Scissor arm assembly for a scissor lift of aerial work platform

A technology of working platform and lifting mechanism, applied in the direction of lifting frame, lifting device, etc., can solve the problems of weakened beams, scissor beams, complex manufacturing, and difficult parts accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The following will refer to Figure 6 to Figure 15 Preferred embodiments of the present invention are described.

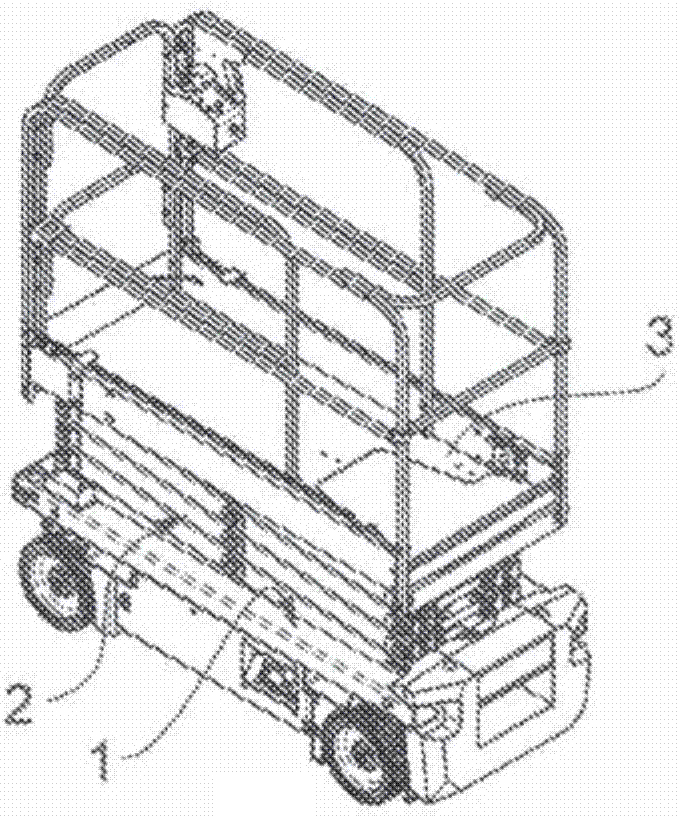

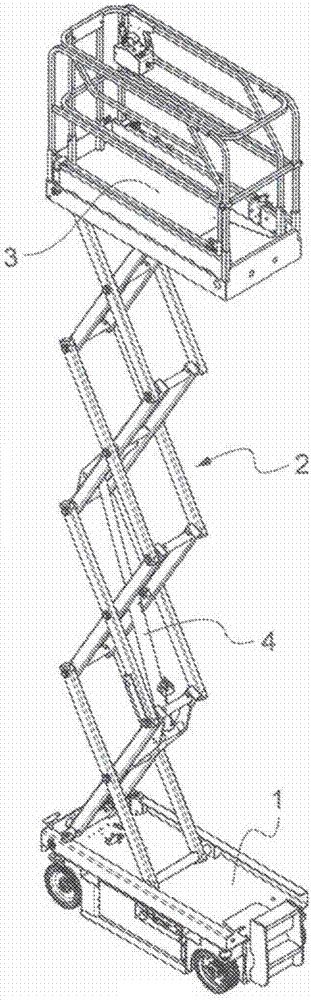

[0065] Figure 6 shows the setting as an alternative to the figure 1 and figure 2 of aerial work platforms image 3 An overall view of the scissor lift mechanism of the prior art scissor lift mechanism.

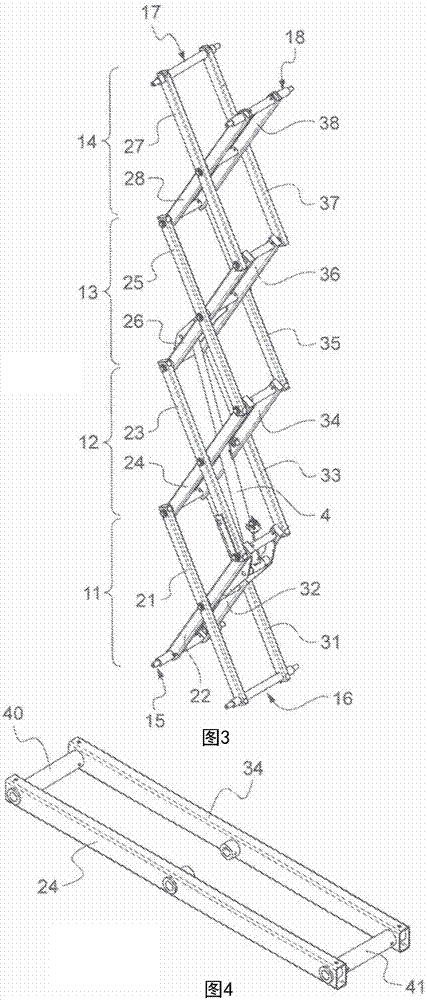

[0066] The overall structure of the lifting mechanism and image 3 similar. As the latter, it consists of two sets of parallel scissors at a distance from each other. Each set of scissors consists of several pairs of tubular beams joined together at their centers like scissors, a plurality of such scissors mounted one above the other by their joined ends: see the stack defining the first set The four pairs (121,122), (123,124), (125,126) and (127,128) of the scissors and the four pairs (131,132), (133,134), (135,136) and (137,138) of the stacked scissors defining the second set. The sections of the tubular beam are preferably rectangular or square...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com