Rotor for outer rotor brushless electric motor

A technology of brushless motors and external rotors, applied in the direction of synchronous motors with stationary armatures and rotating magnets, electric components, electrical components, etc., can solve the problem of motor looseness and misalignment, operation that increases rotor costs, and increases rotor costs And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

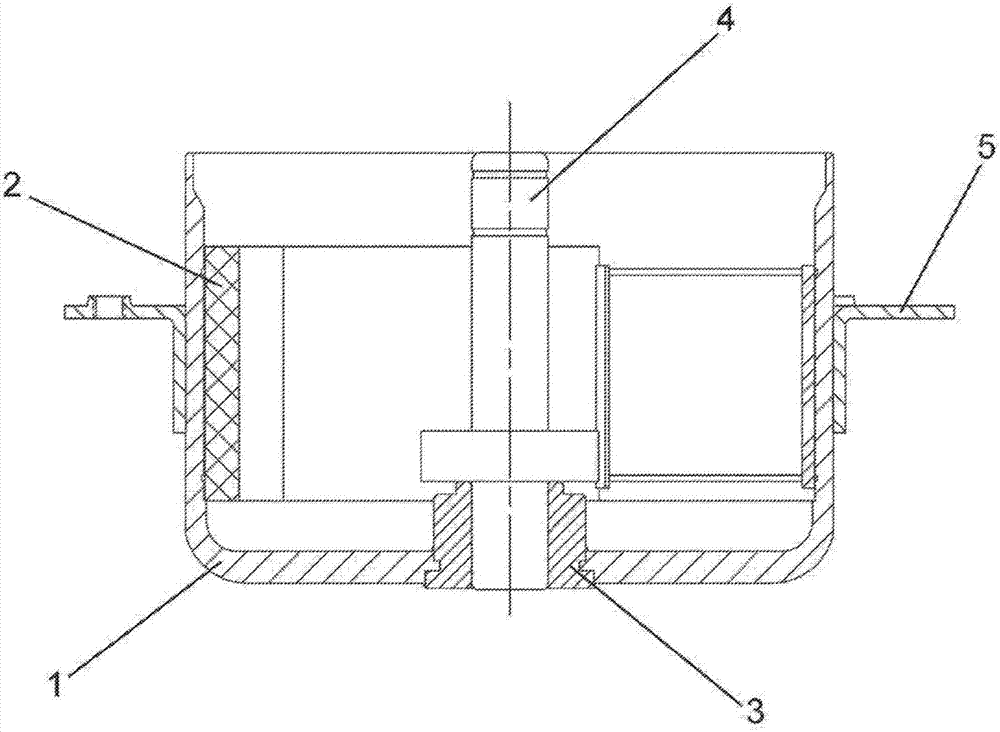

[0016] The object of the invention is a rotor for an external rotor brushless motor which has been developed according to an embodiment which improves the rotor conventionally used in said application, e.g. figure 1 Shown is a rotor having a housing 1 formed by press-forming an iron plate, on which magnets 2 are provided on the inner part to define the operation of the rotor in the applied electric machine.

[0017] In said type of rotor, the casing 1 made of iron plate requires secondary incorporation of the bushing 3 for holding the shaft 4 that assembles the rotor in the applied motor, and the incorporation of the flange 5 into the On the outer part for holding elements that must rotate with the rotor, such as the propeller of an axial fan or the impeller of a radial fan, the incorporation of said bushing 3 and said flange 5 requires supplementary assembly and fixing operations, These operations increase the cost of the rotor and make the rotor prone to play and misalignmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com