Patents

Literature

31results about How to "Increase the frequency of inspections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

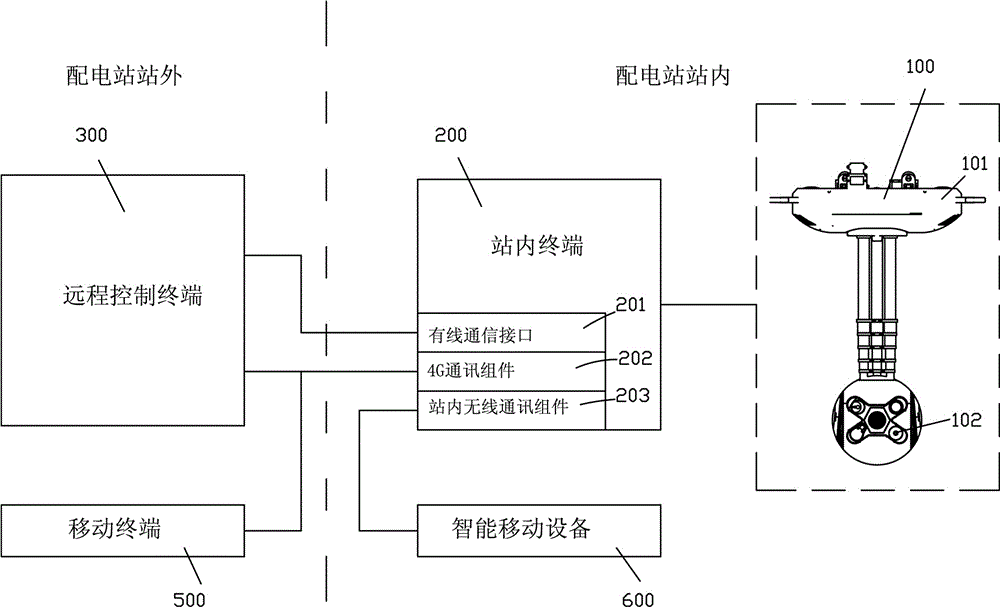

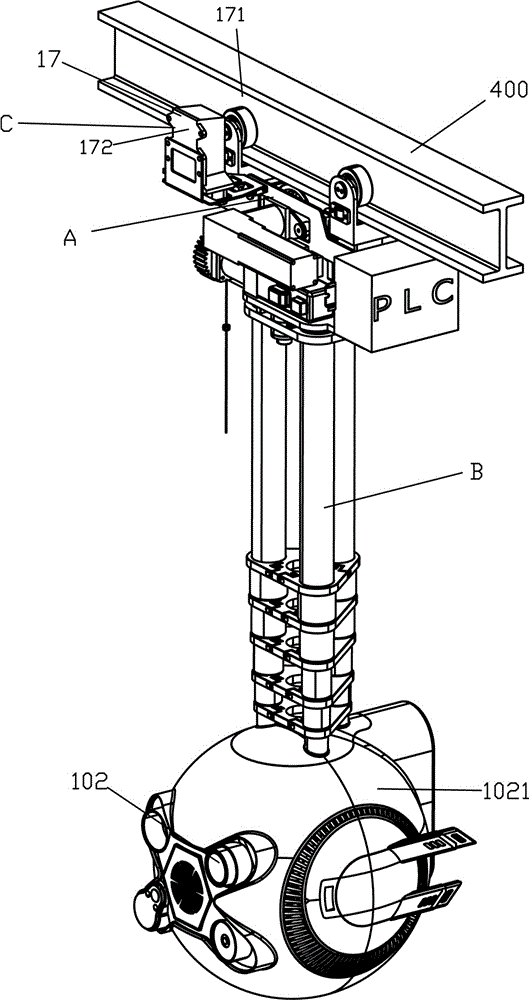

Intelligent inspection robot for power distribution station

InactiveCN106239515AReduce the number of installationsReduce operating costsProgramme-controlled manipulatorDistribution controlSimulation

An intelligent inspection robot for a power distribution station comprises a robot body, an in-station terminal and a remote terminal, wherein the robot body comprises a motion module and a detection module, and the motion module is suspended on a top rail to walk; the top rail is arranged along distribution control points in the power distribution station; the detection module is used for executing inspection, detection, monitoring, fault diagnosis and pre-warning and alarming tasks on the distribution control points; the in-station terminal is used for controlling walking, detection, storage and communication of the robot body; the remote terminal receives a real-time scene image video and detection data transmitted by the in-station terminal for concentrated monitoring. The manual inspection cost can be substantially reduced, and the inspection frequency is improved; the reliability, the authenticity and the accuracy of inspection result data are improved; various monitoring data is collected, and powerful data support is made for analysis and pre-judgement of big data.

