Tram hydraulic brake electronic control device, brake anti-skid control module and brake anti-skid control method

A control method and hydraulic braking technology, applied in the directions of brakes, brake components, control valves and air release valves, etc., can solve the problems of small size of the brake electronic control device, confusing control logic, rubbing wheels, etc. Dynamic and anti-skid adjustment, precise braking and anti-skid adjustment, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

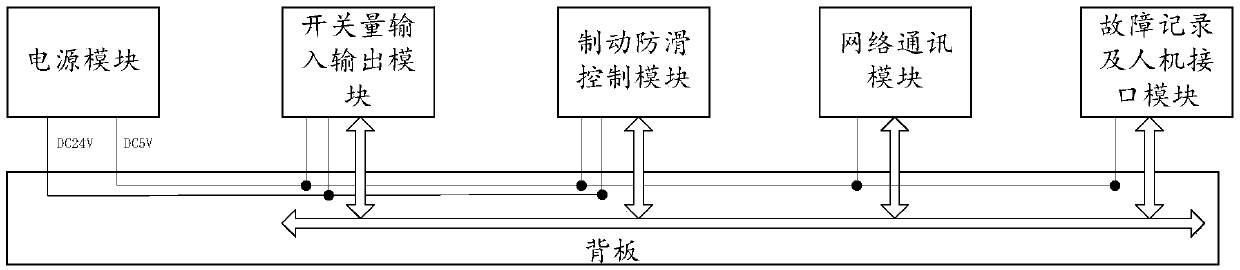

[0041] see figure 1 , The invention discloses an electronic control device for hydraulic braking of a tram. The control device includes a brake anti-skid control module, a switch value input and output module, a fault record and man-machine interface module, a network communication module, a power supply module and a backboard. The power supply module provides electric energy for the above-mentioned other modules, and the above-mentioned other modules communicate through the CAN bus of the backplane to realize braking functions such as safety braking, emergency braking, normal braking and holding braking.

[0042] Compared with the braking system of urban rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com