Low temperature drift wall pressure sensor

A pressure sensor, low temperature drift technology, used in the measurement of blasting force and other directions, can solve the problems of poor shock and vibration resistance, low sensitivity, poor stability, etc., to achieve good anti-corrosion and shock resistance, low temperature drift performance.

Active Publication Date: 2012-12-19

BEIJING INSTITUTE OF TECHNOLOGYGY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the field explosion test, this kind of wall pressure sensor not only has to withstand the transient explosion and impact, but also has to withstand the changeable field environmental temperature field, and sometimes also has to withstand the effects of rain and moisture. Pressure sensors, some semiconductor sensors, have poor shock and vibration resistance, poor stability, and poor waterproof and sealing performance in complex and harsh environments. Manganin piezoresistive sensors have better performance, but their sensitivity is too low; The sensor for measuring wall pressure in the explosion pressure field must have the following properties: wide enough range, such as the upper range is 50Mpa, the lower range is 0.5MPa; high enough sensitivity, such as 10pc / Mpa ~ 100MPa; sufficiently low temperature drift , such as 0.01pc / ℃~0.001pc / ℃; it has the performance of water sealing and has strong shock and vibration resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Login to View More

Abstract

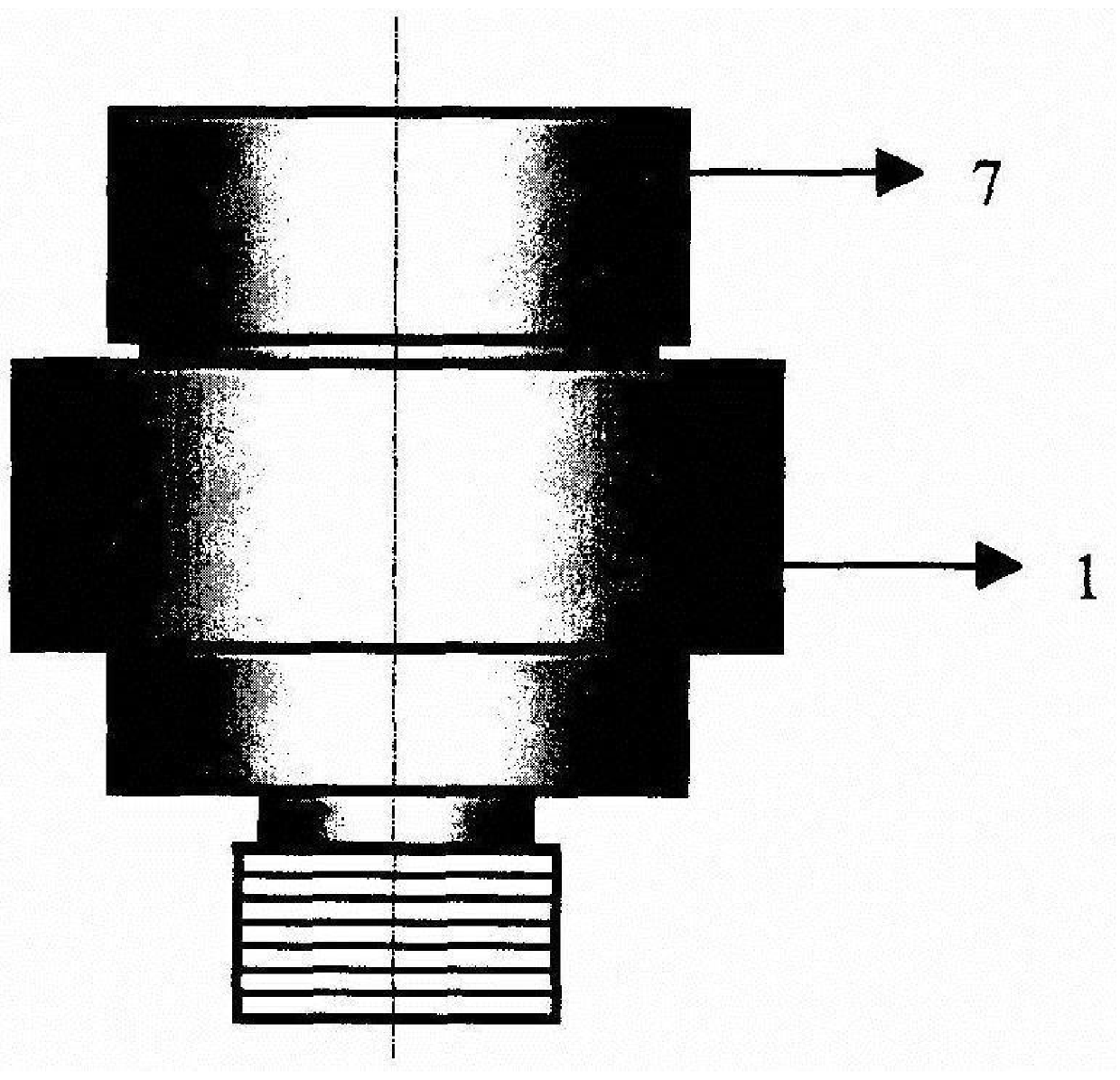

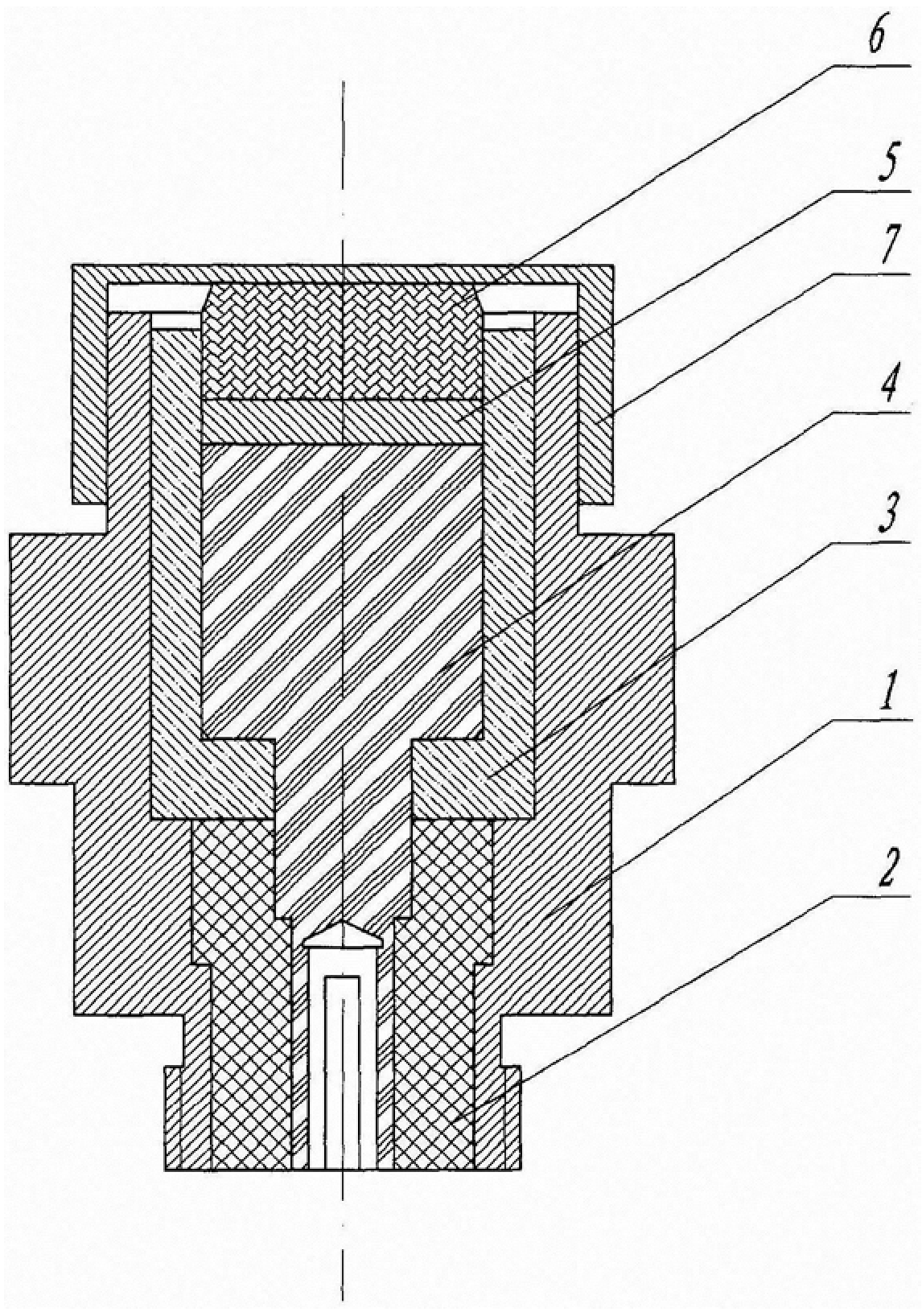

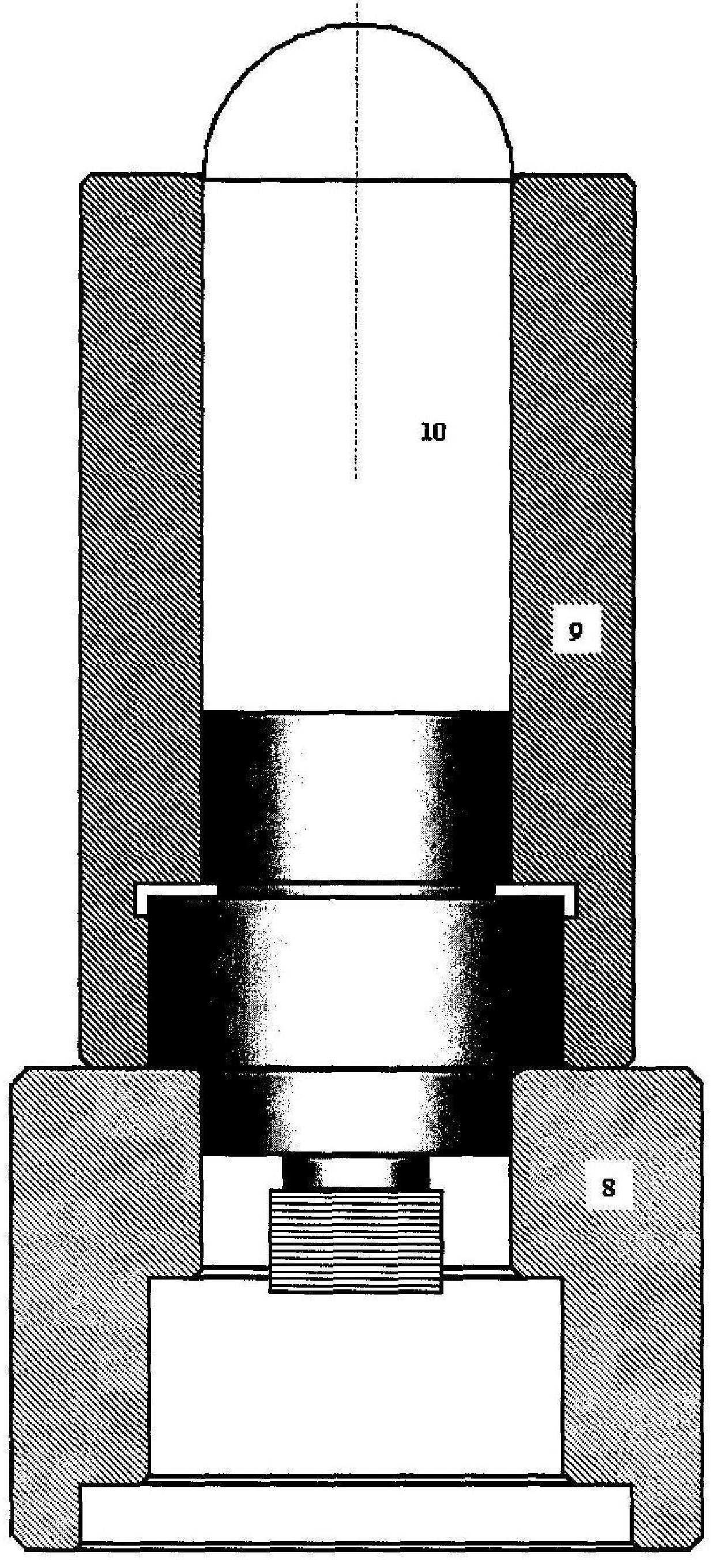

The low temperature drift wall pressure sensor used in the present invention is used as a sensor for measuring wall shock wave pressure or ground surface shock wave pressure. The low temperature drift wall pressure sensor has a wide range, high sensitivity and low temperature drift performance, and it includes a stainless steel shell. Body, polytetrafluoroethylene insulating sleeve, plexiglass positioning sleeve, phosphor bronze core electrode, quartz piezoelectric element, gasket and elastic element, the low-temperature drift wall surface can achieve close connection with low-noise cables, and has good corrosion resistance, Impact-resistant, water-tight and acoustically insulating.

Description

technical field The invention belongs to the technical field of explosion pressure field measurement, in particular to a low-temperature drift wall surface pressure sensor structure. Background technique When measuring the pressure acting on the surface of the component or measuring the pressure acting on the surface of the ground in the air explosion or water explosion pressure field, a wall pressure sensor must be used; when installing this sensor, the surface of the sensitive part of the sensor must be in line with the surface of the measured component Flush, or flush with the surface near the measuring point. In the field explosion test, this kind of wall pressure sensor not only has to withstand the transient explosion and impact, but also has to withstand the changeable field environmental temperature field, and sometimes also has to withstand the effects of rain and moisture. Pressure sensors, some semiconductor sensors, have poor shock and vibration resistance, poor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01L5/14

Inventor 段卓平黄正平黄风雷张连生

Owner BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com