Hydro jets for pitch ball replacement nozzles

A technology of hydraulic injector and nozzle, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of severe nozzle erosion, increase the difficulty of construction, deformation of internal flow channel, etc., and achieve good sealing effect , cost saving, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

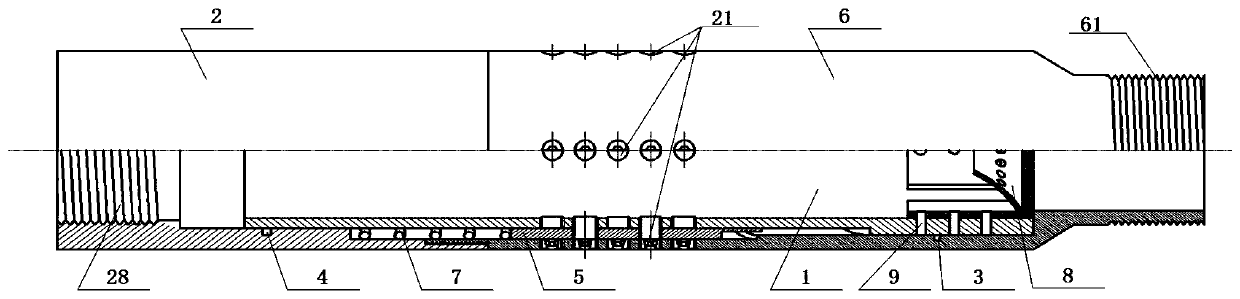

[0037] exist figure 1 In the shown schematic diagram of the water power injector for replacing the nozzle with a ball, the outer cylinder with a cavity is set outside the inner cylinder 1 with a cavity, and the elastic ball seat 8 is set in the inner cylinder through a pin 9 and is fixedly connected with the inner cylinder, as shown in Figure 10 As shown, the large end of the horn plate 81 with cracks in the elastic ball seat is fixed with a fixed plate 83 extending along the direction of the small end of the horn plate and can be fixed with the inner cylinder by pins. The fixed plate 83 is provided with several The through holes of the fixed plate are transparent, and the speaker plate 81 is provided with a plurality of transparent through holes 82 at intervals.

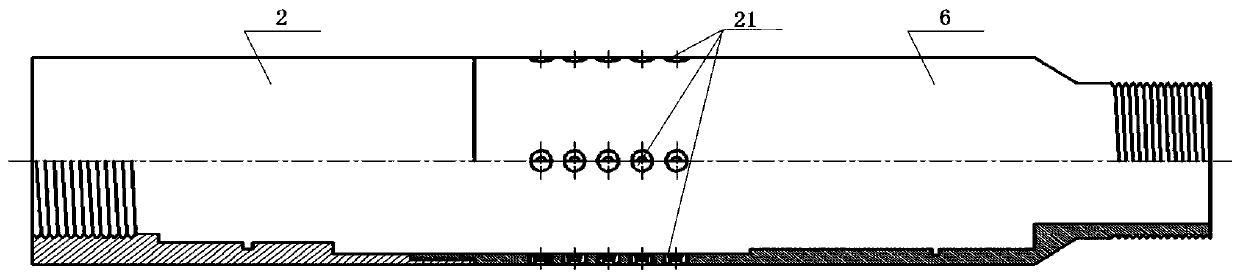

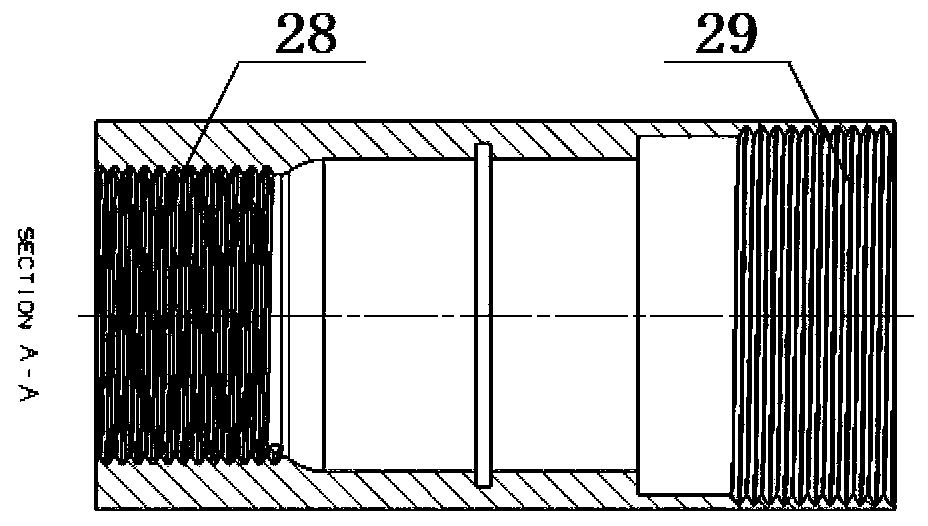

[0038] Such as figure 2 As shown, the second outer cylinder 6 in the outer cylinder is threadedly connected with the first outer cylinder 2; image 3 As shown, one end of the first outer cylinder is a female joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com