Centralized control type low-temperature radiation electrothermal film heating system construction method

A heating system and low-temperature radiation technology, applied in the field of heating construction, can solve the problems of no certain development prospects, large air pollution, no energy saving and environmental protection, etc., and achieve the effects of avoiding wall drilling, saving water resources, and facilitating pipeline optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

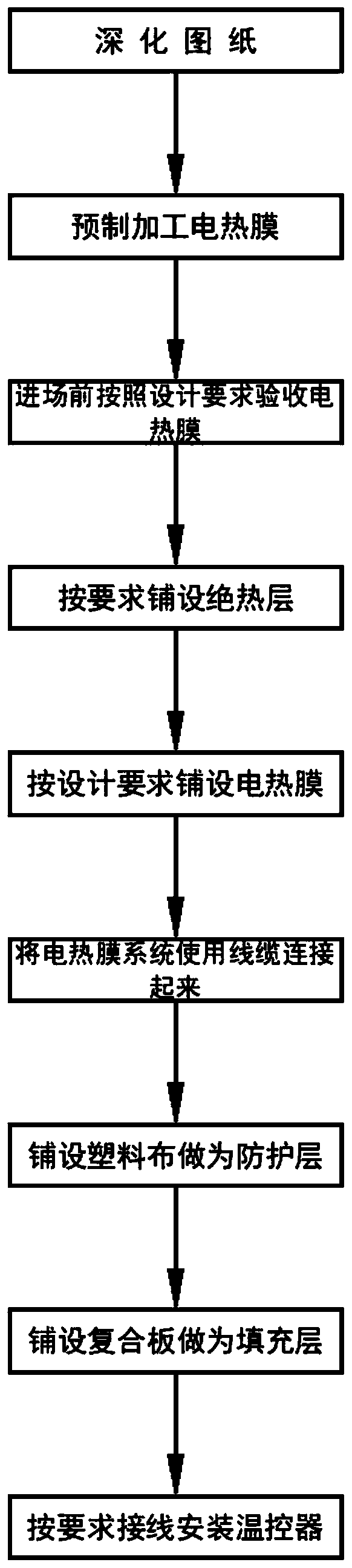

[0040] The concrete realization of this embodiment is described in detail below:

[0041] (1) Deepen drawings

[0042] Deepen the laying of the electric heating film and the connection points, and avoid the lower corners of the door frame, the corners of the walls and the places where the water and electricity pipes are densely populated. Avoid the impact of chiseling on the electric heating film in the later stage.

[0043] According to the characteristics of the standard room and the detailed size, prefabricated connection and assembly of some connecting cables.

[0044] (2) Prefabricated and processed electric heating film

[0045] The manufacturer processes the electric heating film according to the specifications and dimensions of the deepened electric heating film.

[0046] (3) Check and accept the electric heating film according to the design requirements before entering the site and check whether the initial ground where the electric heating film is laid is up to st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com