Irons comprising a heating body in thermal contact with an ironing board

A heating body and ironing board technology, applied in the field of irons, can solve problems such as large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

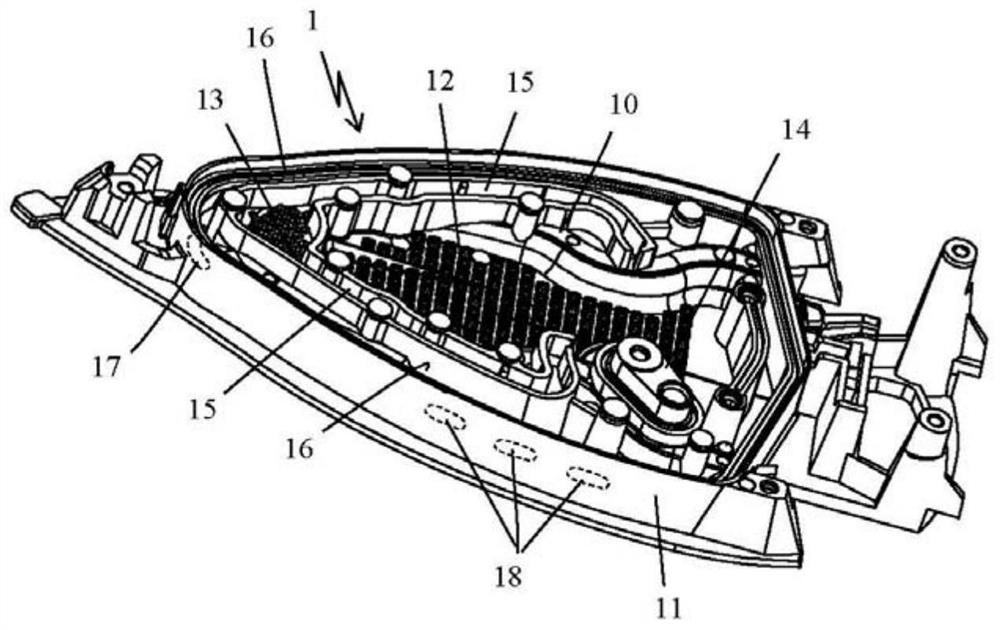

[0039] Only elements necessary for understanding the invention are shown. In order to facilitate the understanding of the drawings, the same reference numerals are used for the same elements in different drawings.

[0040] In this document, the words "horizontal", "vertical", "lower", "upper", "front", "rear" used to describe the iron refer to the iron in use, when the ironing board is placed on a horizontal plane.

[0041] figure 1 Shown is a steam iron comprising a flat ironing board 2 equipped with a steam outlet hole 20, on which a housing 3 of plastic material is placed, which in particular encloses a water container . The housing 3 comprises at its upper end a grip handle 30 and in its rear a base 31 on which the iron can be placed when the ironing phase is not activated.

[0042] refer to Figure 2 to Figure 4 , the ironing plate 2 of the iron has a pointed front end and is thermally and mechanically connected with the heating body 1 integrated in the base of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com