Fully automatic fertilizer applicator

A fertilizer applicator, fully automatic technology, applied in fertilization devices, fertilizer dispensers, applications, etc., can solve the problems of difficult control of feeding, user discomfort, waste of manpower and material resources, etc., to reduce hand injuries and improve fertilization efficiency , to avoid the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

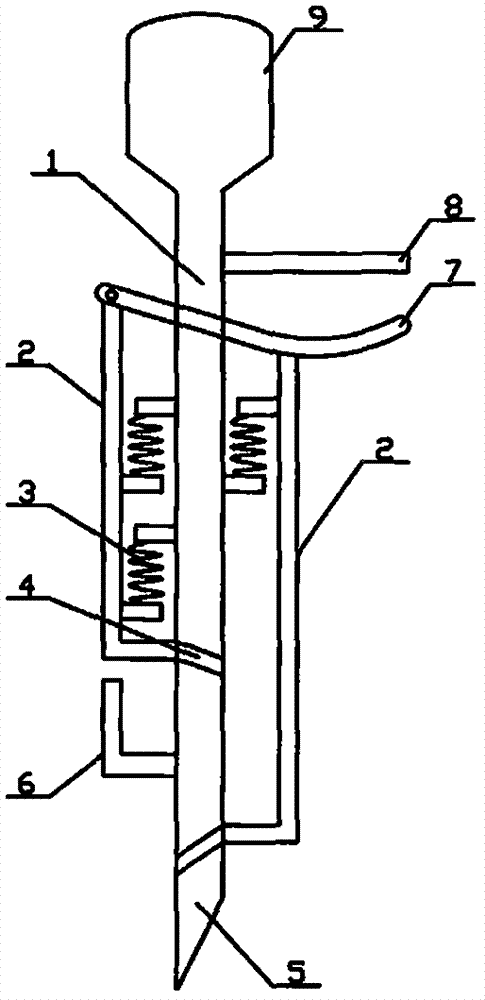

[0015] As shown in the figure, a fully automatic fertilizer applicator includes a hollow tube 1, a metal rod 2, a handle 7 and a feed funnel 9, the top of the hollow tube 1 is provided with a feed funnel 9, and the bottom of the hollow tube 1 is a discharge Port 5, the hollow tube 1 is provided with a handle 7 near the feeding funnel 9, the middle point of the handle 7 is connected to the rotating shaft between the hollow tube 1, and the end of the handle 7 on one side of the hollow tube 1 is connected and fixed with the metal rod 2 , the handle 7 on the other side of the hollow tube 1 is also connected and fixed with the metal rod 2, and the two metal rods 2 are fixed parallel to the hollow rod 1, and the two metal rods 2 and the handle 7 are connected by a rotating shaft. One end of the metal rod 2 not connected with the handle 7 is provided with a baffle 4, and two baffles 4 are arranged transversely and inserted into the side wall of the hollow tube 1, and the 4 sections of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com