Cylindrical accumulator

A battery, cylindrical technology, applied in the field of alkaline batteries, can solve the problems of large IR voltage drop, high contact resistance, loss and other problems in the melting part, and achieve the effect of excellent current collector structure, high-speed charging and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Some specific examples of the present invention are described below with reference to the drawings.

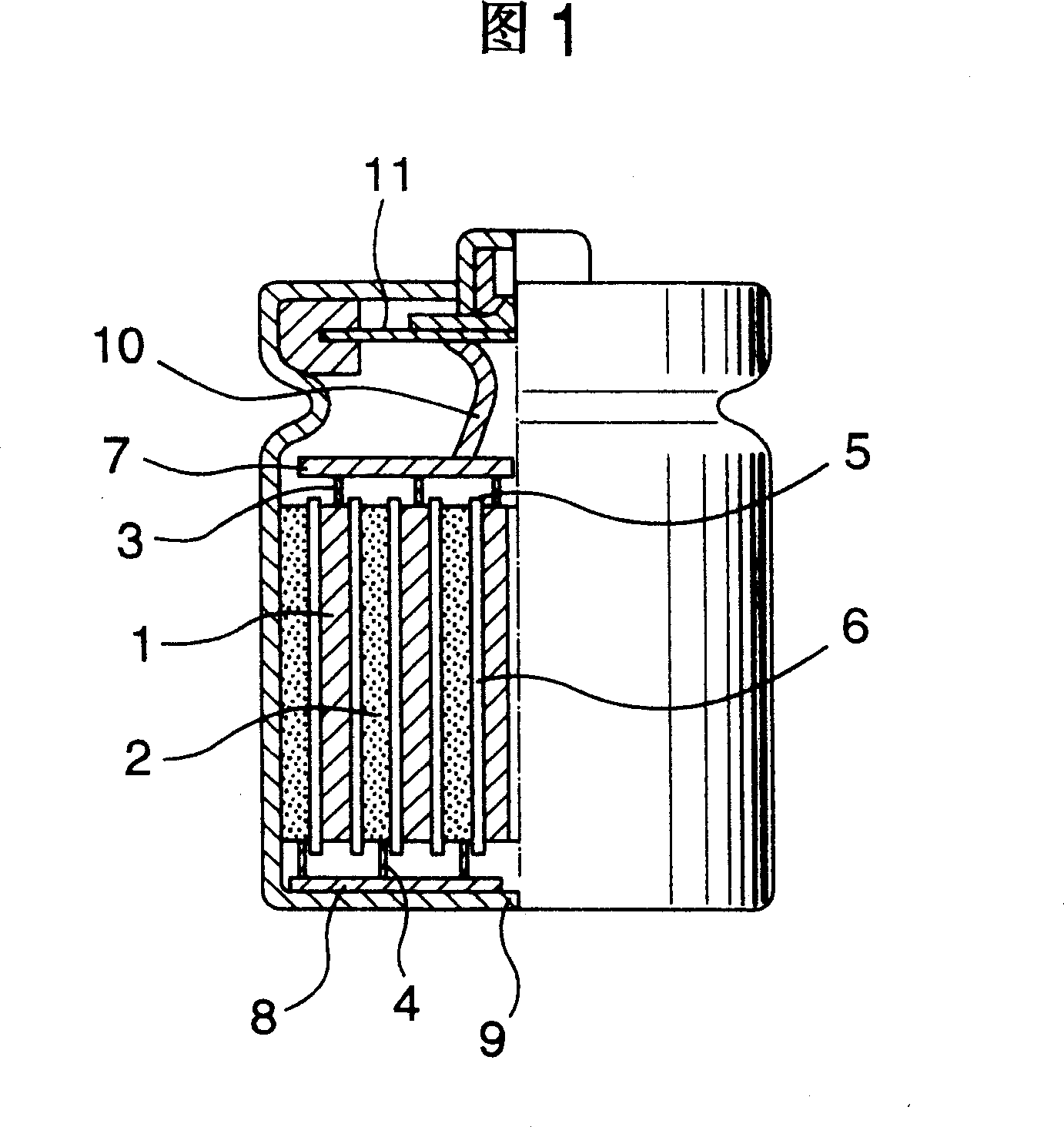

[0030] Fig. 1 is a partial cross-sectional side view of a nickel-cadmium storage battery having a protrusion-free current collecting structure shown in an example of the present invention. Battery A has a diameter of 33mm, a height of 61.5mm, and a rated capacity of 5000 milliampere hours (mAh). The structure of the battery A is detailed as follows.