Owner:上海永乾机电有限公司

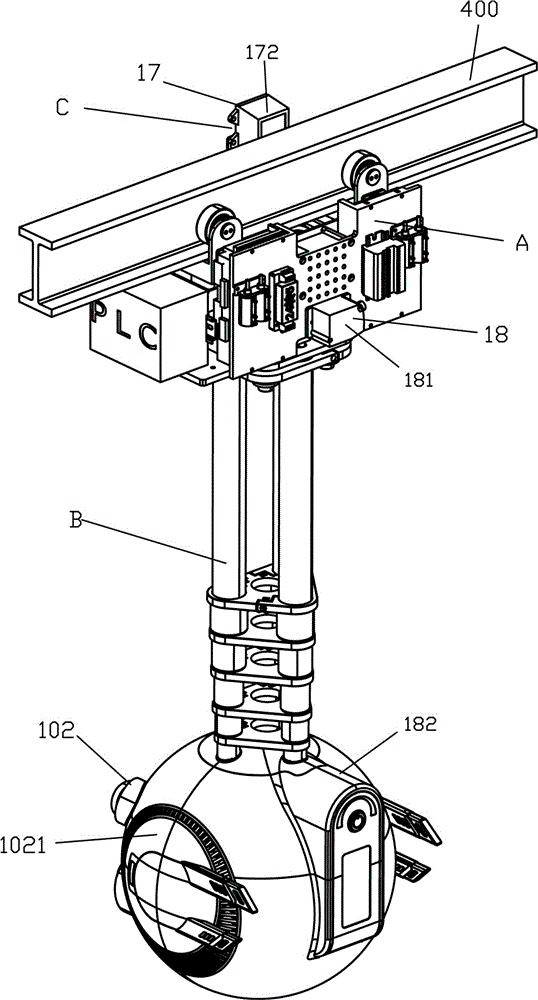

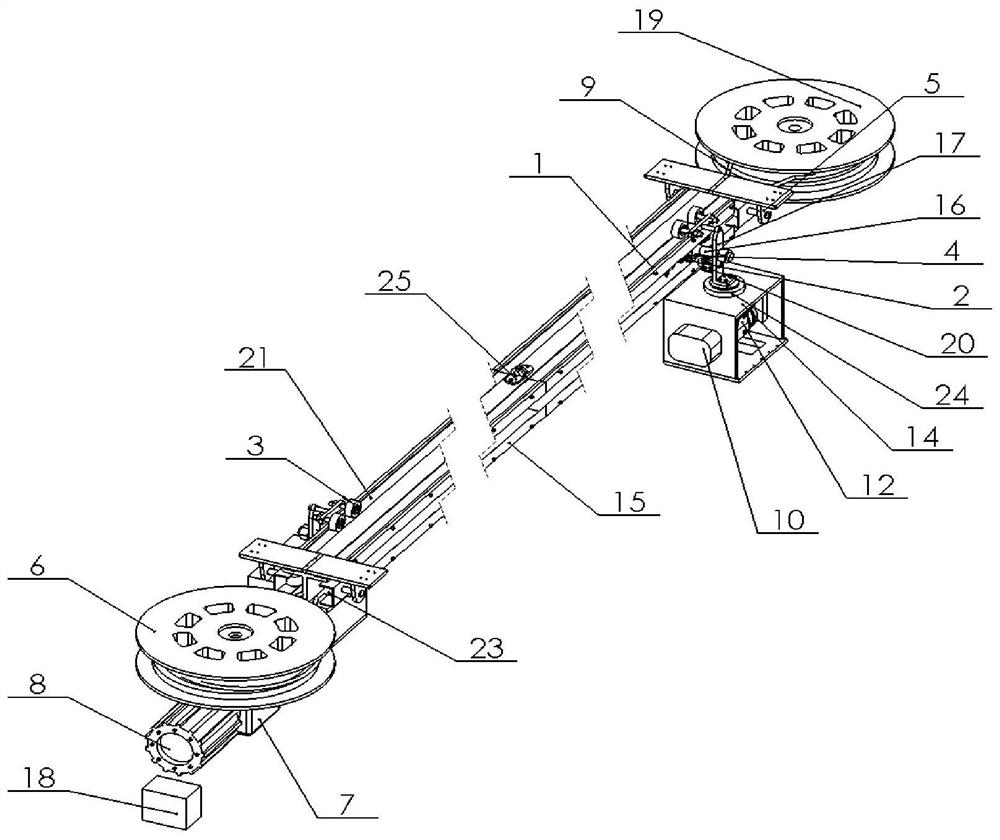

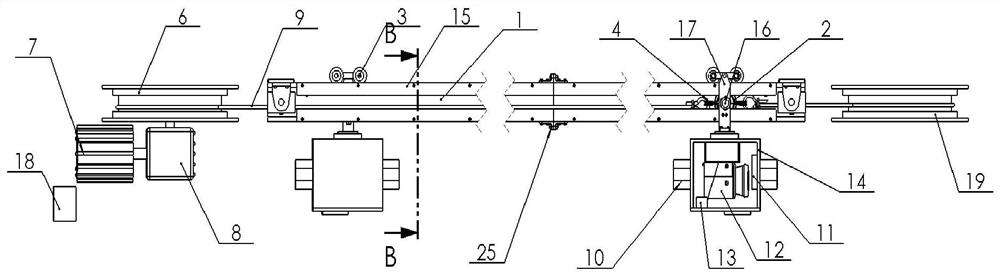

Composite track steel wire rope-driven coal mine patrol robot

PendingCN111706765ASimple organizationAvoid frequent chargingStands/trestlesWinding mechanismsElectrical batteryControl cell

The invention relates to a composite track steel wire rope-driven coal mine patrol robot and the patrol robot is suitable for being used underground coal mines. The composite track steel wire rope-driven coal mine patrol robot comprises a track mechanism, traveling mechanisms, driving modules, inspection modules and a control unit, wherein two traveling mechanisms are provided and respectively arranged on the track mechanism, the driving modules are arranged on the two sides of the track mechanism, and the inspection modules are arranged on the traveling mechanisms; the control unit is arranged at one end of the track mechanism and used for receiving and judging information sent by the inspection module and controlling the start and stop of the whole system; as needed, a battery can be used for power supply, so that work needs can be met; the patrol robot is suitable for being used in the scenes of old mine reconstruction or insufficient underground power supply; and the track mechanism is provided with two single tracks, each traveling mechanism is suspended in each single track, and the two traveling mechanisms move in opposite directions and perform reciprocating inspection, such that the inspection frequency is improved. The composite track steel wire rope-driven coal mine patrol robot is stable in movement, and reciprocating and uninterrupted detection can be realized.

