Machining method for trapezoidal threaded hole chuck claw

A trapezoidal thread and processing method technology, applied in the field of mechanical processing, can solve the problem that the processing accuracy of the trapezoidal threaded hole chuck jaw cannot be guaranteed, and achieve the effects of improving the service life, improving the processing efficiency, and ensuring the processing accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

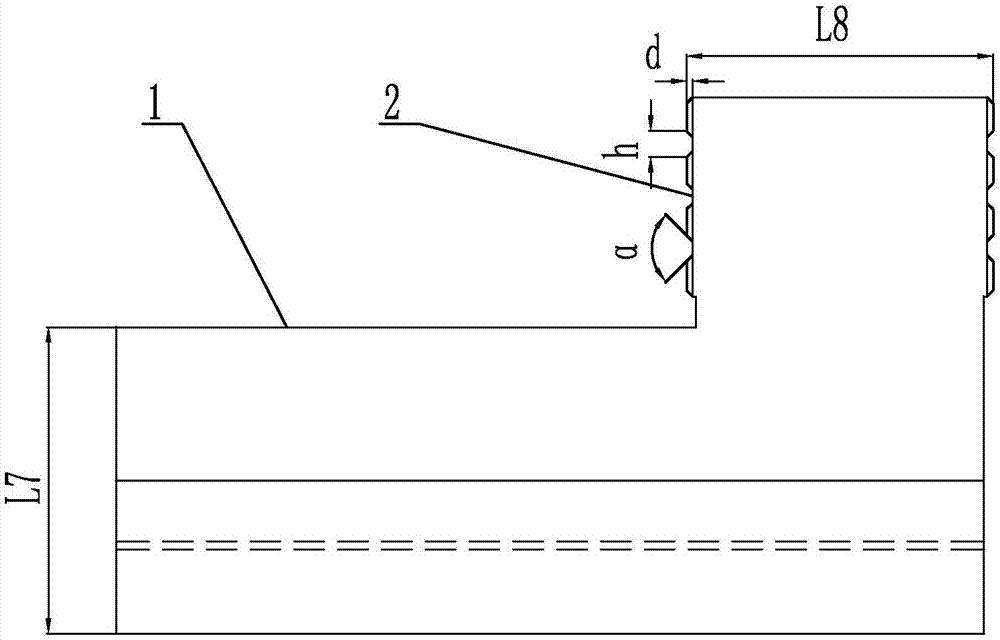

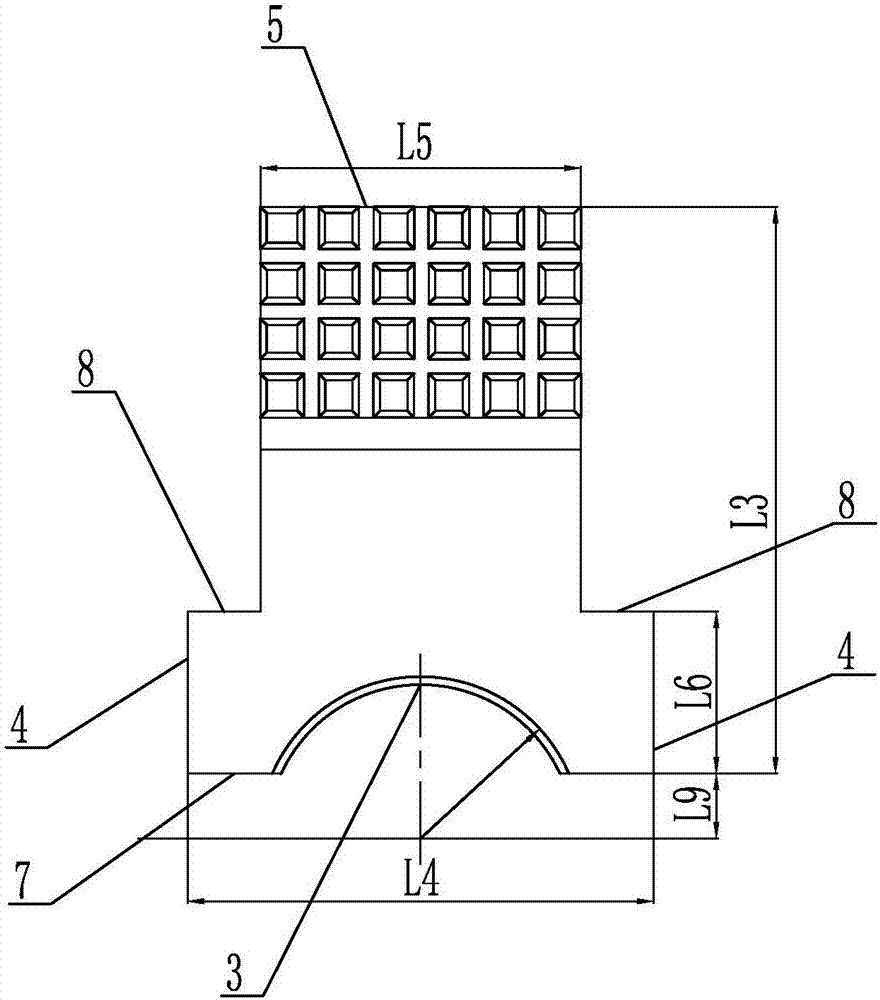

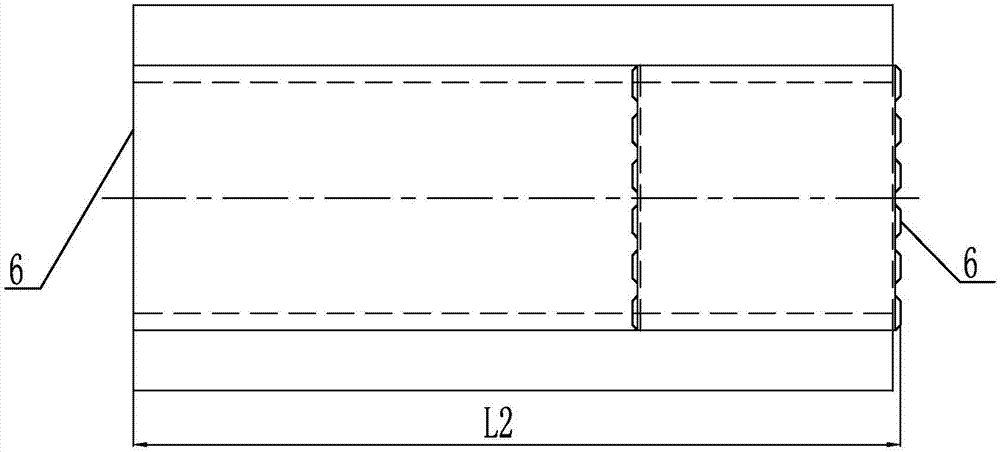

[0024] Specific implementation mode one: combine Figure 1 to Figure 4 To illustrate this embodiment, a trapezoidal threaded hole chuck jaw processing method described in this embodiment includes the following steps:

[0025] Step 1: Rough milling: Mill the raw material into a cuboid with a size of 290mm×144.7mm×400.7mm on a horizontal milling machine. The raw material can process two workpieces, milling the size of the stepped surface A1 to a height of 103mm, and milling the size of the stepped surface B2 to a width of 103mm;

[0026] Step 2: Rough drilling: the fitter first draws the axis of threaded hole 3, and then drills to φ55;

[0027] Step 3: Rough boring: boring threaded hole 3 to φ88 on CNC milling machine;

[0028] Step 4: heat treatment: heat treat the material until the Rockwell hardness is 31-35HRC;

[0029] Step 5: Grinding the end face D4: Grind the two end faces D4 separately on a surface grinder until the distance between the two end faces D4 is L4, the va...

specific Embodiment approach 2

[0043] Specific implementation mode two: combination Figure 1 to Figure 4 To illustrate this embodiment, the process of heat treatment in Step 4 of this embodiment is as follows: first heat the material in a medium-temperature furnace with a temperature range of 820-840°C for 30 minutes, and then put it into a water tank to cool to a temperature of 300-400°C , and then put it into an oil tank to cool to normal temperature, and finally put it into a tempering furnace with a temperature of 560°C and temper it for 2 hours. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0044] Specific implementation mode three: combination Figure 1 to Figure 4 To describe this embodiment, after the end face D4 is ground in Step 5 of this embodiment, the two end faces D4 are demagnetized. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com