Filter and filtering and cleaning method thereof

A filter and filter screen technology, applied in chemical instruments and methods, fixed filter element filters, filtration and separation, etc., can solve problems such as affecting the normal flow of the main pipeline, and achieve the effect of convenient and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0048] Example 1

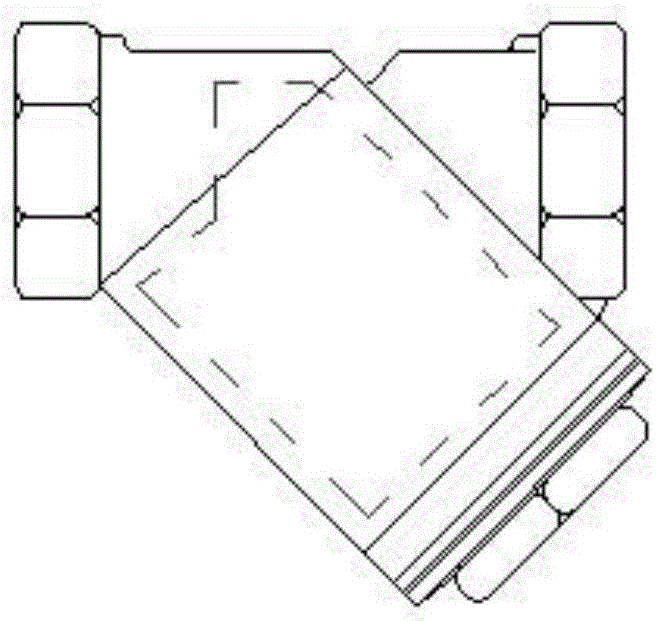

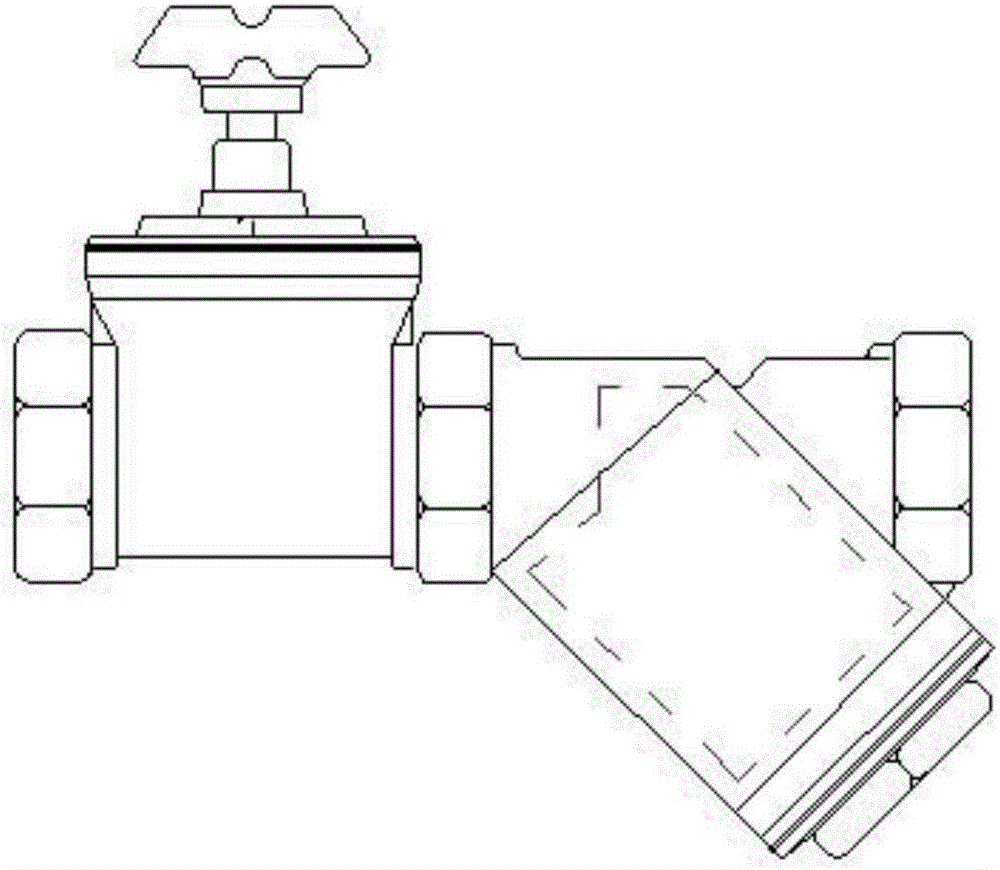

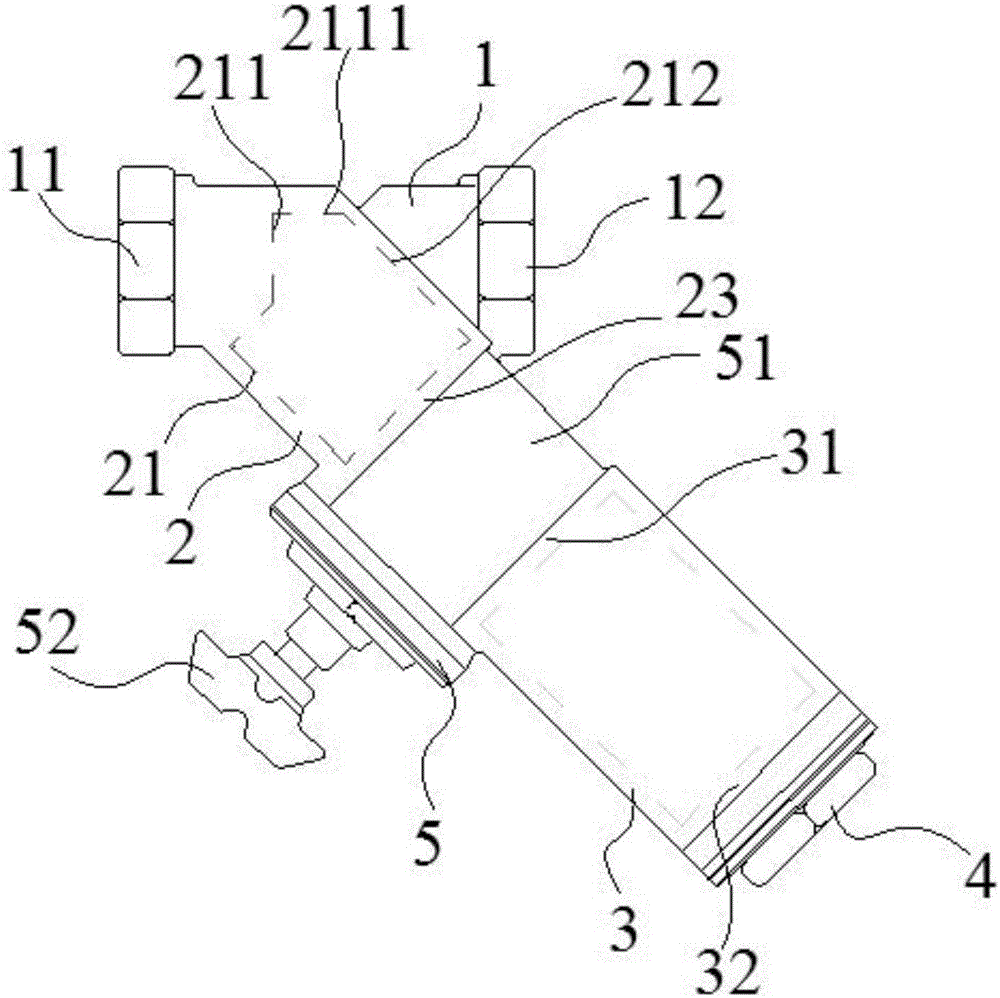

[0049] Such as image 3 As shown, a filter includes an interception lumen 1, a filter mesh 21 and a filter lumen 2. The interception lumen 1 is located on the axis of the main pipeline, and the filter lumen 2 and the interception lumen 1 is connected, the filter mesh 21 is located in the filter tube cavity 2, the filter mesh water intake port 211 of the filter mesh 21 is located in the interception tube cavity 1, and the filter mesh water intake port 211 is directly facing the liquid flow direction. It includes a valve 5 and a sedimentation chamber 3. One end of the valve 5 communicates with the end of the filter tube cavity 2 away from the interception tube 1, and the other end of the valve 5 communicates with the sedimentation chamber 3.

[0050] The filter mesh water inlet 211 of the filter mesh 21 of the filter is directly facing the liquid flow direction on the main pipe, so that the filter mesh water intake port 211 of the filter mesh 21 intercepts impurit...

Example Embodiment

[0056] Example 2

[0057] Such as image 3 As shown, a filter of this embodiment is different from Embodiment 1 in that the water inlet 211 of the filter 21 includes a top surface 2111 of the filter and a side surface 212 of the filter, and the water inlet 211 of the filter The edge of the filter mesh and the