Novel smokeless electric oven

An electric oven, a new type of technology, applied in the direction of roaster/barbecue grid, kitchen utensils, household utensils, etc., can solve the problems of high production cost and use cost, large cost investment, environmental impact, etc., to achieve low manufacturing cost, Low cost and reduced oil loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

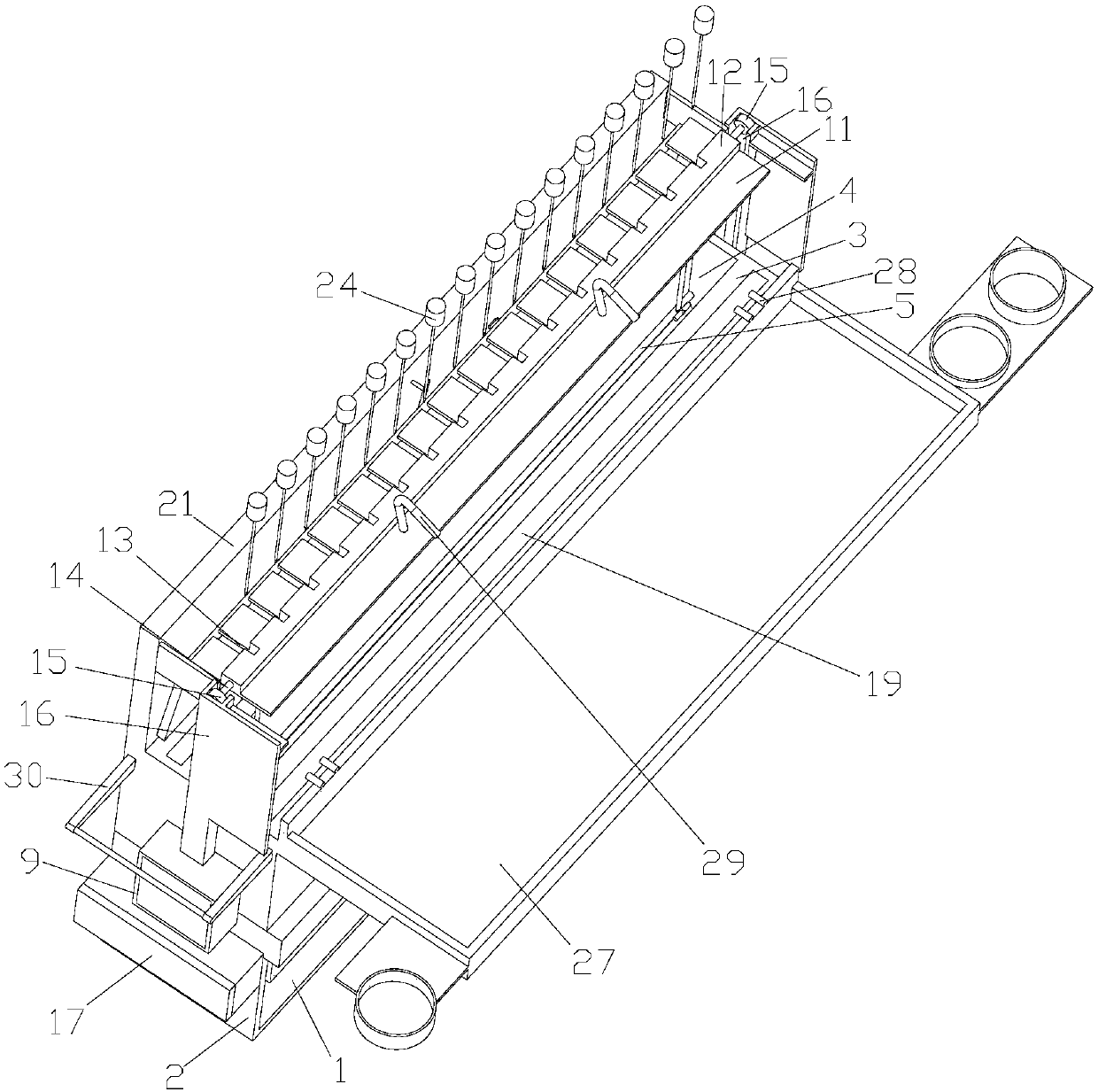

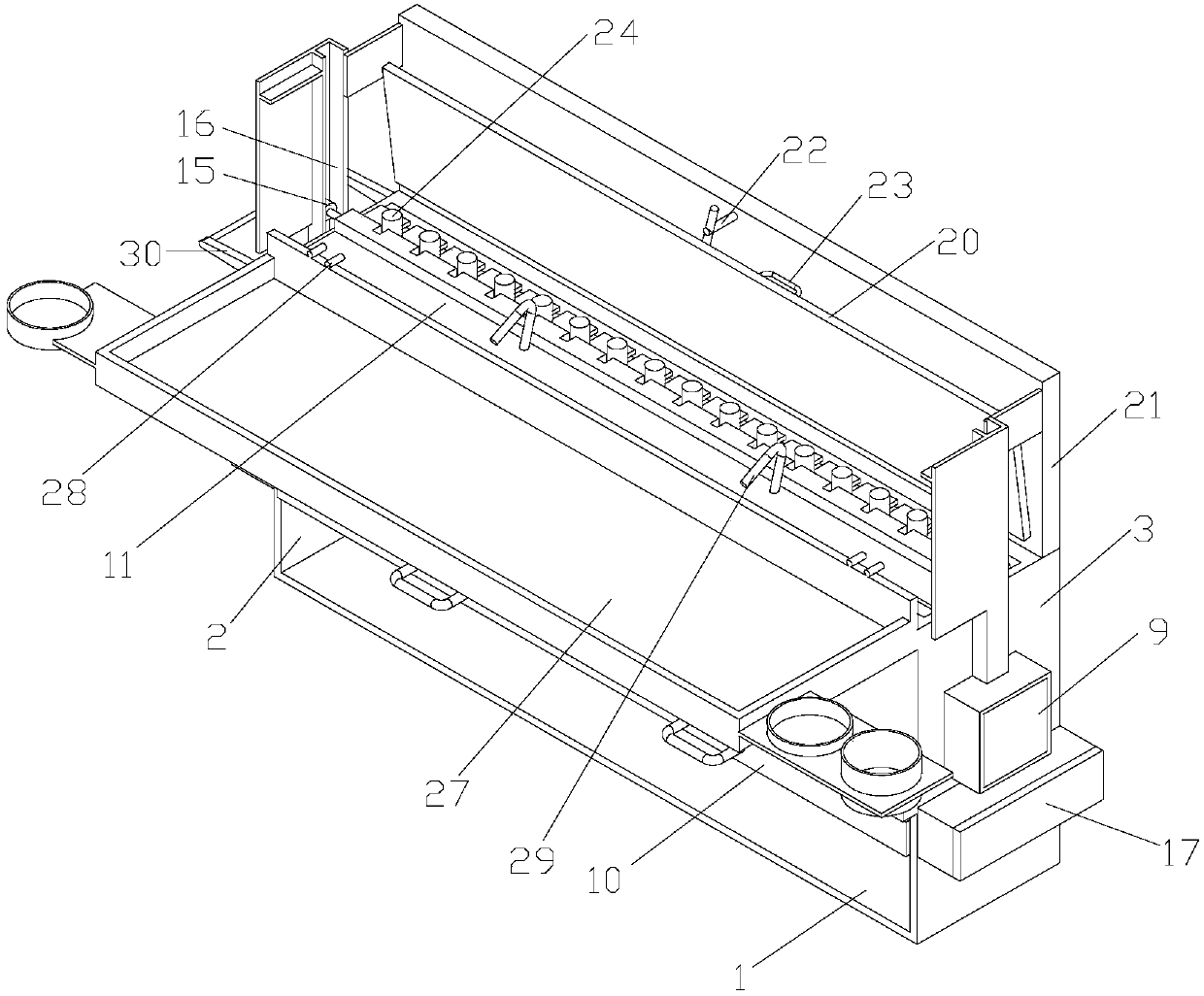

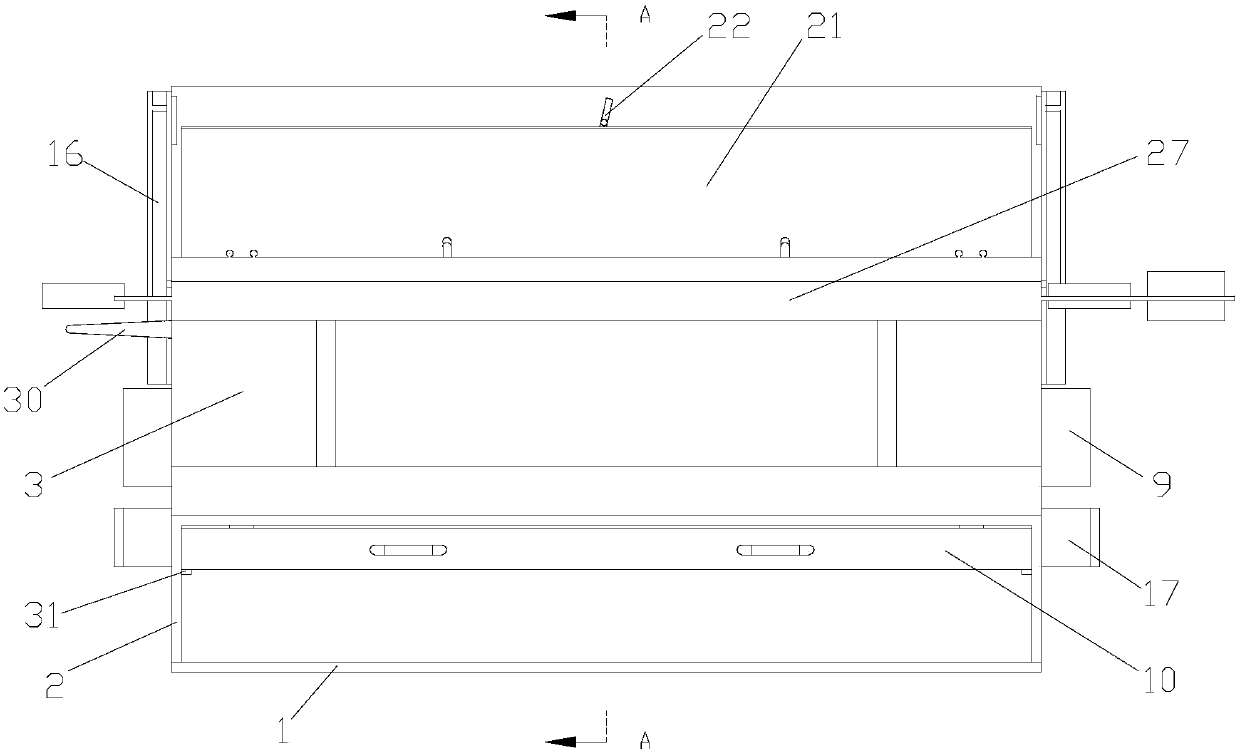

[0039] In this embodiment, a new smokeless electric oven includes a bottom plate 1. As the best implementation mode of this embodiment, the above-mentioned bottom plate 1 is a rectangular plate. The left and right ends of the upper surface of the above-mentioned bottom plate 1 are respectively provided with supports Plate 2, a furnace body 3 is lapped between the support plates 2 at the left and right ends of the bottom plate 1, and the function of the support plate 2 is to vacate the furnace body 3. As another implementation of this embodiment, a bracket may be provided on the lower surface of the furnace body 3 , as long as the furnace body can be vacated.

