Automatic coiling device for external evaporator cooling tube of refrigeration liner

A technology of refrigeration tubes and evaporators, applied in auxiliary devices, manufacturing tools, and other manufacturing equipment/tools, etc., can solve the problems of affecting the cooling effect of the inner tank of the water dispenser, the welding effect cannot be guaranteed, and the bonding degree is not good enough, etc., to achieve Better cooling effect, simple structure and good fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

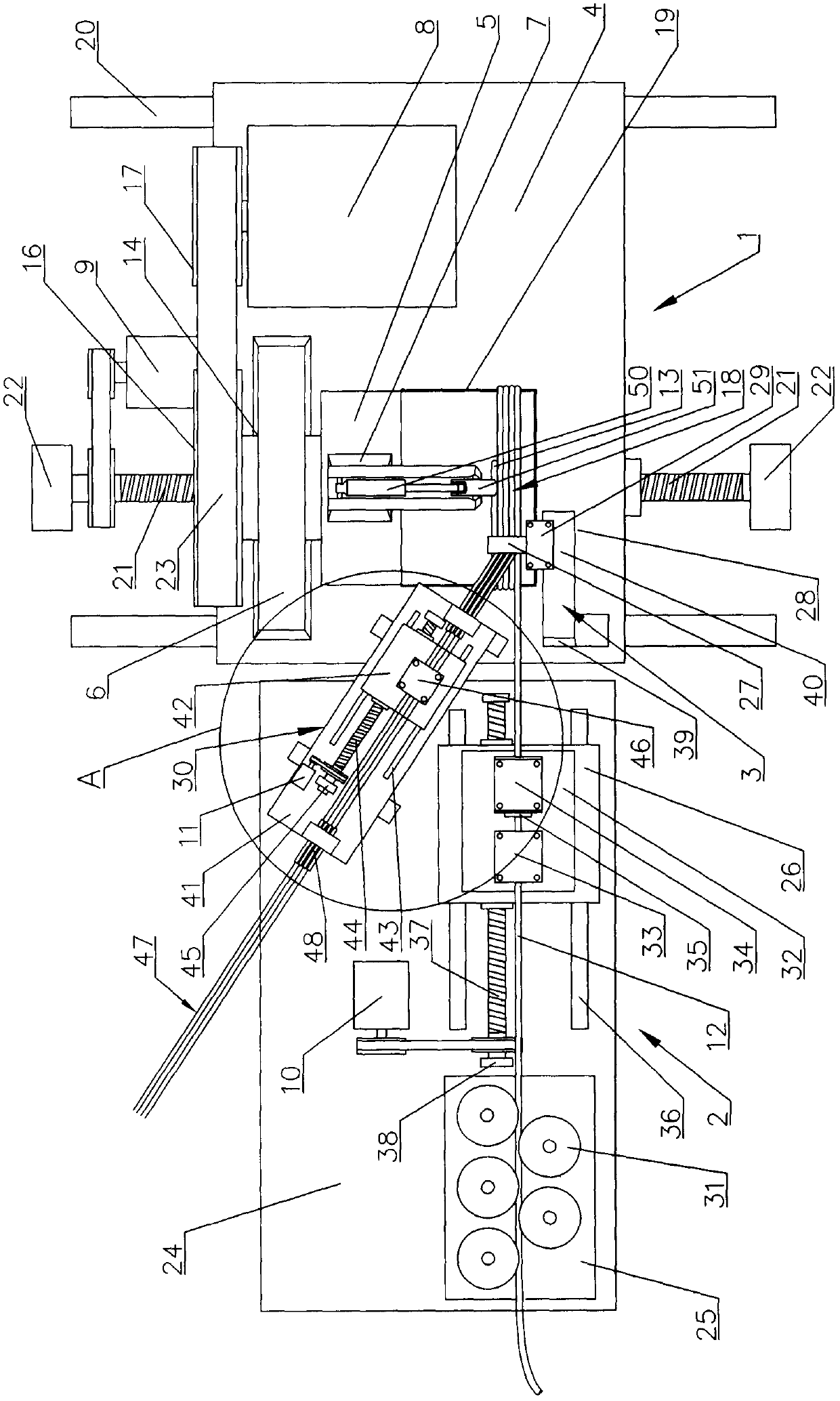

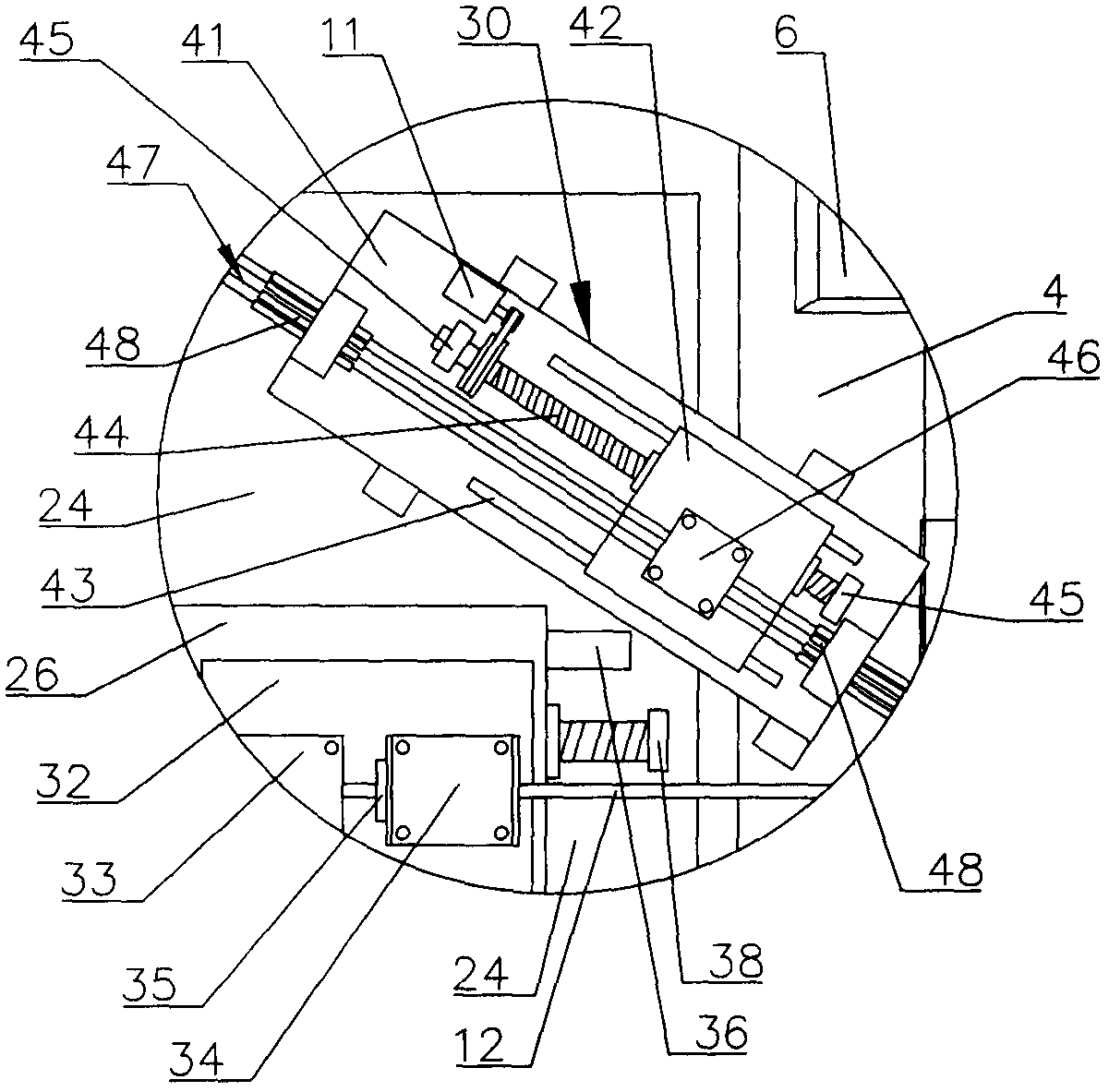

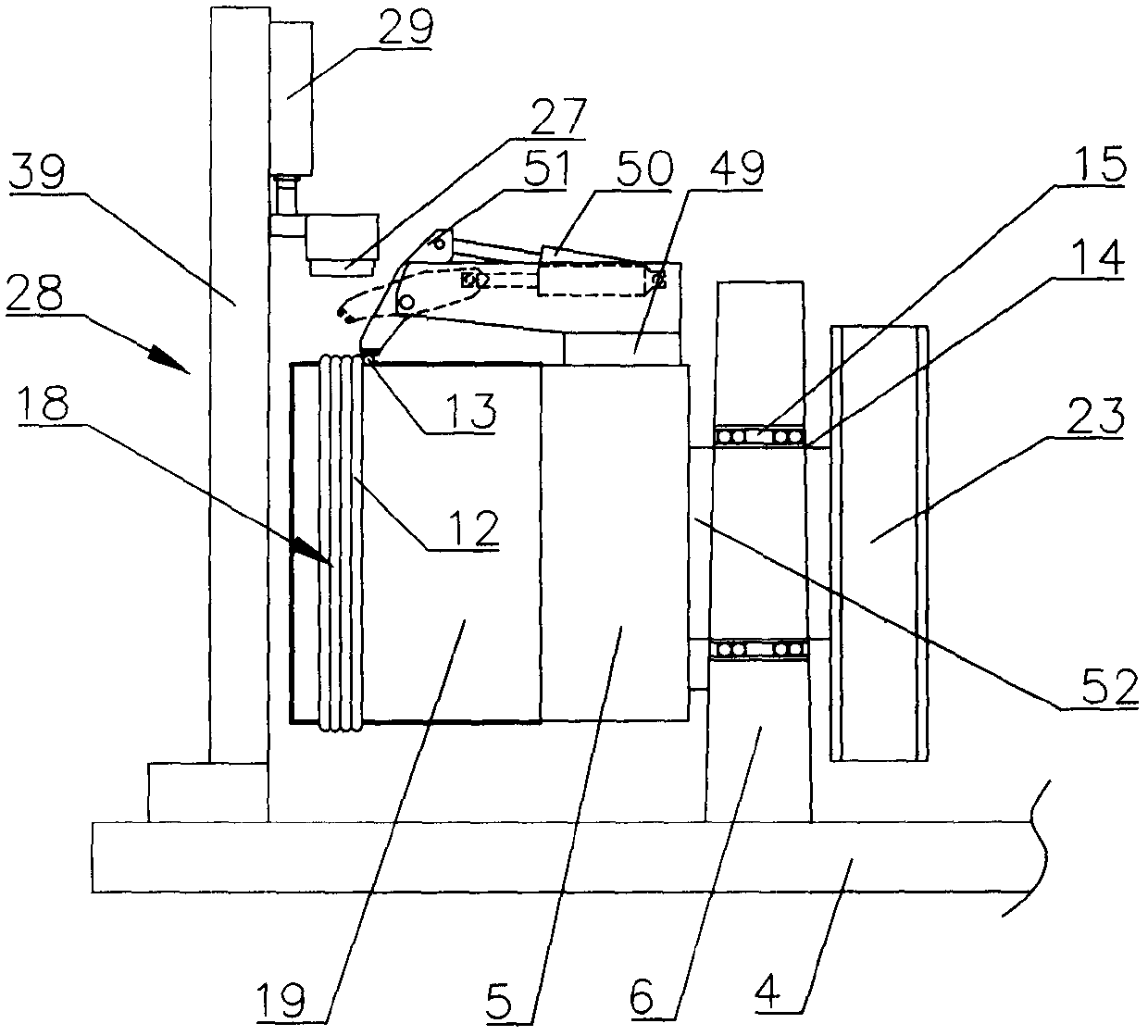

[0022] Depend on Figure 1-Figure 3 As shown, the present invention discloses an automatic coil device for refrigerating tubes of a refrigerating inner tank and outer evaporator, including a controller (not shown), an inner tank fixture device 1, a cooling tube feeding device 2, and a welding platform 3; The clamp device 1 includes a clamp platform 4 and an inner tank fixing sleeve 5 fixed on the clamp platform 4, an inner tank fixing sleeve base 6, a tube pressing device 7, a first motor 8 and a second motor 9; the controller and the first The motor 8 and the second motor 9 are electrically connected (not shown); the pressure tube device 7 is arranged on the top surface of the inner tank fixing sleeve 5, and is used to compress t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com