Building decoration lamp

A technology for decorative lights and buildings, applied in the field of building decorative lights, can solve the problems of increasing material and labor input, not suitable for SMD light strips, and difficult production, and achieve material and labor saving, simple structure and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

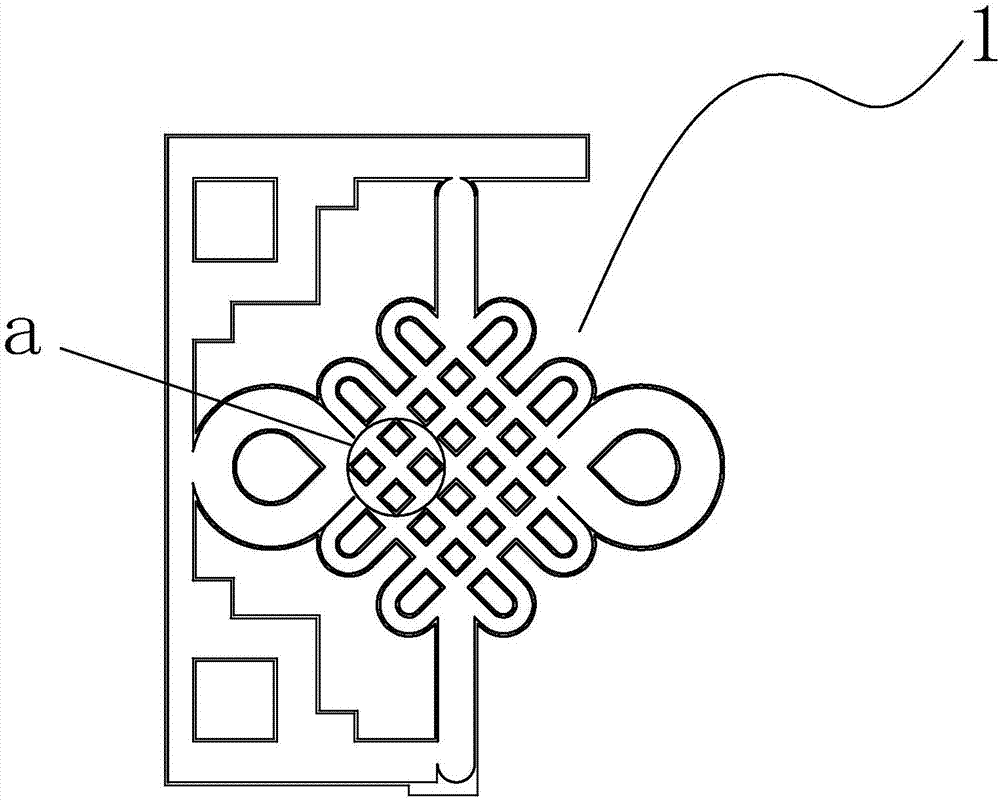

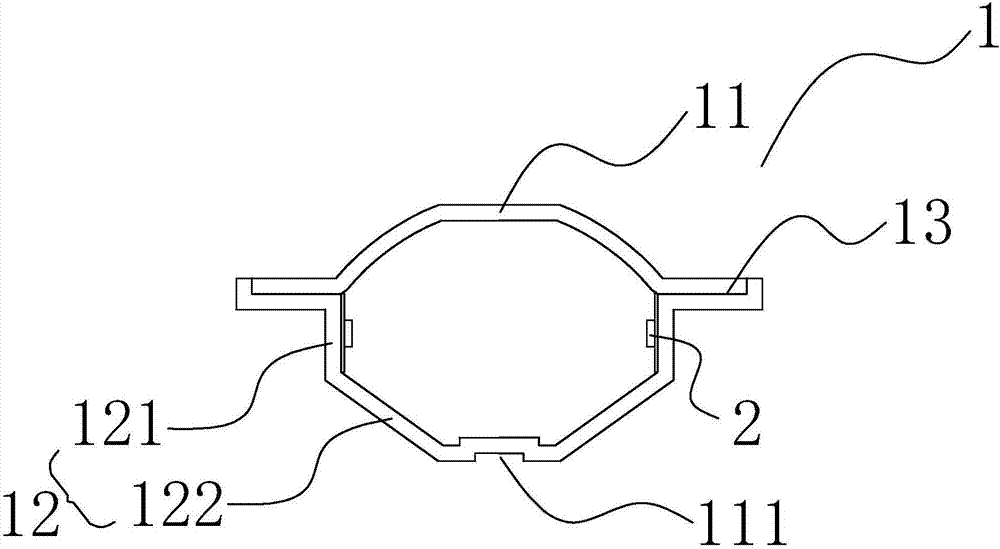

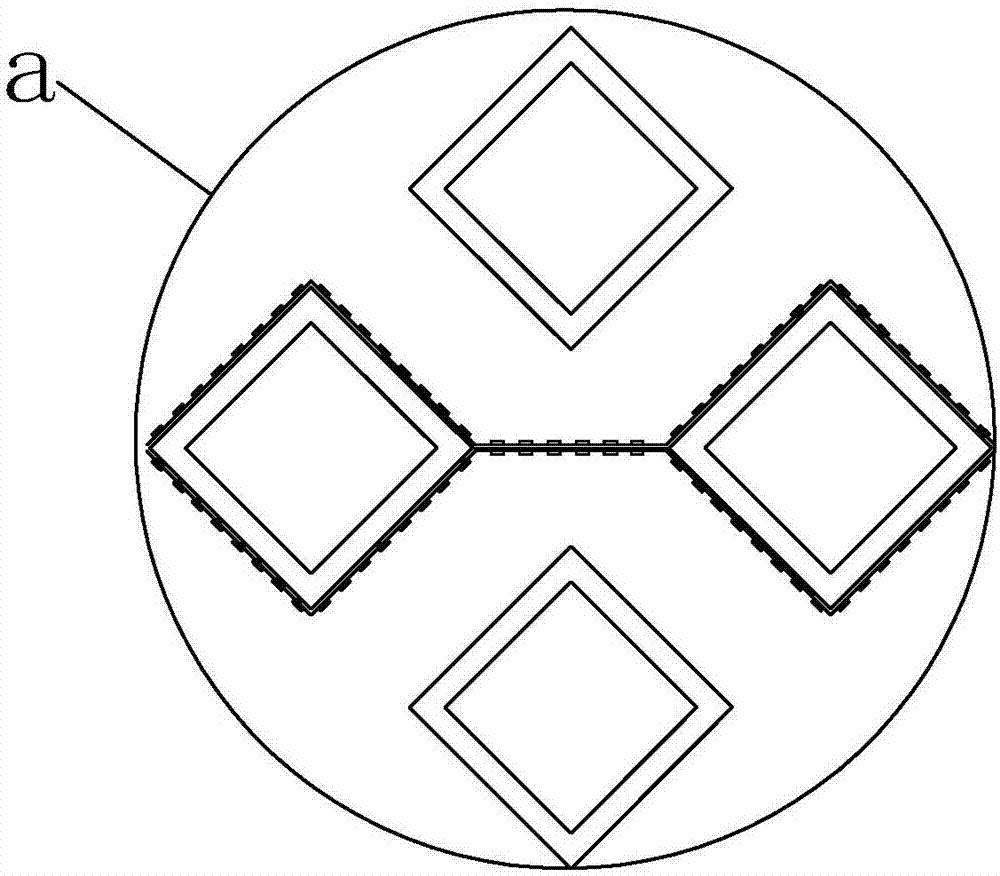

[0017] First example: please refer to figure 1 , figure 2 and image 3 , which shows a building decorative lamp of the present invention, including a light-transmitting profiled plastic lamp body shell 1, a patch lamp strip 2 and connecting wires, and the lamp body shell 1 includes a front viewing surface 11 and a side surface 12. The inner wall of the side surface 12 of the lamp body shell 1 has a patch lamp strip 2 pasted on it. Generally, the opposite front and rear sides of the LED Chinese knot lamp are set as the positive viewing surface 11, so that the viewing surface of the lamp is more Wider, better use effect, stronger decoration. Compared with other kinds of LED lights, SMD light strip 2 has a large luminous angle, high brightness, low light decay, can be curled, cut and extended, hard texture, good insulation and waterproof performance, strong weather resistance, long service life, easy to use The advantages of making graphics, text and other shapes, the applica...

no. 2 example

[0024] The second embodiment: please refer to Figure 4 , on the basis of the first embodiment, the sticking surface 121 is provided with two or more steps in different height differences. In this embodiment, the sticking surface 121 is set in three steps, so that the lamp body The shell 1 has a richer shape and a more three-dimensional effect.

no. 3 example

[0025] The third embodiment: please refer to Figure 5 , on the basis of the first embodiment, the sticking surface 121 is provided with five steps, and the lamp body shell 1 is provided with a second layer of plastic shell 3 for changing the lighting effect, and the second layer of plastic shell 3 is clipped or plugged in. Installed inside the lamp body shell 1, the SMD light strip 2 is then installed on the second layer of plastic shell 3, the SMD light strips 2 on different steps are connected by connecting wires, the second layer of plastic shell 3 can use different colors, It is also possible to set some through holes with different patterns, so that the light has various colors with distinct levels, thereby producing different lighting effects, increasing the expressive force of the light, and improving the aesthetics of the lamp.

[0026] To sum up, the lamp body packaging structure of the present invention has the following advantages: the patch lamp strip 2 is directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com