top surface 2111 of the filter are in contact with the inner wall of the interception lumen 1, the top surface 2111 of the filter is in contact with the highest point of the inner wall of the interception lumen 1, and the lowest point of the water inlet 211 of the filter is in contact with the interception lumen 1.

[0058] In order to prevent the liquid from not passing through the interception effect of the filter screen 21, from the interception lumen 1 directly into the main pipeline behind the interception lumen 1, affecting the water quality index content in the main pipeline, the filter 21 and the interception lumen 1 and the filter lumen The fit design of 2 is zero fi...

Example Embodiment

[0059] Example 3

[0060] Such as image 3 As shown, a filter of this embodiment is different from Embodiment 1 or 2 in that the angle between the axis of the filter lumen 2 and the axis of the interception lumen 1 is 30°-45°. In specific applications, you can choose to set angle values such as 30°, 45°, 35°, 40°, 38°, and 43°.

[0061] The filter screen 21 is located in the filter tube cavity 2, and the angle between the axis of the filter screen 21 and the axis of the interception tube cavity 1 is 30°-45°. The impurities pass through the water inlet 211 of the filter screen and are intercepted by the filter screen side 212 of the filter screen 21 When it comes down, the intercepted impurities will fall into the filter mesh 21 under the action of gravity and the scouring effect of the liquid, and enter the sedimentation chamber 3 along the direction of the filter lumen 2. When the angle is in the range of 30°-45° , The impurities will not be blocked on the side 212 of the filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axis angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com