Substrate processing device

A substrate processing device and substrate technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of narrowing the range of material selection and inability to form holding parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0127] The present invention is not limited to the contents of the above-described embodiments, and various changes can be made within the scope of the present invention.

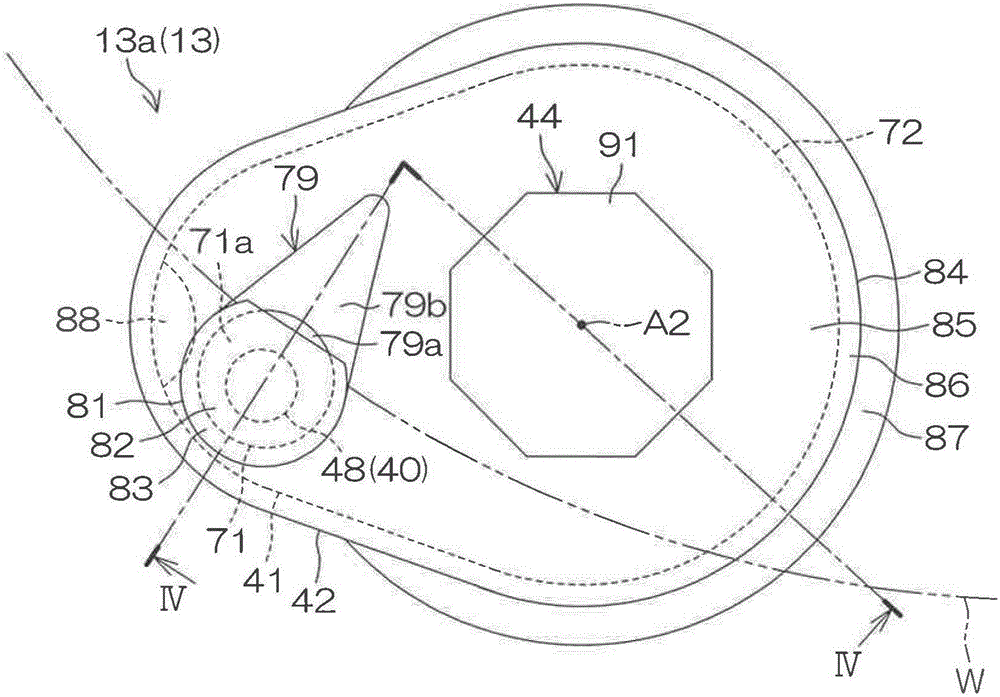

[0128] For example, in the above-mentioned embodiment, the case where the jig cover 42 covers the entire exposed portion of the conductive member 41 in a plan view has been described, but the jig cover 42 may cover only a part of the exposed portion in a plan view. The jig cover 42 may also be omitted.

[0129] The softening temperature of the entire core material 40 may be the same as or lower than the softening temperature of the entire conductive member 41 . Likewise, the strength of the entire core material 40 may be equal to or lower than the strength of the entire conductive member 41 .

[0130] At least one of the upper facing portion (lower surface 91 a ) of the current conducting member 44 and the lower facing portion (hook portion 88 ) of the jig cover 42 may be omitted as long as the jig cover 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com