Beef automatic stir-frying pot

An automatic turning and beef technology, which is applied to the lids, inserts, cooking utensils and other directions of cooking utensils, can solve the problems of unbalanced stirring of food, lack of limit devices, high labor intensity, etc. The effect of uniform and improved work efficiency

Inactive Publication Date: 2018-01-09

习水县黔道食品科技有限公司

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For chefs who need to fry a large amount of food at one time, such as canteens, restaurants, and enterprises, operating with a shovel at high temperature for a long time is not only labor-intensive, but also causes food quality such as burnt burns due to untimely stir-frying. question

In view of this, many automatic stir frying pots have been produced in the market. They usually install a motor on the machine base, and then let the shovel stir the food in the pot through gear transmission, and there is a lack of necessary communication between the shovel and the pot body. The limit device causes the relative deflection of the position of the shovel and the pot body when the motor rotates, so that the food cannot be stir-fried in a balanced manner, and local burnt phenomenon occurs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

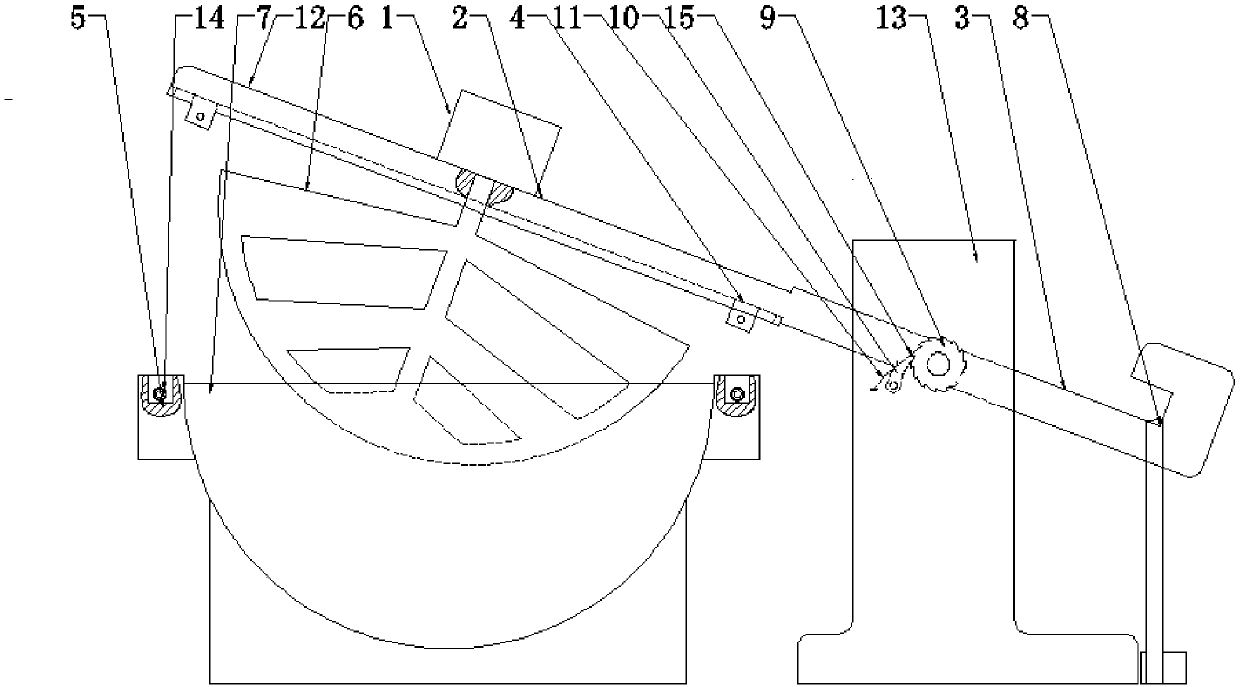

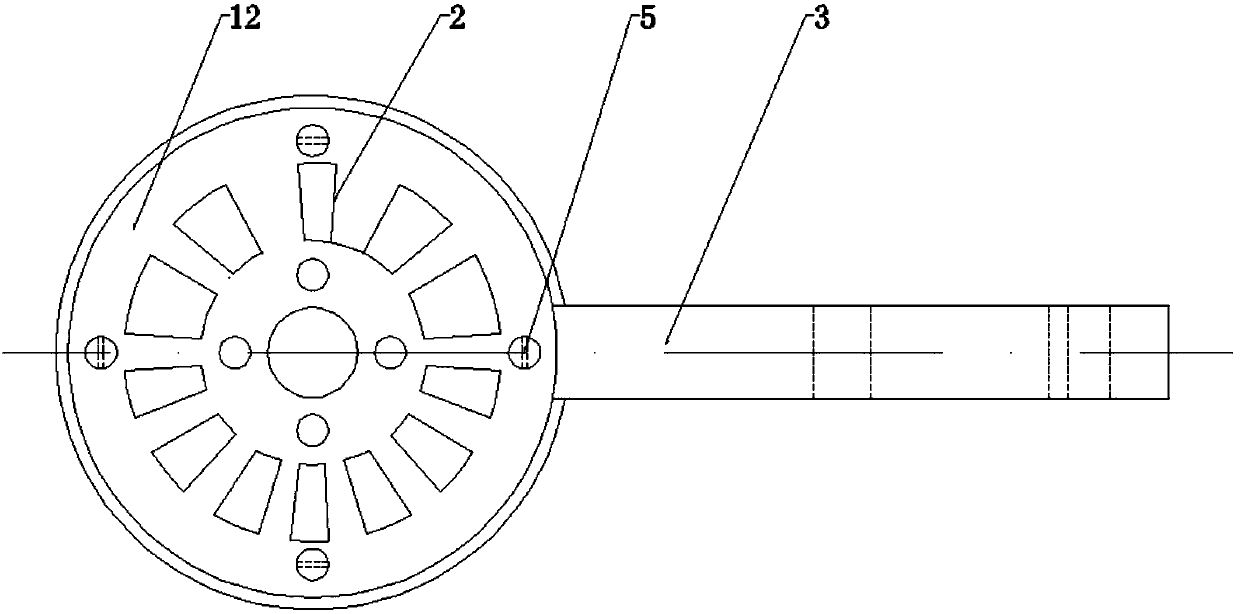

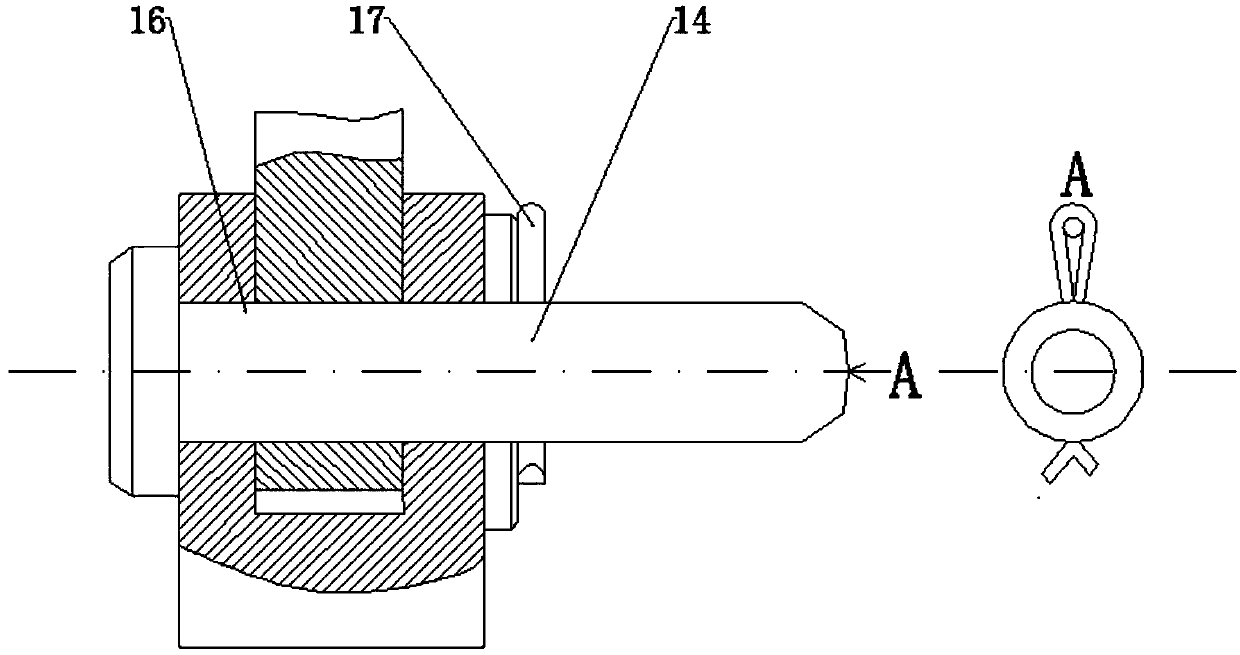

The invention belongs to the technical field of food processing machinery and equipment, and particularly relates to a beef automatic stir-frying pot which comprises a pot body, a pot cover, a motor seat, a motor and a pot turner, multiple limiting grooves in uniform distribution are welded on the outer side of the pot body, the pot cover comprises a pot cover body and a pot cover rod, a limitingblock matched with the limiting grooves is arranged on the inner side of the pot cover