A method for anti-floating of the core mold of the cup mouth column foundation

A technology of cup mouth foundation and column foundation, which is applied in the anti-floating field of cup mouth column foundation mandrel, can solve the problems of inconvenient construction method of cup mouth column foundation mandrel, inability to meet the installation of factory building columns, and the elevation of the bottom of cup mouth, etc., so as to avoid The effect of secondary cleaning work, installation accuracy assurance, and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The method for anti-floating of the core mold of the cup mouth column foundation of the present invention comprises the following steps:

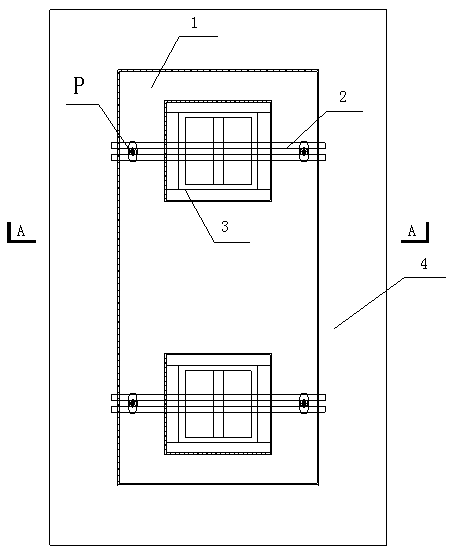

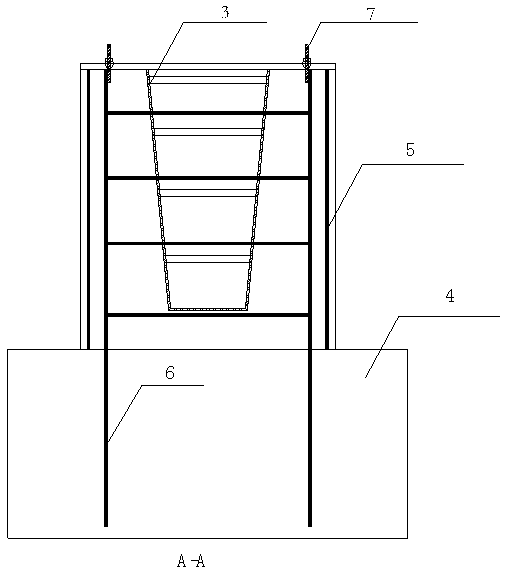

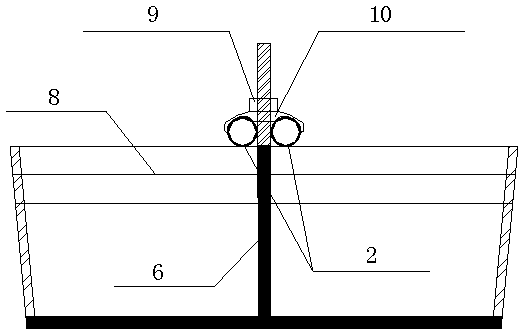

[0025] see now Figure 1-Figure 3 , figure 1 It is a schematic diagram of anti-floating of the core mold of the cup mouth column foundation in the embodiment of the present invention, figure 2 for figure 1 Middle A-A sectional view, image 3 for figure 1 Enlarged view of the middle P site. a. Retain tie bars 6: When the steel bars of the column foundation cap 4 are installed, a tie bar with the same specification and size as the column base cup mouth steel bar is left in the center of the side line corresponding to the column base cup mouth 1 6.

[0026] b. Welding bolt head: After pouring concrete for the cap of the column foundation, install the foundation reinforcement of the cup mouth, support the cup mouth mandrel and the cup mouth side mold, and weld and fix a section of 200mm long full thread on the top of the two tie b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com