Owner:CHINA UNIV OF MINING & TECH

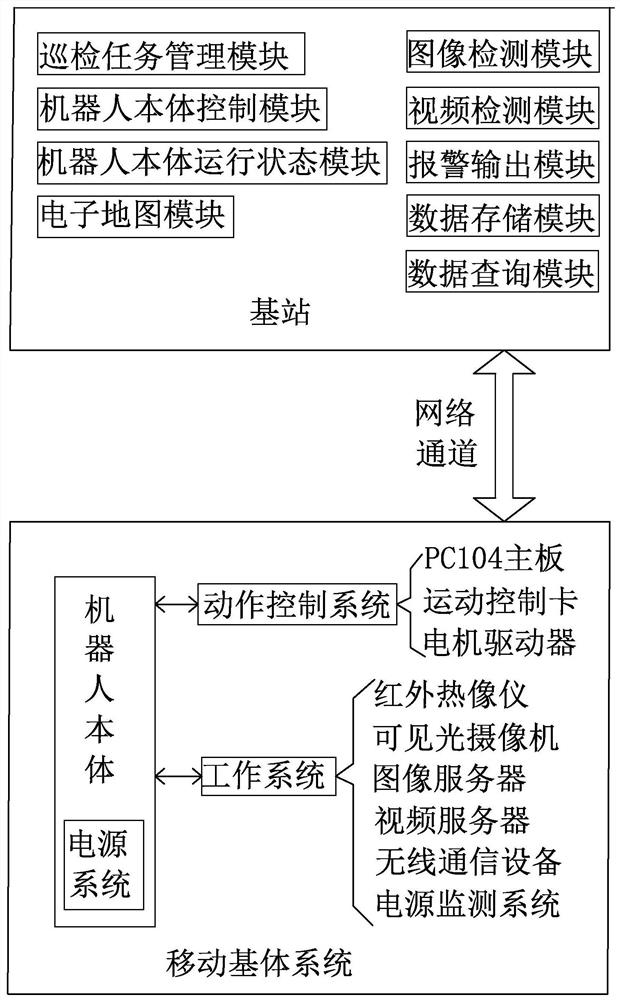

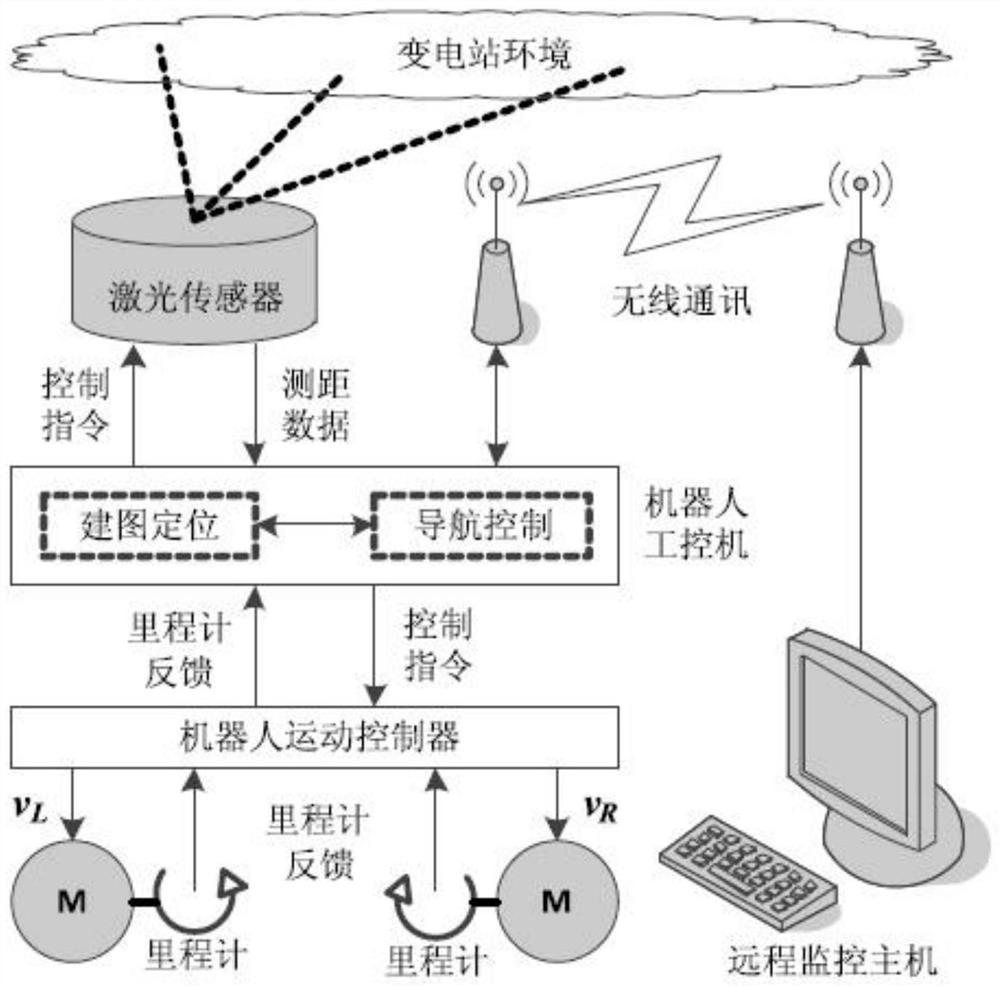

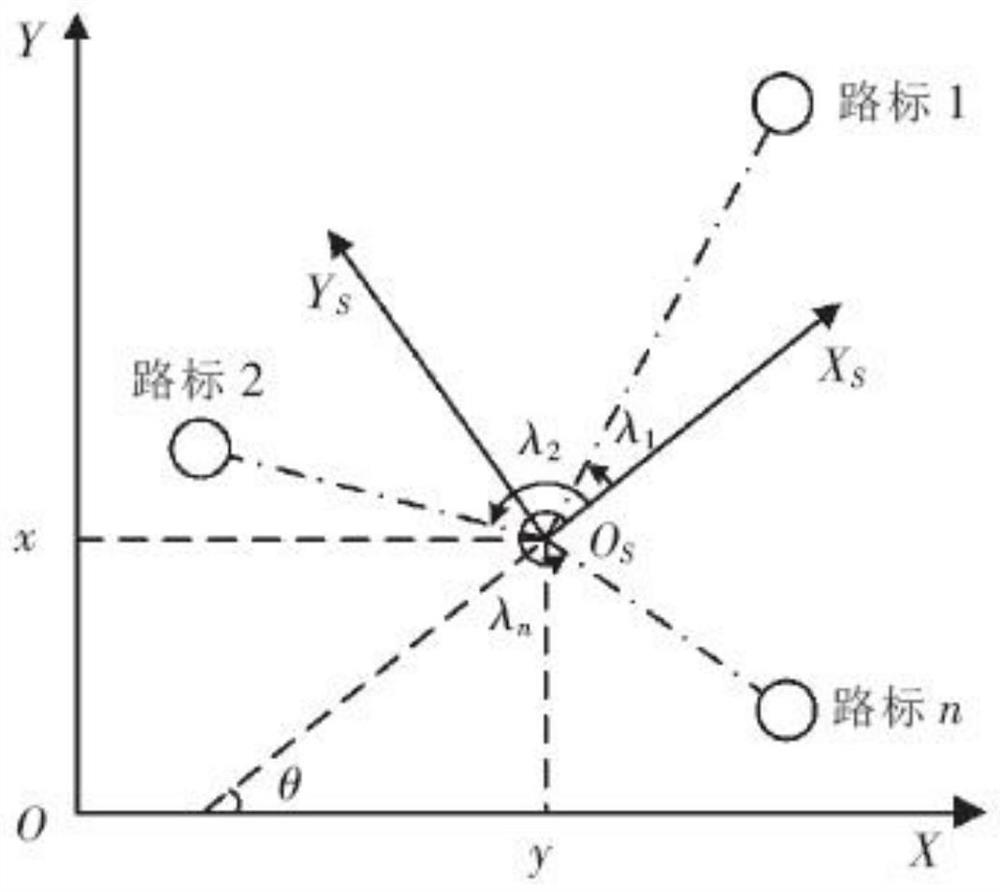

Intelligent substation inspection method based on optimal route planning

ActiveCN112611386AImprove immediacyImprove reliabilityInstruments for road network navigationPath lengthRoute planning

The invention discloses a transformer substation intelligent inspection method based on optimal route planning. The method comprises steps that an inspection task management module transmits an action instruction to a robot body to generate an inspection task; according to the routing inspection method, a calculation mode of a preferred path is adopted, and the path lengths, the detection time and the fault probabilities of different routing inspection areas are comprehensively considered by adopting the weight coefficient aij so that the cost paid for detecting each path can be comprehensively given. The method is advantaged in that the paths in the directed graph are screened according to the methods from the first step to the sixth step on the basis of the weight coefficient, the optimal path with the minimum detection cost can be obtained by traversing various paths in the algorithm, and the action instruction is correspondingly generated according to the sequence of the routing inspection areas through which the optimal path passes, so routing inspection efficiency is improved; and the robot body is controlled to move from one inspection area to the next inspection area.

Owner:HANGZHOU SHENHAO TECH

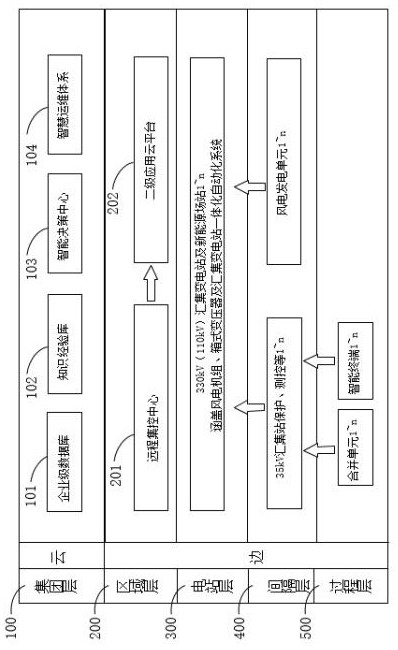

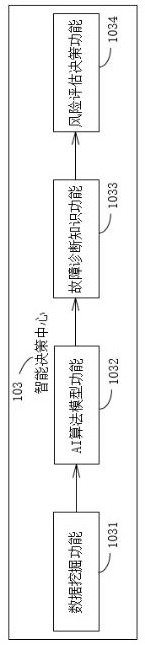

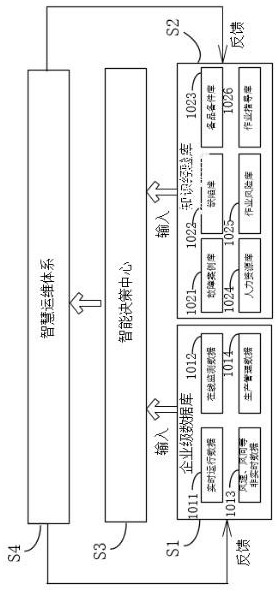

Production operation management system and method for wind power plant

PendingCN113450065AReduce operating costsImprove risk management and control capabilitiesDigital data information retrievalCircuit arrangementsDistributed structureBusiness process

The invention discloses a production operation management system and method for a wind power plant, the production operation management system for the wind power plant comprises a five-layer four-network distributed structure, and the five-layer four-network distributed structure comprises a group layer, a region layer, a power station layer, a spacing layer and a process layer which are connected by adopting a cross-domain cooperation and cloud side sharing architecture mode; the group layer comprises an enterprise-level database, a knowledge experience library, an intelligent decision-making center and an intelligent operation and maintenance system; the regional layer comprises a remote centralized control center and a secondary application cloud platform; through an intelligent decision-making center which takes wind power intelligent early warning, fault diagnosis and intelligent operation and maintenance which are uniformly deployed in a group layer as a core and a hierarchical application mode of a region layer, health assessment is carried out on the operation state of field equipment, so that service processes such as maintenance, overhaul, spare parts, personnel arrangement and misoperation-preventive locking are effectively triggered, and intelligent linkage and quick-response intelligent operation and maintenance between related equipment of each power station on site and between the equipment and operation and maintenance personnel are realized.

