Rope guiding machine with guiding rod type thread rope guiding device

The technology of a rope guide and a rope pressing device is applied in the field of rope guides, which can solve the problems of small lateral force, broken or pulled apart, and disorder of the wire rope, so as to achieve strong resistance to diagonal pulling and enhance diagonal pulling ability. , the effect of accurate transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

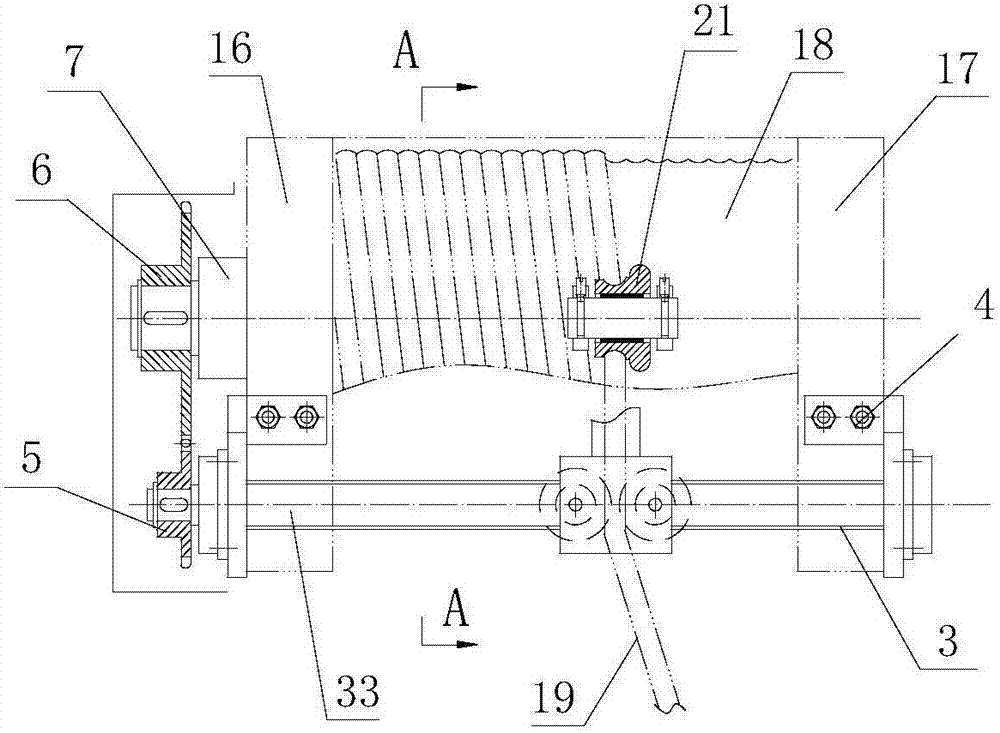

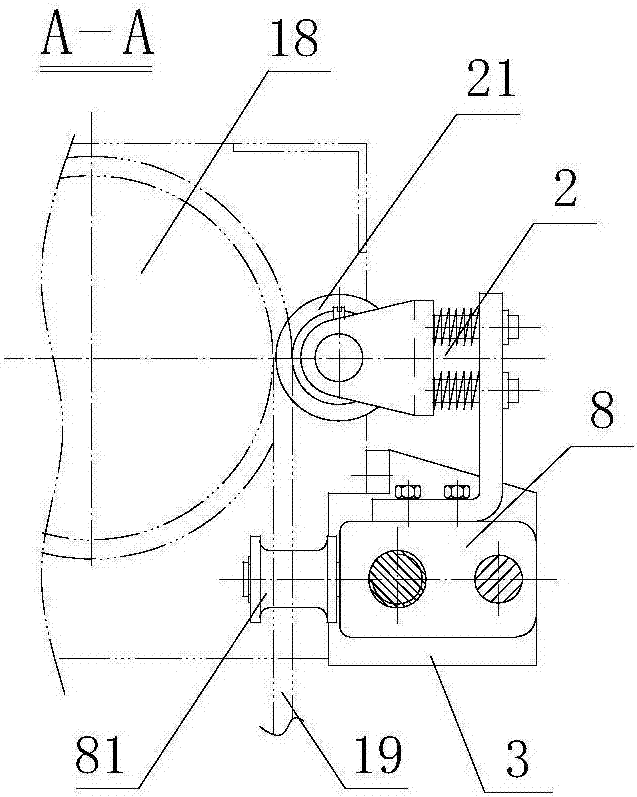

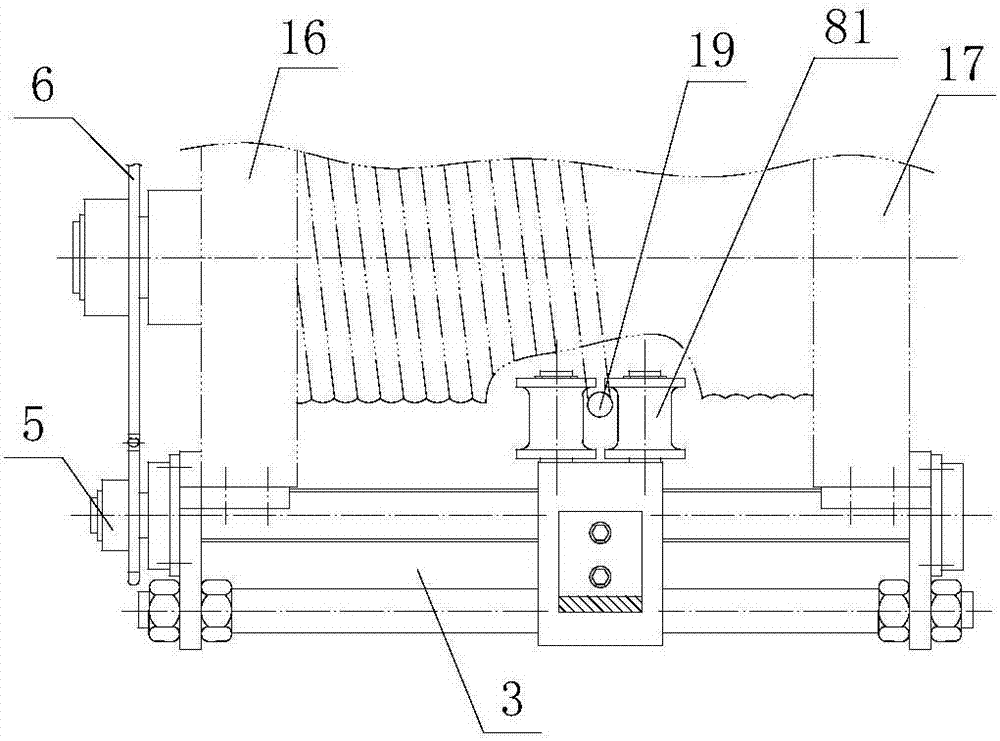

[0018] Such as figure 1 , figure 2 , image 3 As shown, a rope guide with a guide rod type thread guide device includes a guide rod type thread guide mechanism 3; the guide rod type thread guide mechanism 3 is connected to the front of the reel 18 through a bolt 4; the described The rope pressing wheel 21 in the guide rod type thread guide mechanism is pressed on the steel wire rope 19 of the last circle of the reel; the steel wire rope is connected to the hook group through the guide rope wheel 81; One end of the threaded shaft 33 is connected to the pinion 5; the pinion is meshed with the bull gear 6; the bull gear is connected to the joint shaft 7 through a flat key; the joint shaft is connected to one end of the reel shaft of the electric hoist with a screw , and the two are connected by a coaxial cable.

[0019] Such as Figure 4 As shown, the guide rod type threaded guide mechanism 3 includes a threaded shaft 33, a rope guide device 8, a rope pressing device 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com