Repairing structure and construction method for bulging damage of concrete panels

A technology of concrete panels and concrete, which is applied in the field of repairing engineering similar to damage forms, can solve problems such as low construction efficiency, inadaptability to repairing cracks, damage, etc., and achieve the effects of convenient construction, reduced restraint, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

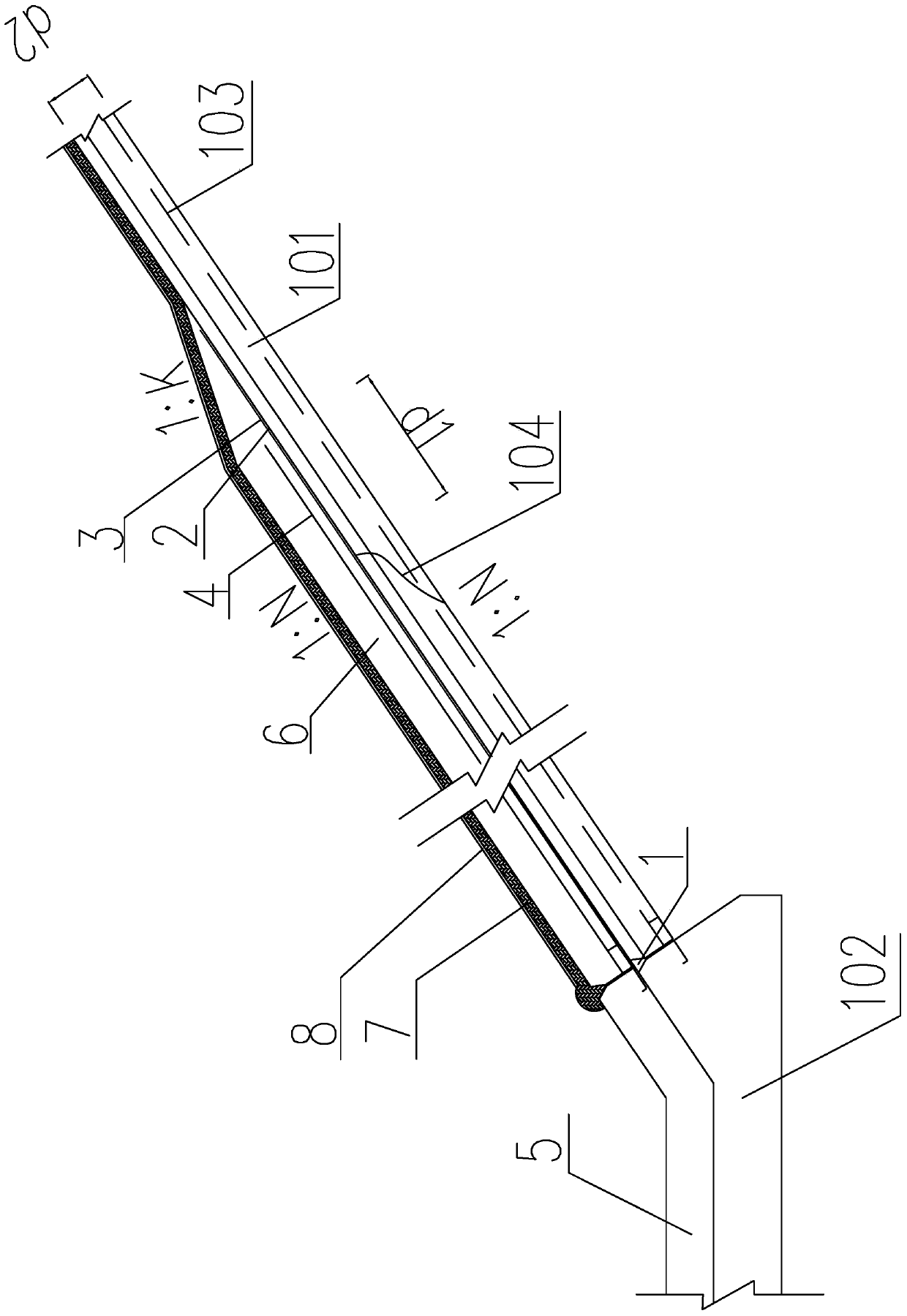

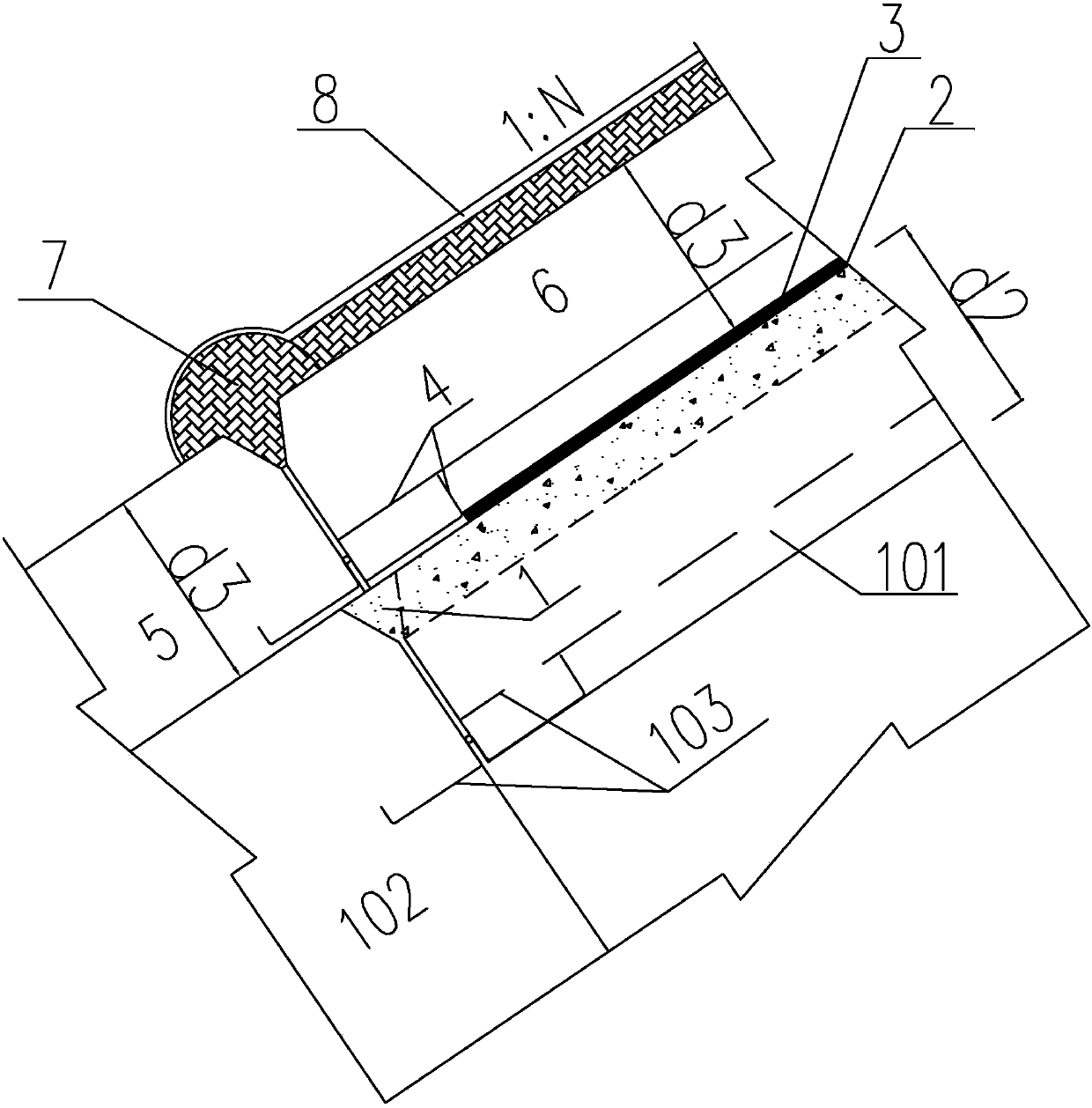

[0022] Such as figure 1 , figure 2 As shown, the present embodiment is a repair structure and construction method for bulging and damaged concrete panels, including old concrete panels 101, old toe boards 102 around the old concrete panels, copper waterstop I 103 installed in the old concrete panels, and old concrete panels. The vertical seam between the concrete face plate 101 and the old toe board 102, the surface waterproofing of the peripheral seam (including the vertical seam, the plastic waterproof filler in the V-shaped groove on the top of the peripheral seam, the seepage protection cover, the fixed flat steel / angle steel, the fixed bolts, etc.), the upper part of the old concrete panel 101 has a number of cracks, and the uppermost crack 104 is the main control factor for determining the repair area, that is, the repair range is the outward or upward expansion distance d1 of the crack 104; Repair the surface waterproofing of the vertical joints and peripheral joints ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com