Tensile testing machine of steel wire rope

A tensile testing machine and tensile testing technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve grating damage, affect the service life of grating, and cannot detect the elongation of steel wire rope, etc. problem, to avoid easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

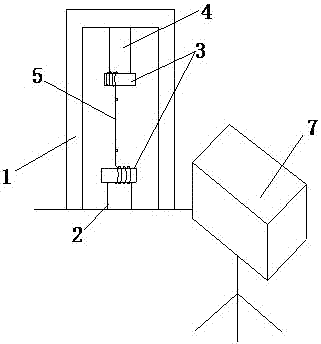

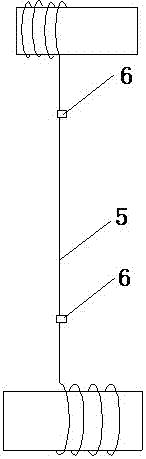

[0012] see figure 1 with figure 2 , the present invention relates to a tensile testing machine for steel wire ropes, the tensile testing machine comprises a tensile machine 1, a base 2 is fixed on the frame of the tensile machine 1, and a lower clamping head is arranged directly above the base 2 3. The top of the upper clamping head 3 is fixed to the frame through the lifting column 4, and the steel wire rope 5 to be tested is placed between the upper and lower clamping heads 3, and the two ends of the steel wire rope 5 are respectively wound and fixed on two clamps. On the holding head 3, the upper holding head 3 controls the lifting column 4 by the air cylinder to pull up the steel wire rope 5 for tensile test. The steel wire rope 5 is respectively pasted with a reflective patch 6 near the holding head 3. The reflective patch 6 Low-energy laser rays can be reflected. The front side of the stretching machine 1 is provided with a laser measuring instrument 7. The laser emitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com