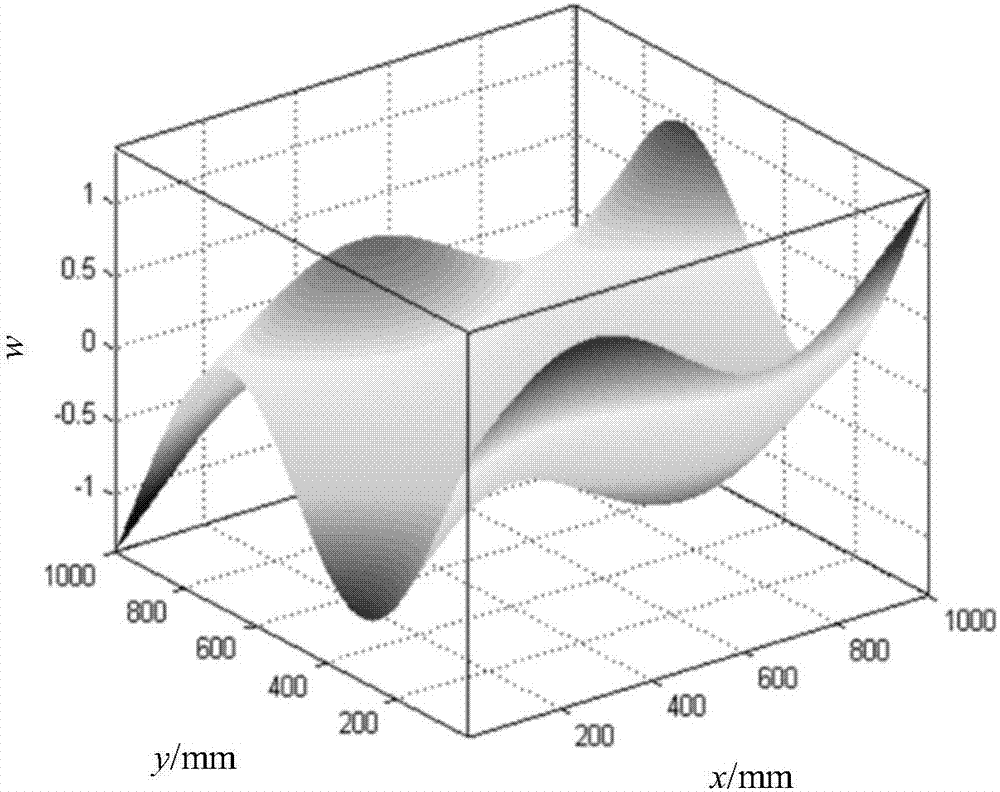

[0037] 1. Obtain the vibration deformation w(x,y) of the composite material plate;

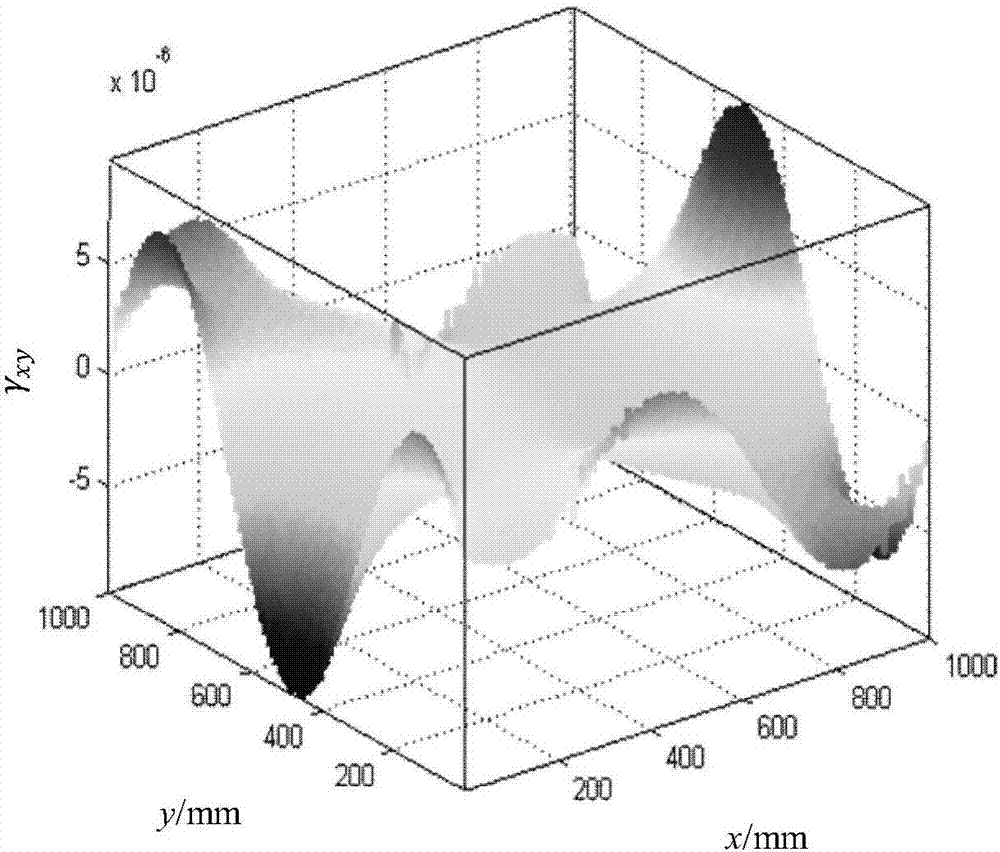

[0038] 2. Substitute w(x,y) into the shear strain formula of the plate to obtain the shear strain γ xy (x,y):

[0039]

[0040] Among them, x, y, and z are the coordinates of the length, width, and thickness directions of the plate, respectively.

[0041] 3. Apply the second-order mixed partial derivati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com