Owner:POWERCHINA XIBEI ENG

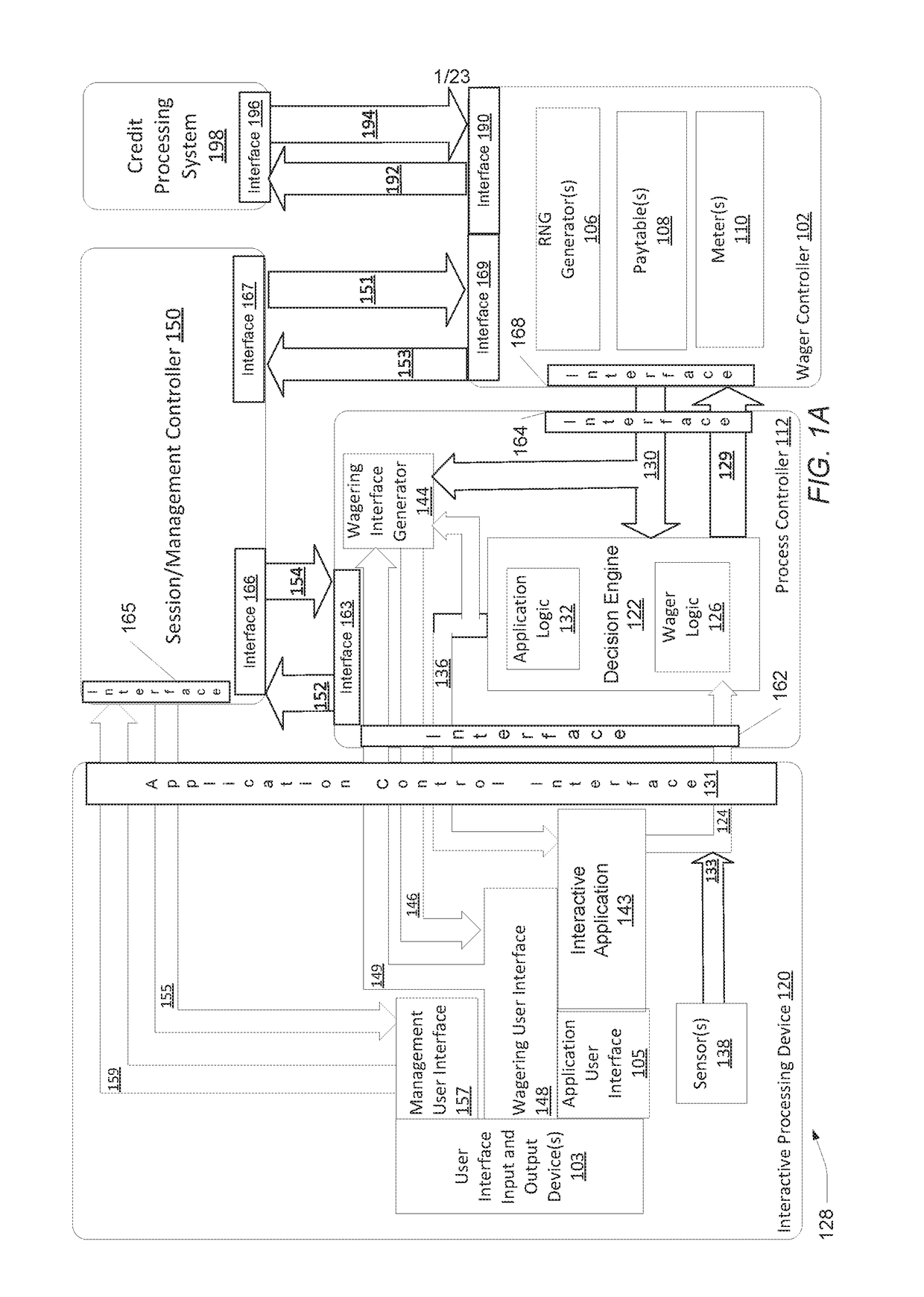

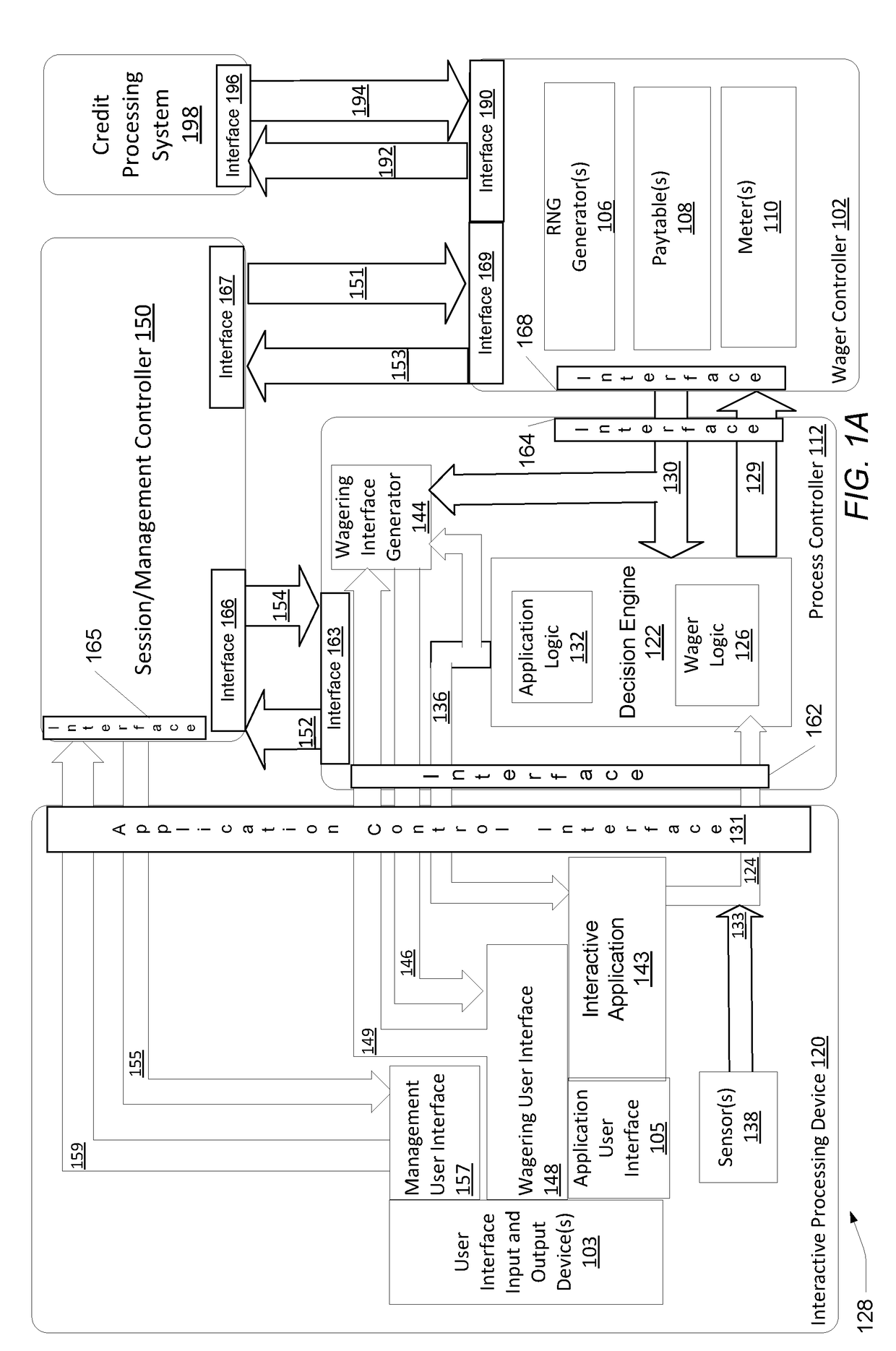

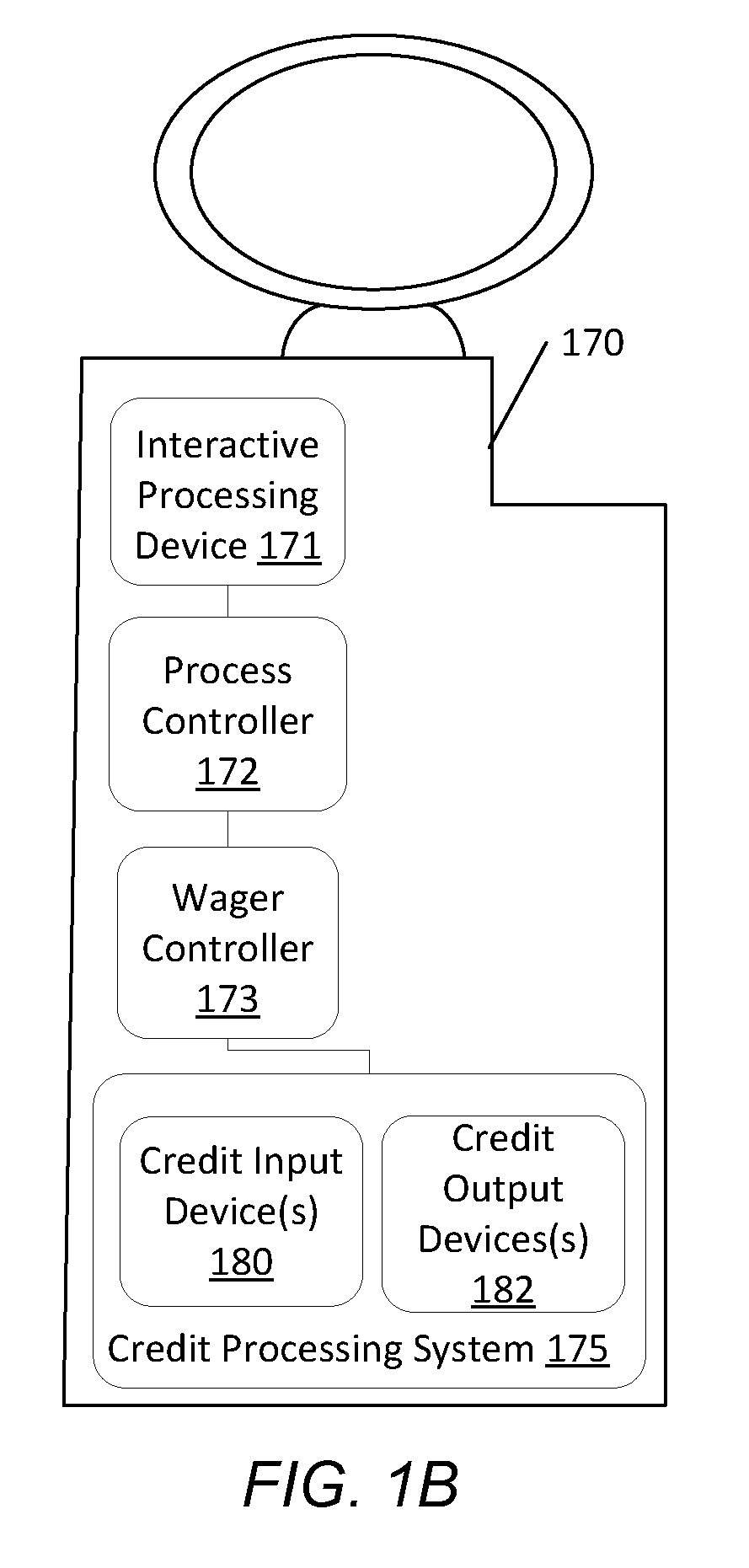

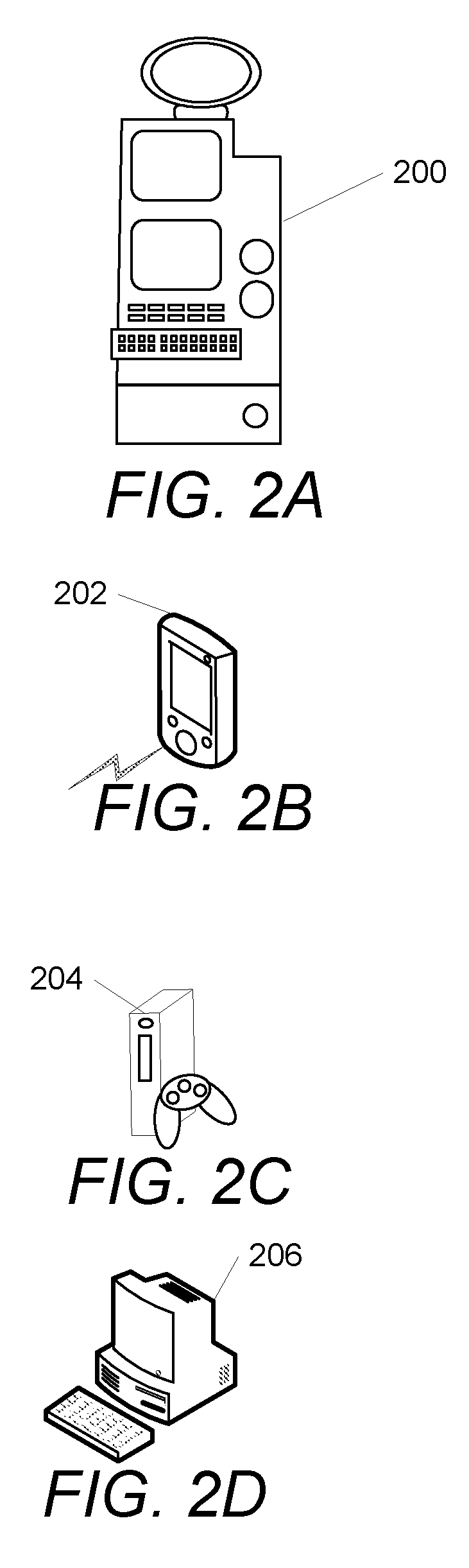

Gwc production monitoring interleaved wagering system

InactiveUS20170256138A1Convenient operation and managementIncrease the frequency of inspectionsApparatus for meter-controlled dispensingHuman–computer interactionProcess control

An electronic gaming machine using a game world credit monitoring module, an interactive controller, a process controller, and a wager controller to provide an interactive application that triggers wagers on the wager controller based on user interactions within the interactive application and allows the electronic gaming machine to make adjustments to the interactive application difficulty level to achieve a desired RTP based on game world credit generation within the interactive application.