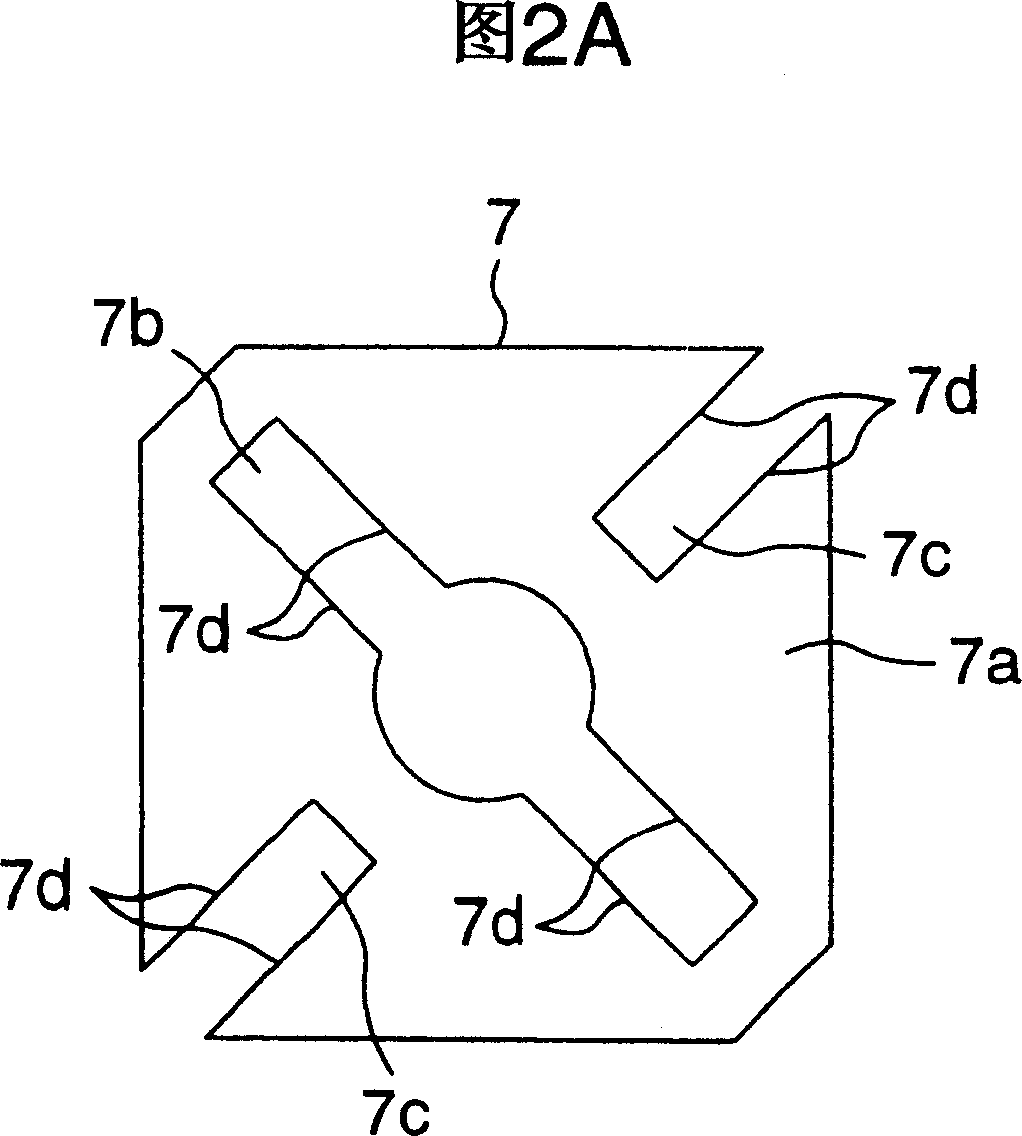

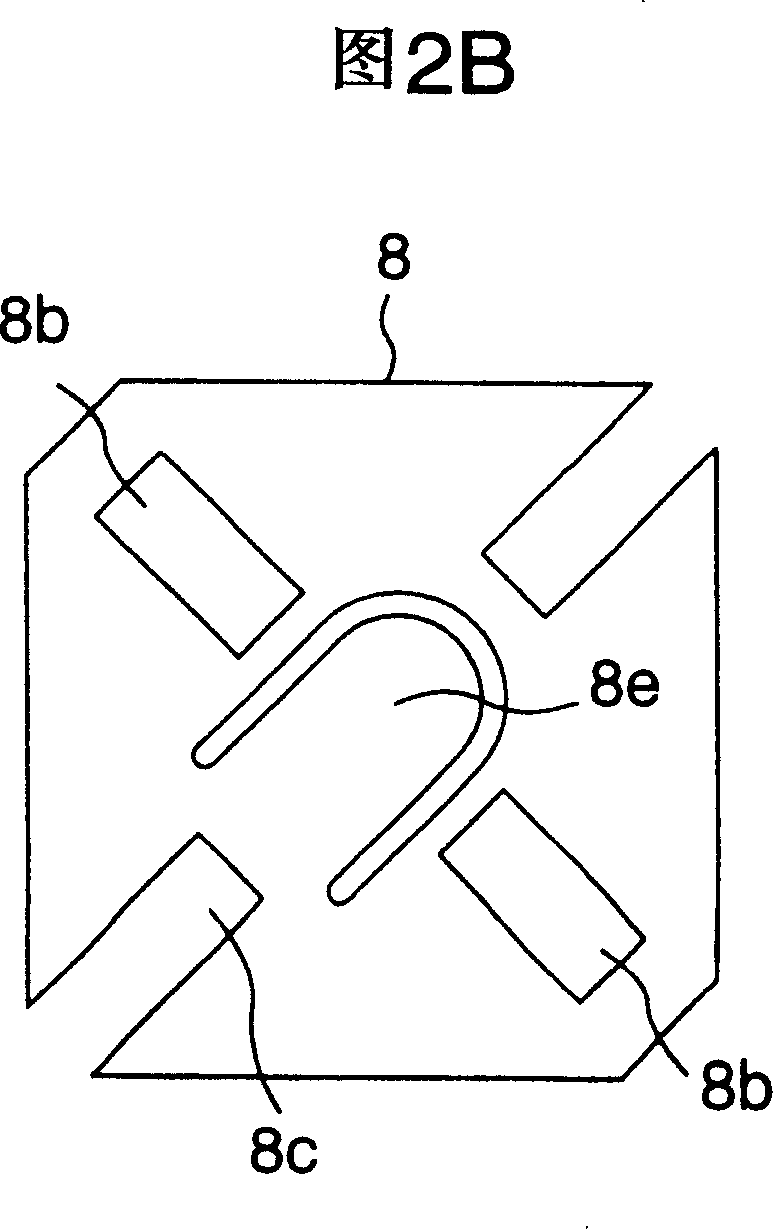

[0031] A sintered nickel positive electrode plate 1 with a thickness of 1.0 mm and a strip-shaped paste cadmium negative electrode plate 2 with a thickness of 0.7 mm are prepared. On the end edges of each electrode plate in the length direction, exposed punching plate parts 3 and 4 are provided with a width of 1.5 mm respectively. Considering the convenience of spirally winding the electrode plate and the firmness of welding, there is a nickel-plated iron plate with a thickness of about 0.08mm for the punching plate 3 of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com