Wide-view surface defect detector

A defect detection, wide field of view technology, applied in the direction of optical testing flaws/defects, can solve the problems of low efficiency, small field of view, long inspection time, etc., to avoid defects, improve work efficiency, and easy to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings and embodiments.

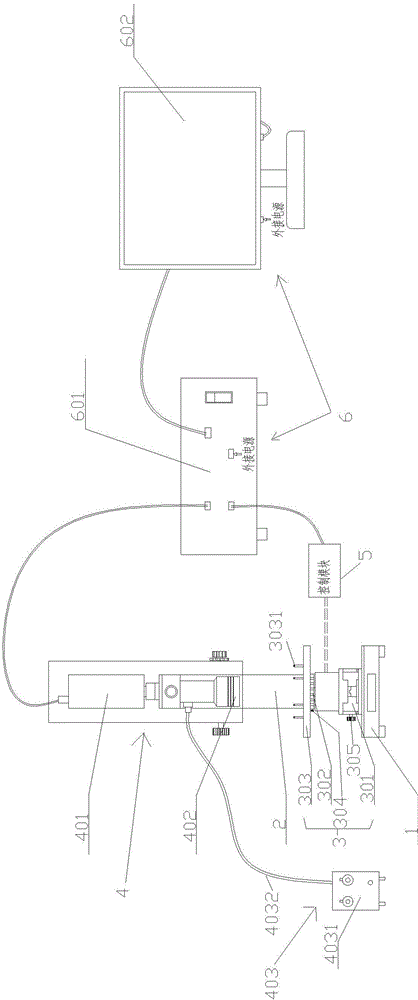

[0026] Such as figure 1 As shown, the wide-view surface defect detection device proposed by the present invention includes a base 1 and a column 2 fixed on the base 1 , and also includes a bearing mechanism 3 , a detection mechanism 4 , a control module 5 and a computer system 6 . The column 2 is provided with a vertical guide rail, and the detection mechanism 4 cooperates with the vertical guide rail on the column to realize the sliding up and down of the detection mechanism.

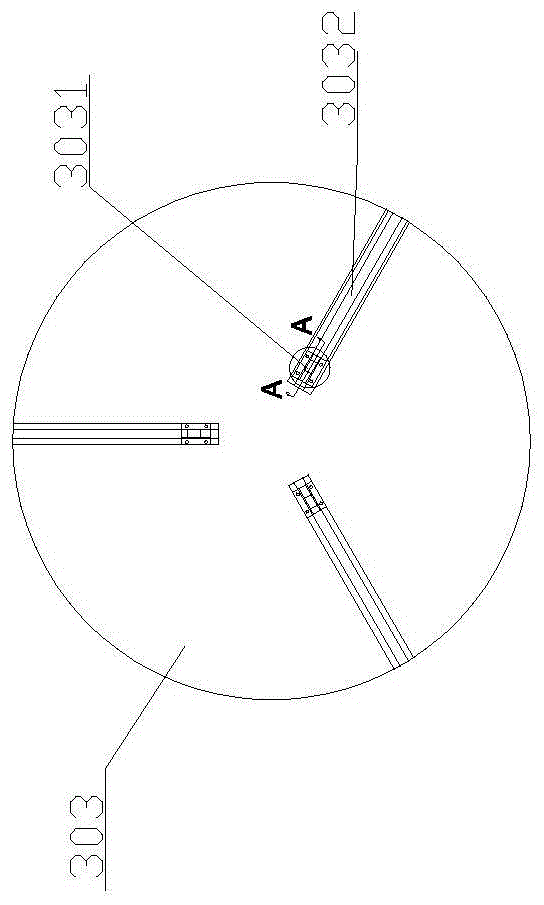

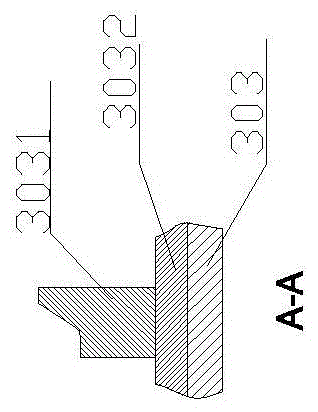

[0027] The carrying mechanism 3 is assembled on the base 1 for carrying and clamping the wafer to be inspected. The carrying mechanism 3 can move along the X axis, and can drive the wafer to rotate horizontally. figure 1 In , the direction perpendicular to the paper is the X-axis direction, which is hereby explained. Column 3 is fixed on one side of base 1 ( figure 1 The middle is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com