Bar-type screen cage

A sieve cage and strip technology, applied in the direction of filter screen, fixed filter element filter, grille, etc., can solve the problems of high cost, difficult to reliable groove width, etc., and achieve the effect of durable connection, high stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

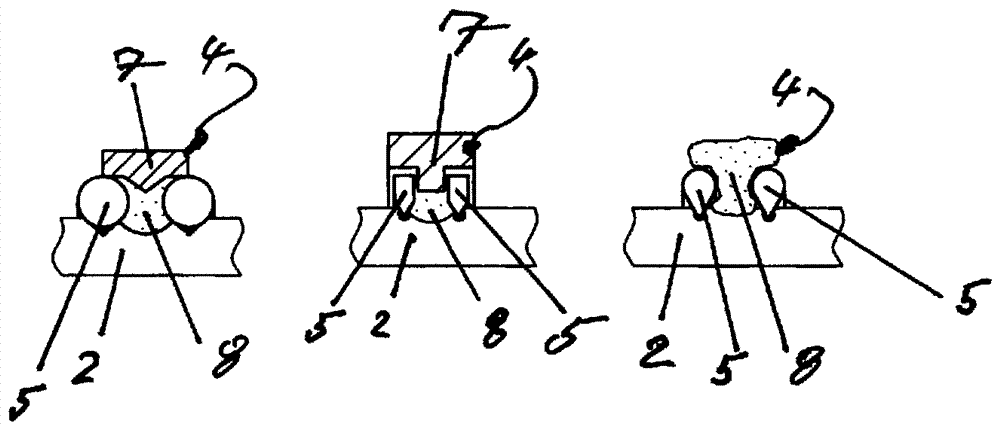

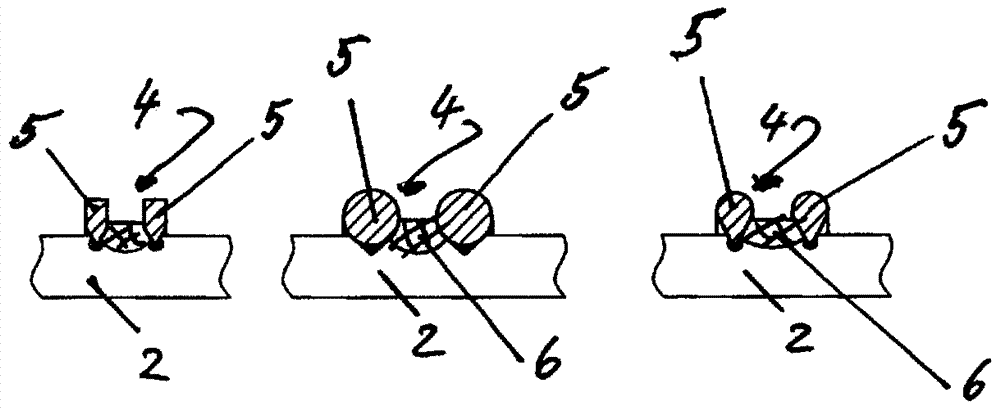

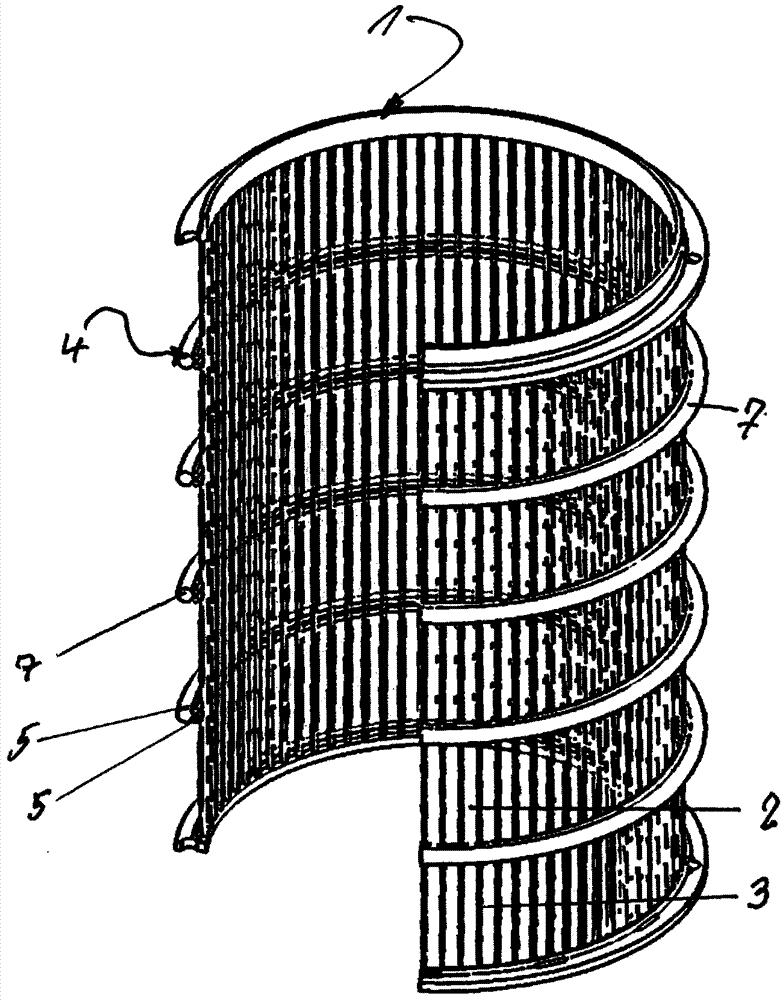

[0024] figure 1 with 2 Shown is a screen cage, generally indicated with reference number 1 , having circumferentially spaced profiled bars (profile bars) 2 with screen slots 3 with predetermined openings delimited between the bars. Slot width. The screen cage 1 also comprises a plurality of support arrangements indicated with reference numeral 4, spaced apart in the axial direction of the screen cage 1 and fastened on the outside of the screen bars 2 by means of welding. as in as figure 1 with 2 The perspective view of the enlarged cross-sectional view of image 3 As can be particularly seen in , each support arrangement 4 comprises at least two support wires 5 spaced apart in the axial direction of the bar 2 . These support wires 5 are fastened to the bars by means of resistance welding. An additional weld seam, indicated with reference numeral 6 , is provided, which fixedly connects the two support wires 5 of each support arrangement 4 with the profile bar or profile b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com