Permanent magnet synchronous motor

A technology of permanent magnet synchronous motors and permanent magnets, applied in synchronous machines, synchronous machine parts, electrical components, etc., can solve the problems of mechanical deformation of magnetic paths, magnetic flux leakage, and low utilization rate of permanent magnet materials, and achieve reliable structure, Avoid the effects of mechanical deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

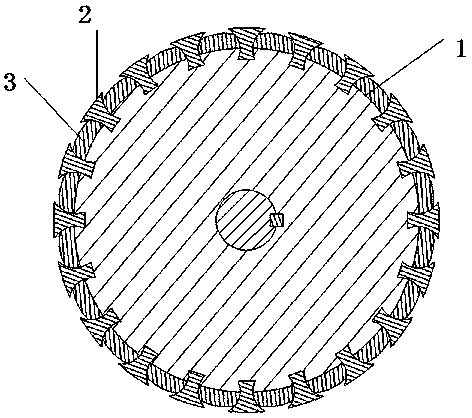

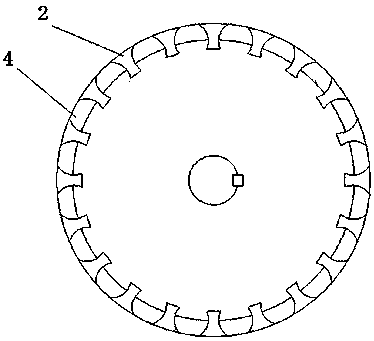

[0011] Embodiments are described in detail in conjunction with the accompanying drawings,

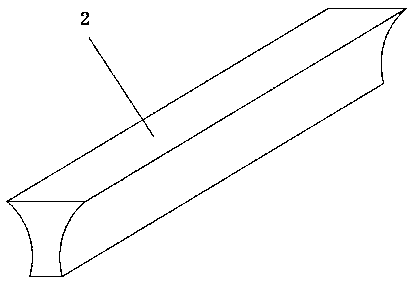

[0012] A permanent magnet synchronous motor, which includes a rotor core 1, and a special-shaped cage bar 2 is arranged on the outer side of the rotor core along the rotor axial direction, and the bottom corner of the centripetal part of the special-shaped cage bar is stuck on the silicon steel sheet on the rotor core In the slot corresponding to the shape, the two ends of the special-shaped cage are fixedly connected with the end ring 4, and the permanent magnet 3 is inlaid between the special-shaped cage, and the magnetic properties of the permanent magnets between adjacent two poles are opposite. The polarities of the permanent magnets between the special-shaped bars are the same; the section of the special-shaped cage bars described in this embodiment is a hyperbola.

[0013] The magnetization direction of each permanent magnet stuck in the adjacent cage of the opposite sex is chamf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com