Integrally-formed towel rack with mounting screws

A towel rack and screw technology, which is applied in the field of integrally formed towel racks with installation screws, can solve the problems of prolonged installation time, low efficiency, and cumbersomeness, and achieve the effects of small installation steps, improved installation efficiency, and small structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

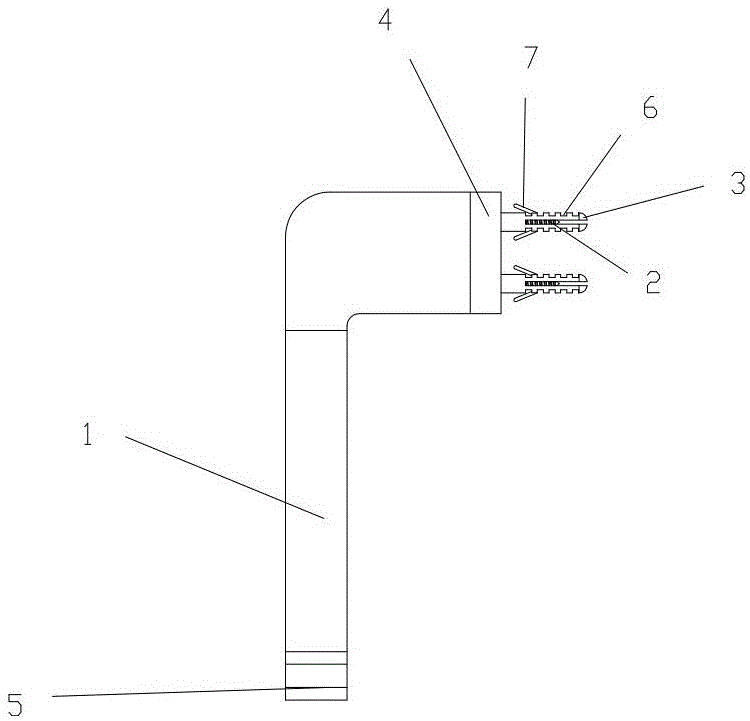

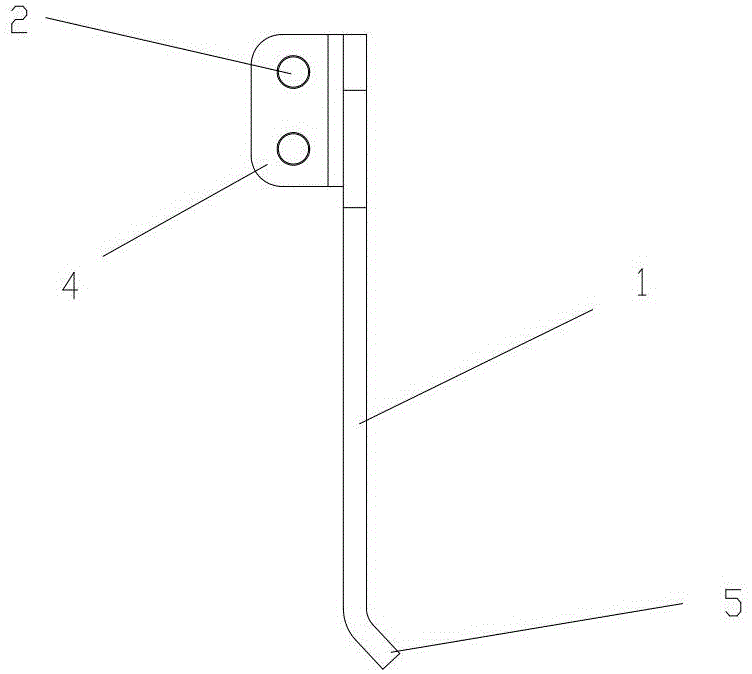

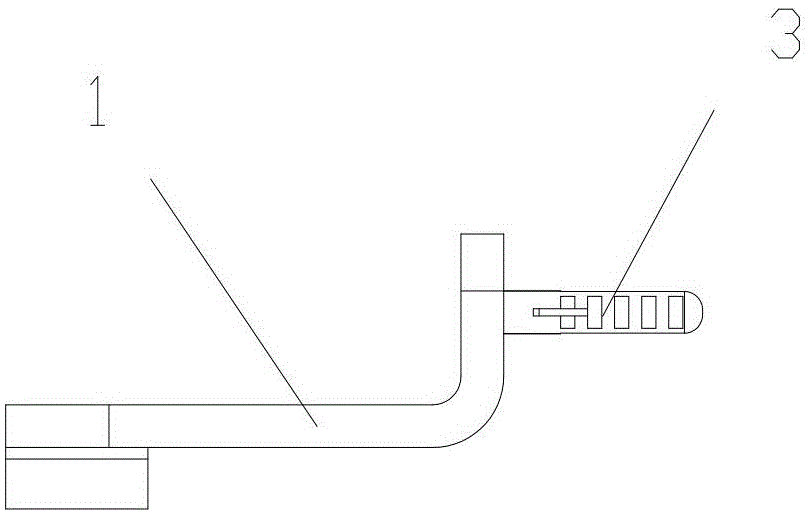

[0012] An integrated towel rack with mounting screws described in Embodiment 1, such as figure 1 , figure 2 and image 3 As shown, the main body 1 of the towel rack is included. The installation end faces of the two ends of the main body of the towel rack are provided with mounting screws 2 which form an integral structure with the main body of the towel rack. The dead form is fixedly installed with the mounting screws; the main body of the towel rack and the mounting screws are also provided with a connecting gasket 4, and the connecting gasket and the main body of the towel rack form an integral connection structure; the main body of the towel rack is a hanging rod , the end of the hook end 5 of the hanging rod is tilted up to prevent the towel from slipping, and the tilt angle is 137°.

[0013] In this embodiment, the side of the explosion-proof rubber sleeve is provided with a plurality of groove openings 6 for preventing sliding with the installation wall, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com