Hydraulic loading device with multiple loading force output modes

An output mode, hydraulic loading technology, applied in fluid pressure actuating devices, measuring devices, instruments, etc., can solve problems such as reduction, and achieve the effects of improving test efficiency, reducing test costs, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] This embodiment provides a hydraulic servo cylinder loading device with two functions of dynamic vibration fatigue test and static strength test, which can not only meet the requirements of large load static strength test, but also meet the requirements of high-frequency, high-precision dynamic vibration fatigue test .

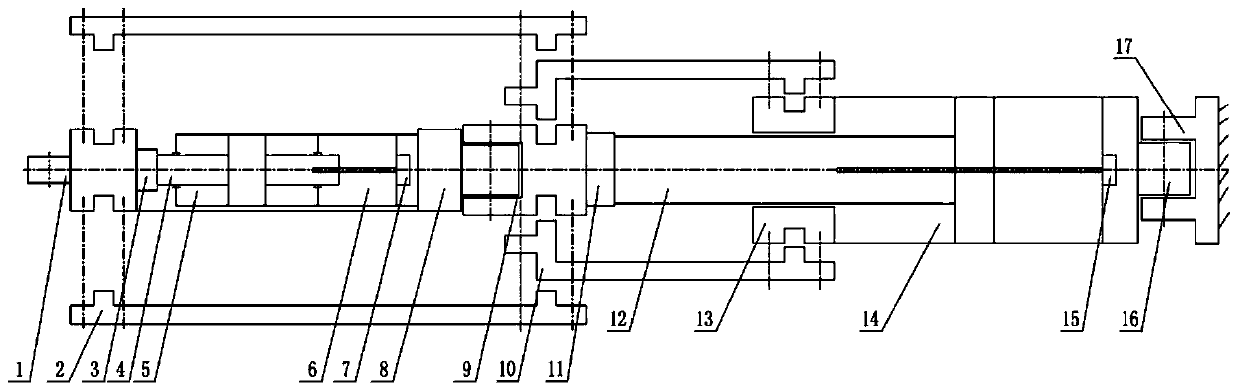

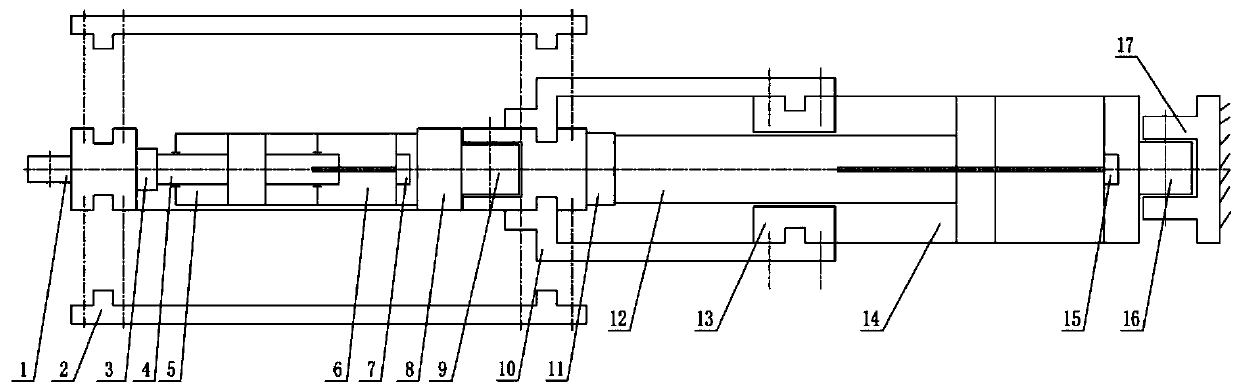

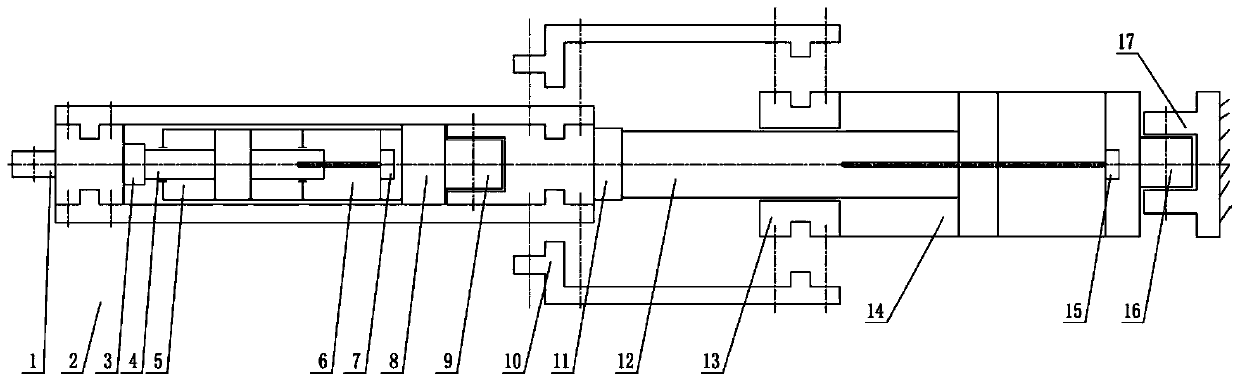

[0022] Such as figure 1 As shown, the hydraulic loading device includes: a dynamic loading assembly and a static loading assembly, wherein the dynamic loading assembly includes; a dynamic loading cylinder composed of a dynamic loading cylinder block 5 and a dynamic loading cylinder piston rod 4, a tension pressure sensor A3, and a dynamic loading cylinder Transition sleeve 6 and dynamic loading cylinder displacement sensor 7; static loading assembly includes static loading cylinder composed of static loading cylinder p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com