Yarn impurity removal device in the warp guide device of warp knitting machine

A warp knitting machine and yarn technology, used in warp knitting, textiles, papermaking, knitting, etc., can solve the problem of yarn intermingling, affecting the normal knitting, etc., and achieve the effect of reducing the probability of breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

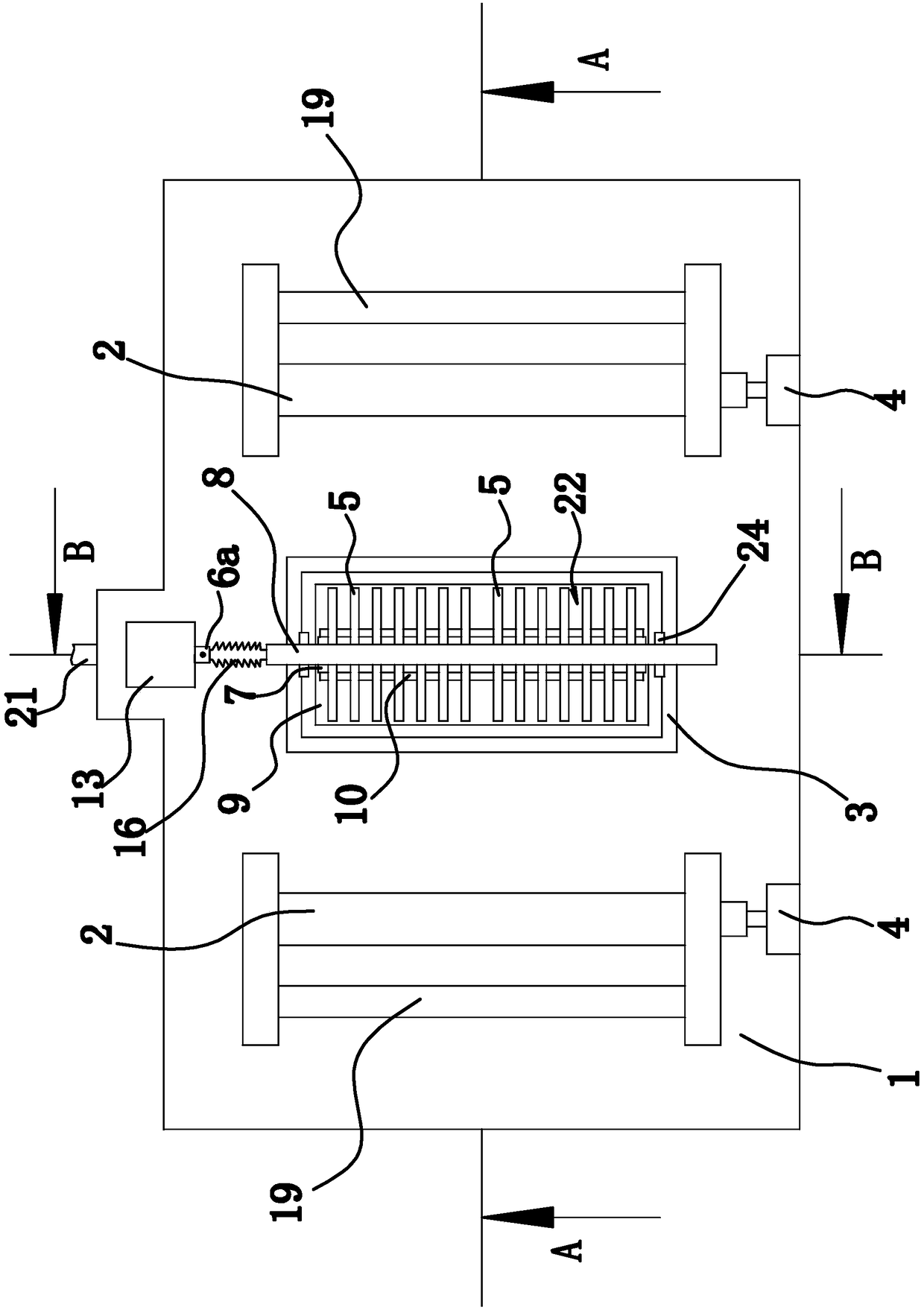

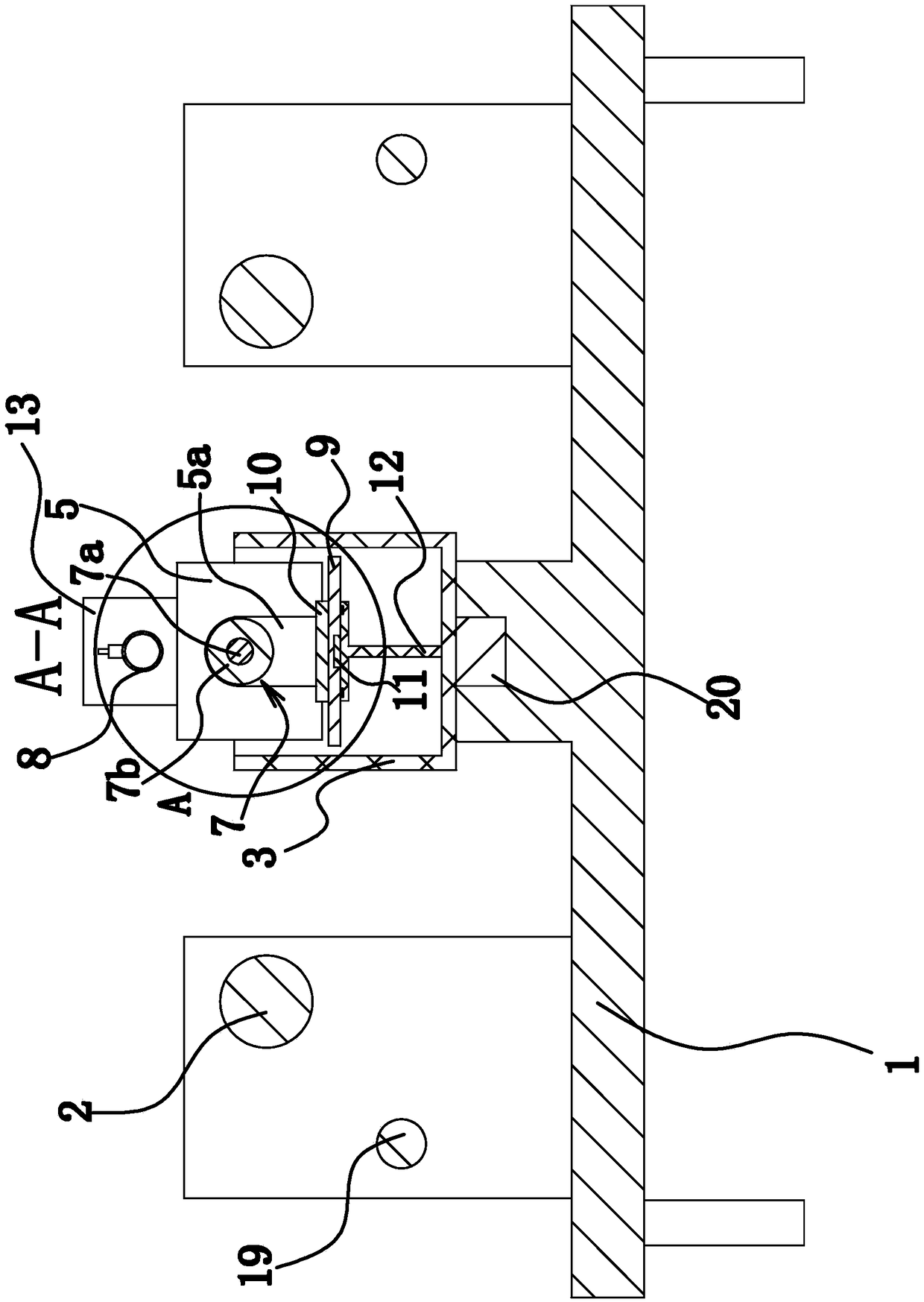

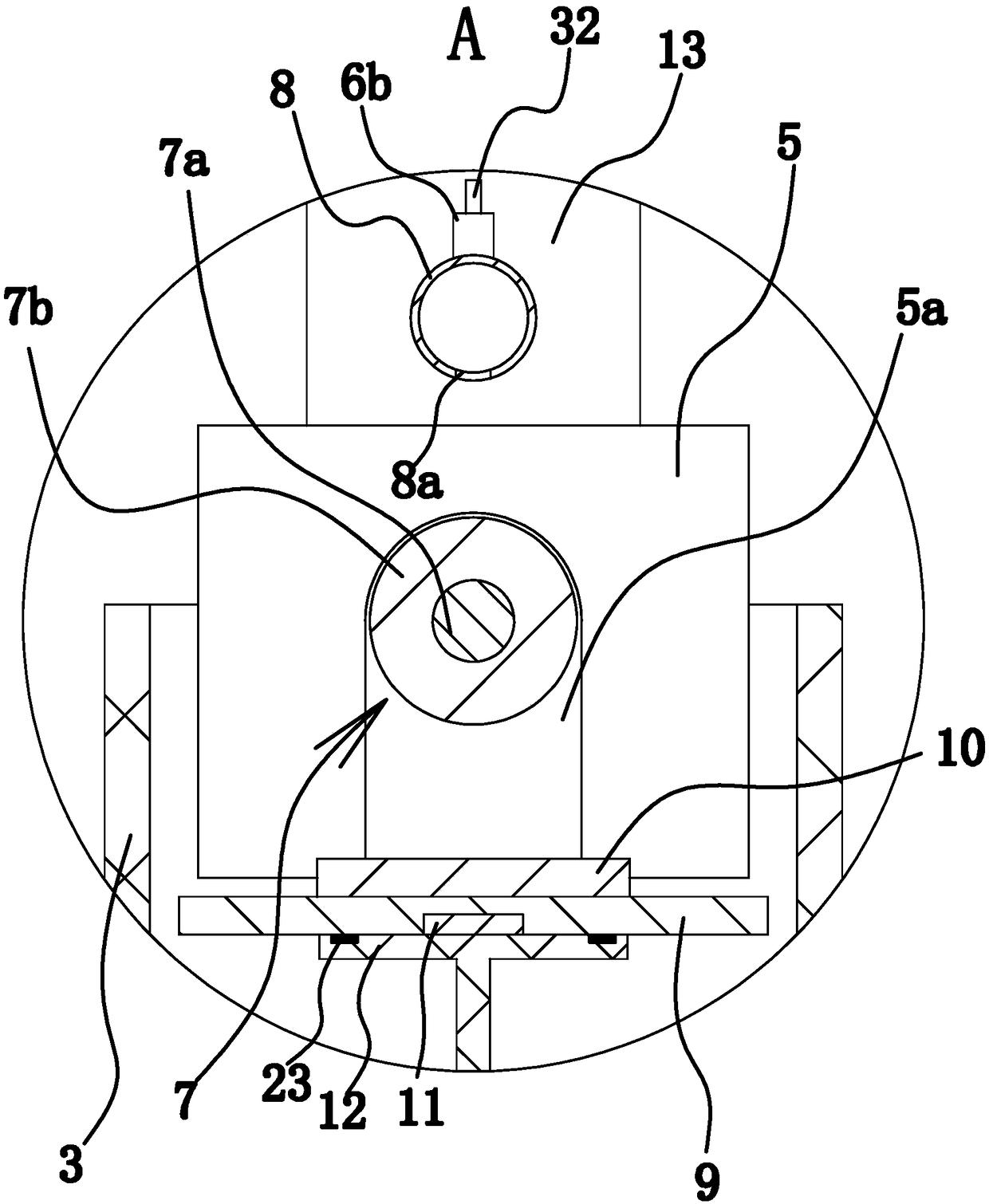

[0030] Such as Figure 1 to Figure 7 As shown, the warp-knitting machine warp guiding device is composed of frame 1, wire feeding roller 2, groove body 3, motor 4, partition plate 5, blower fan 6, lubricating shaft 7, air pipe 8, support plate 9, mounting plate 10, magnetic Block 11, support 12, silencer box 13, spring one 14, spring two 15, stainless steel bellows 16, regulating pipe 17, connecting column 18 etc. are formed.

[0031] Wherein, the wire feeding roller 2 is arranged on the frame 1 along the horizontal direction, and there are two wire feeding rollers 2 arranged side by side. exist figure 1 Among them, the axes of the wire feeding rollers 2 are arranged along the front and rear directions, and the two wire feeding rollers 2 are distributed along the left and right directions. Both wire feeding rollers 2 are rotatably connected with the frame 1, so that the wire feeding rollers 2 can rotate around their own axes. The front sides of the two wire feeding rollers ...

Embodiment 2

[0056] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that the detachable locking mechanism includes a second bolt hole that runs through the side wall of the adjustment tube 17, and a bolt that is set on the side wall of the connecting column 18. Hole 3 and bolt 2 are screwed in bolt hole 2. There are multiple bolt holes 3 and are distributed along the axial direction of connecting column 18. The end of bolt 2 is screwed in one of bolt hole 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com