body, the pot cover rod is fixed at one end of the pot cover body and connected on the motor seat, the motor is mounted exactly in the middle of the pot cover body, a rotating shaft of the motor is downward, and the iron shovel is mounted on the rotating shaft of the motor. The beef automatic stir-frying pot hasthe advantages that through cooperation of the limiting grooves and the limiting blocks, the pot cover and the pot body are connected into a whole, in this way, the problem that the iron turner deflects in position relative to the pot body due to rotating of the motor is solved, so that the iron turner is enabled to perform stir-frying according to a set route, and food stir-frying quality is improved.

Description

technical field [0001] The invention belongs to the technical field of food processing machinery and equipment, in particular to an automatic beef frying pan. Background technique [0002] Frying pan is an indispensable equipment in people's daily life. For chefs in canteens, restaurants, enterprises, etc. who need to fry a large amount of food at one time, operating with a shovel at high temperature for a long time is not only labor-intensive, but also causes food quality such as burnt burnt due to untimely stir-frying. question. In view of this, many automatic stir frying pans have been produced in the market. They usually install a motor on the machine base, and then allow the shovel to stir fry the food in the pot through gear transmission, and there is a lack of necessary communication between the shovel and the pot body. The limit device causes the relative deflection of the position of the shovel and the pot body when the motor rotates, so that the food cannot be st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47J27/14A47J27/00A47J36/06A47J36/16

Inventor 杨泽

Owner 习水县黔道食品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com