[0040] In this embodiment, the furnace body is in the shape of a cuboid, and its left end is lapped on the upper surface of the support plate 2 installed on the left end of the bottom plate 1, and its right end is lapped on the upper surface of the support plate 2 installed on the right end of the bottom plate 1. The fur...

Embodiment 2

[0046] This embodiment is further improved on the basis of Embodiment 1. As shown, in this embodiment, the number of the above-mentioned heating tubes 5 is limited to more than one. Several protrusions 8 are arranged side by side on the inner side wall of the above-mentioned barbecue chamber 4. As the best implementation mode of this embodiment, the above-mentioned protrusions 8 are arranged on the front and rear side walls of the above-mentioned barbecue chamber 4, and the above-mentioned protrusions 8 is a strip structure with a triangular cross section. In this embodiment, in order to make the heat generated by the heating tube 5 more concentrated in the above-mentioned barbecue chamber 4, a heating tube 5 is arranged between every two adjacent protrusions 8, so that the heating tube 5 radiates The heat emitted will be reflected and concentrated on the slope of the above-mentioned protrusion 8. The above-mentioned design can not only improve the heating efficiency during th...

Embodiment 3

[0048] This embodiment is further defined and improved on the basis of the above-mentioned embodiments. In this embodiment, the above-mentioned heating tube 5 is limited to be an electric heating tube in order to improve its controllability. Of course, the above-mentioned heating tube 5 can also be any other heating tube. source. The electrode terminals of the heating pipe 5 are located at the left and right ends of the above-mentioned heating pipe 5. When it is specifically installed, the above-mentioned electrode terminals are placed outside the above-mentioned barbecue chamber 4, and the left end electrode terminals of the plurality of heating pipes 5 and the plurality of hairs The right end electrode terminals of the heat pipes 5 are respectively connected in series. With the above-mentioned structure, in the case of electrification, several above-mentioned heat pipes 5 will generate heat at the same time, so that when grilling, the heat pipes 5 can heat the food. It is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com