Co-extrusion plastic wood internal wall panel

An interior wall panel, co-extrusion technology, applied in building materials, building components, buildings, etc., can solve the problems of cracking, weak fixation, insufficient strength of plastic-wood interior wall panels, etc., to achieve stable installation, prolong service life, Guaranteed installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

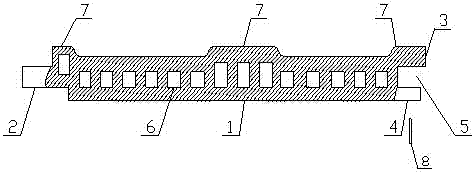

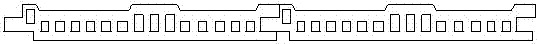

[0020] see figure 1 and 2 , the embodiment of the present invention discloses a co-extruded plastic-wood interior wall panel, which includes a main wall panel 1, and the main wall panel 1 is a rectangular plate-shaped structure. The middle part of one side (left side) of the main wallboard 1 protrudes outwards (towards the left) to form a tenon 2, and the upper and lower sides of the other side (right side) of the main wallboard 1 respectively extend outwards (towards the right) to form an upper wing 3 And the lower wing plate 4, the upper wing plate 3 and the lower wing plate 4 form a groove 5 matched with the tenon 2, and the tenon 2 is arranged opposite to the groove 5. The main wallboard 1 is provided with a through hole 6 along its length direction. The af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com