Universal movable large-sized workpiece turnover device

A technology of large workpiece and turning device, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of turning large precision workpieces, etc., to achieve good load sharing, reduce wear, and reduce the degree of rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

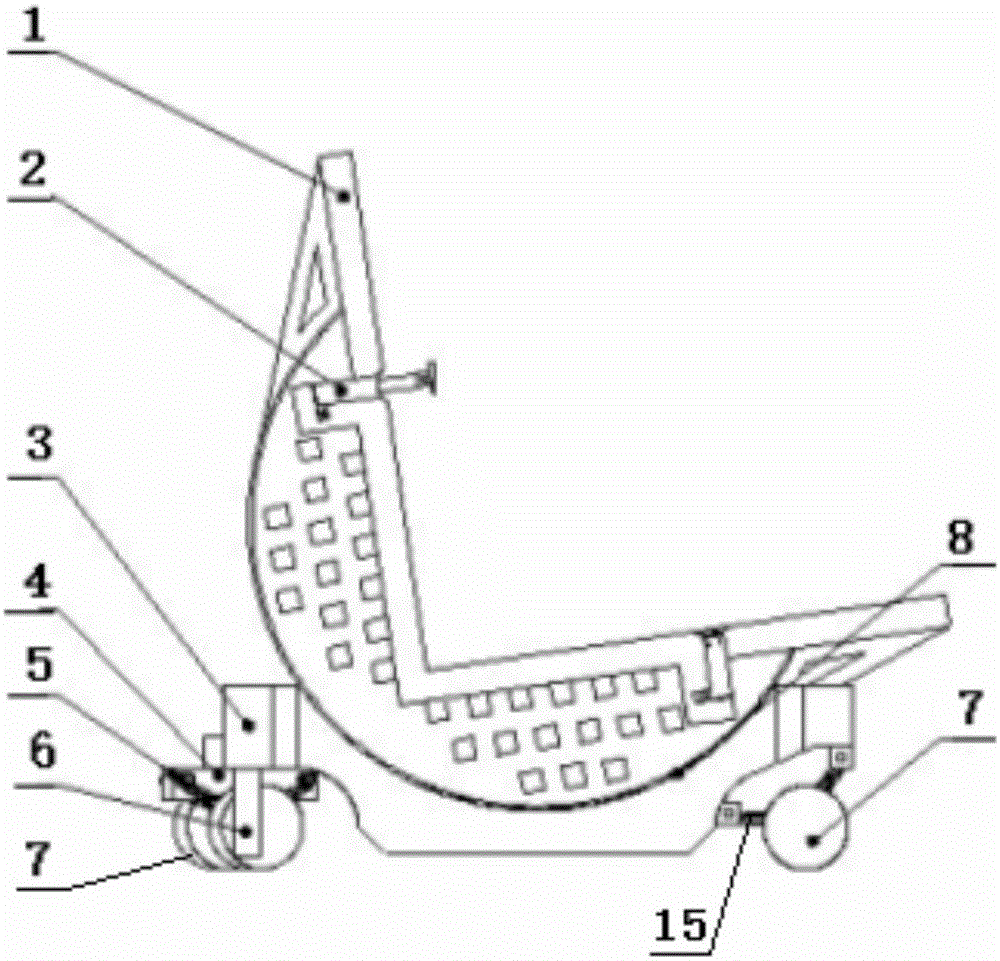

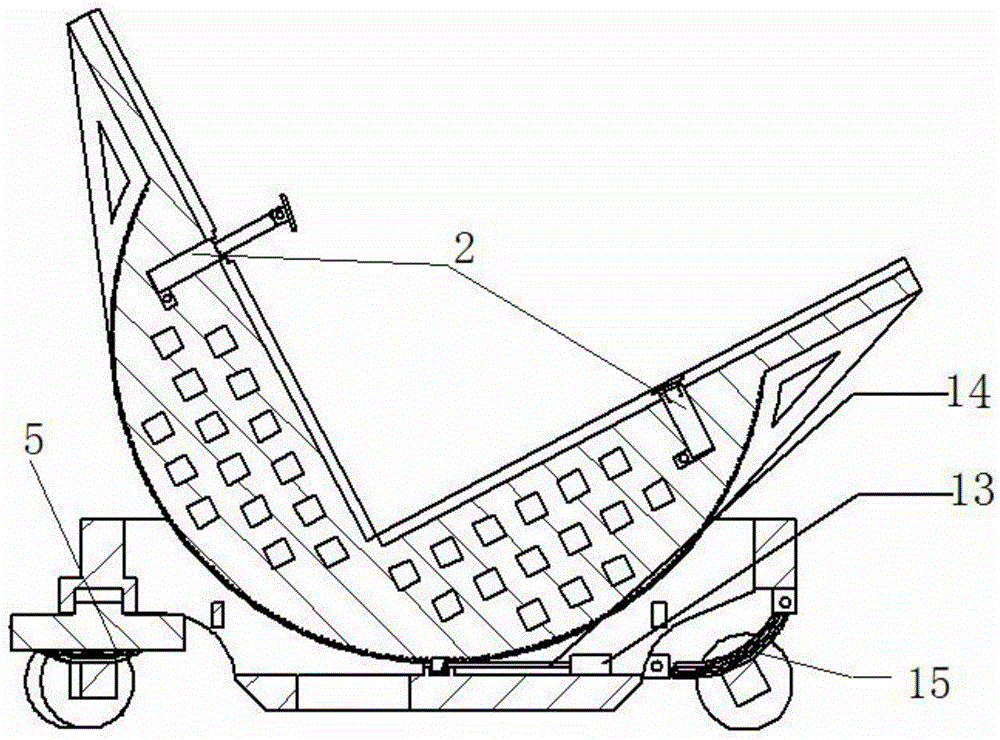

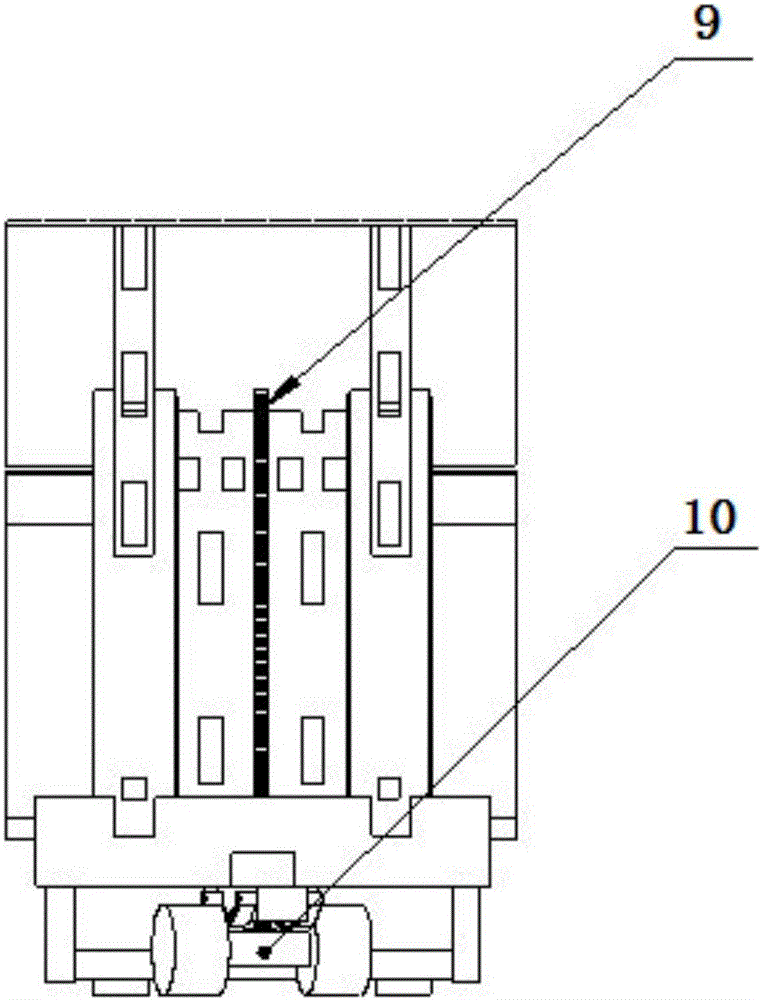

[0030] Such as Figure 1-7 As shown, a general movable overturning device for large workpieces includes an overturning platform 1 and an overturning support frame 3, the overturning platform 1 has a right-angle workbench, and the overturning support frame 3 is connected with the overturning platform 1 through a worm gear mechanism; The worm 14 is arranged on the turning support frame 3, and the outer surface of the right-angle workbench of the turning platform 1 is provided with a helical tooth 9 matched with the worm 14, and the helical tooth 9 and the worm 14 constitute a worm and gear mechanism. A motor 13 is also installed on the support frame 3, the worm 14 is connected to the motor 13 in transmission, the motor 13 drives the worm 14 to rotate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap