A method for identifying friction-type high-strength bolts falling off in bar connection nodes

A technology for connecting nodes and high-strength bolts, which is used in the field of truss structure health monitoring and safety performance evaluation, and can solve problems such as difficulty in identifying friction-type high-strength bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be described in detail below.

[0045] A method for identifying friction-type high-strength bolts falling off in a rod connecting node according to an embodiment of the present invention includes the following steps:

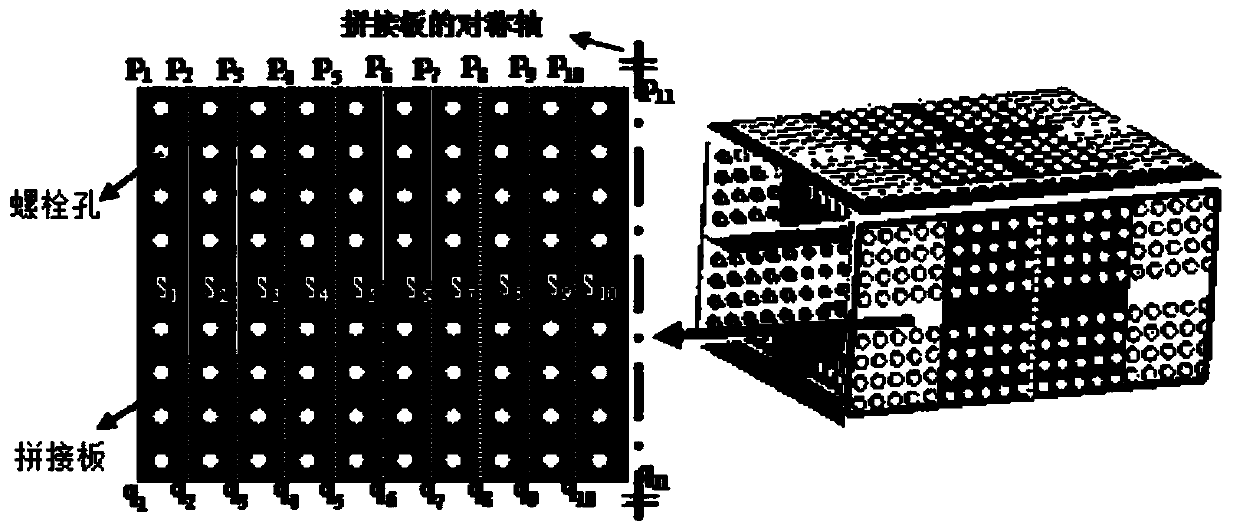

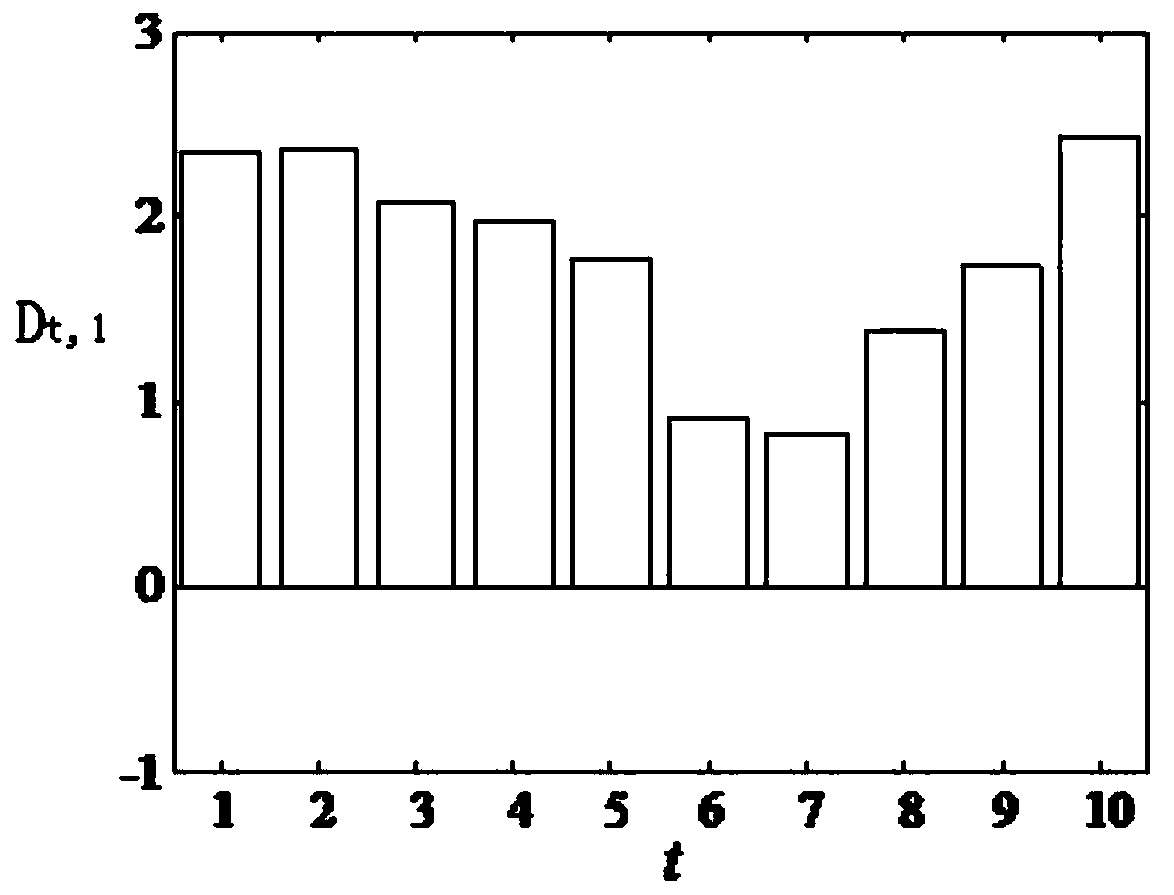

[0046] Step 10) Arrange measuring points on the splicing board of the connecting node of the rod member, set a temperature sensor and a fiber grating strain sensor on each measuring point, use the temperature sensor to monitor and collect the temperature field on the connecting node splicing board, and use the fiber grating strain sensor to monitor and collect the temperature field. Acquire the axial strain on the splice plate of the connecting node.

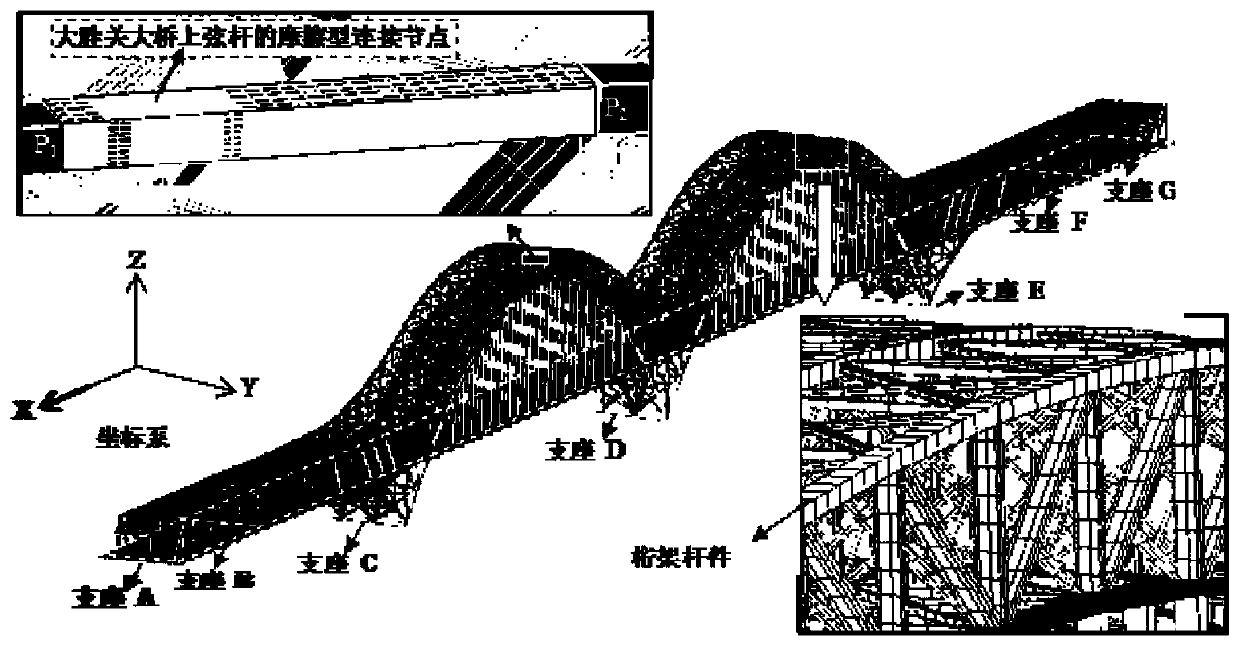

[0047] The step 10) specifically includes: setting the rod connecting nodes to include n rows and m rows of friction bolts, the direction of the rows is the axial direction of the rod, and the direction of the columns is the direction of the cross sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com