Special fiber drying machine

A special fiber and drying machine technology, which is applied in the direction of local stirring dryers, static material dryers, dryers, etc., can solve the problems of poor drying effect and achieve the effect of improving drying efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

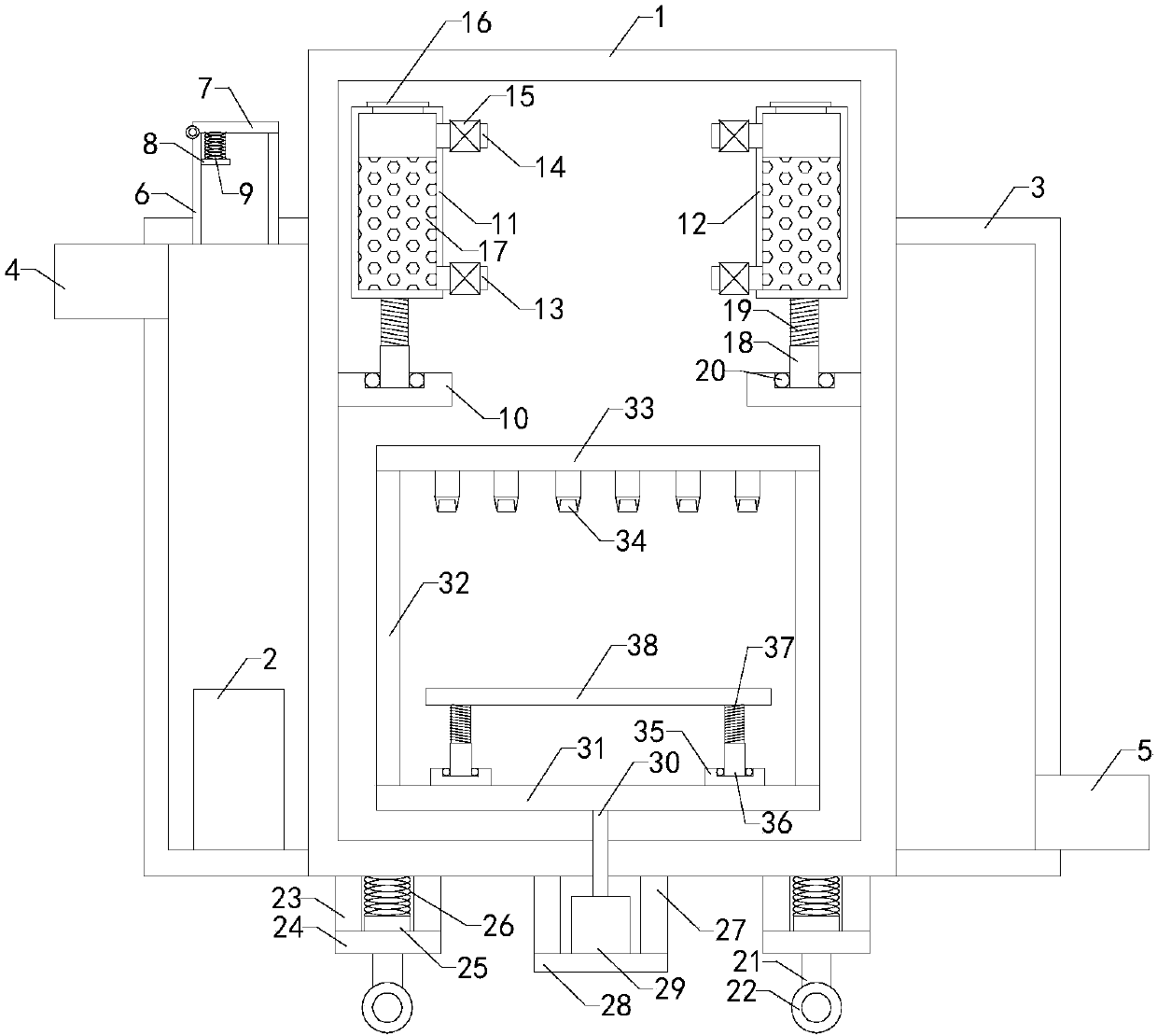

[0014] Such as figure 1 As shown, the special fiber dryer of the present invention includes a main body 1, a placement rack and an electric heater 2, a placement cavity is provided inside the main body, a pick-and-place opening is provided on the front side of the main body, and a pick-and-place opening is provided at the pick-and-place mouth. The door is blocked, and the placement frame is located in the placement chamber; it also includes a jacket 3, the jacket is installed on the outer wall of the main body, a heating chamber is formed between the jacket and the main body, the electric heater is located in the heating chamber, and the outer wall of the jacket is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com