Owner:GAMBLIT GAMING

An airport navigation display terminal automatic inspection system

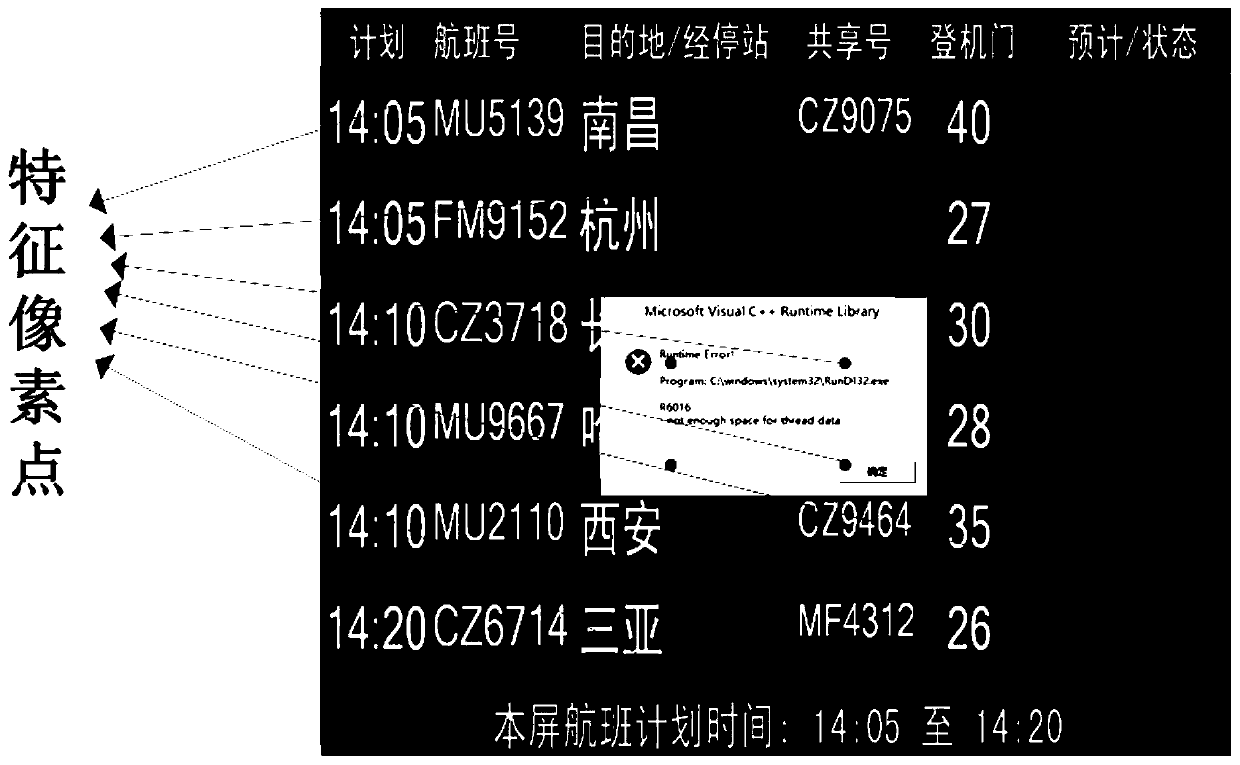

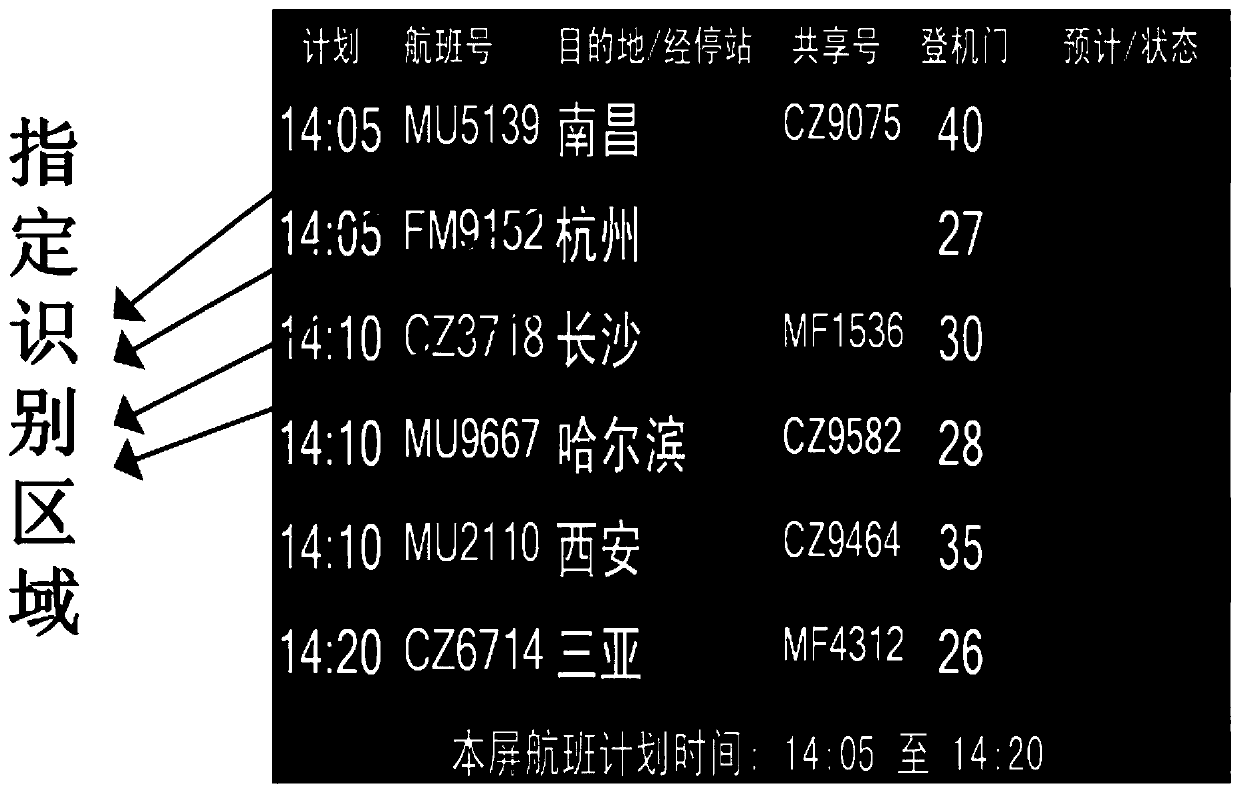

ActiveCN109886431AFind faults in timeRealize automatic inspectionRegistering/indicating working of vehiclesCharacter and pattern recognitionComputer graphics (images)Computer terminal

The invention discloses an automatic inspection system for an airport navigation display terminal. The system comprises an information acquisition module used for carrying out screen capture on a screen of each aerial display terminal and generating a screen capture picture; a state analysis module used for extracting picture information of a screenshot picture of each navigation display terminal,comparing and analyzing the picture information with standard information pre-stored in a database and corresponding to each navigation display terminal, and judging whether the display state of eachnavigation display terminal is normal or not and whether the display information is accurate or not; and a monitoring module used for monitoring a comparative analysis result of the state analysis module. According to the invention, the screenshot of the aerial display terminal is regularly and automatically collected; the information in the screenshot is intelligently extracted and compared withthe standard information, whether the display state of the navigation display terminal is normally displayed or not and whether the flight information is accurately displayed or not are automaticallyjudged, the automation, intelligentization and real-time performance of the routing inspection are achieved, and the integrity and the accuracy of the information displayed by the navigation displaysystem terminal are improved.

Owner:BEIJING CAPITAL INT AIRPORT CO LTD

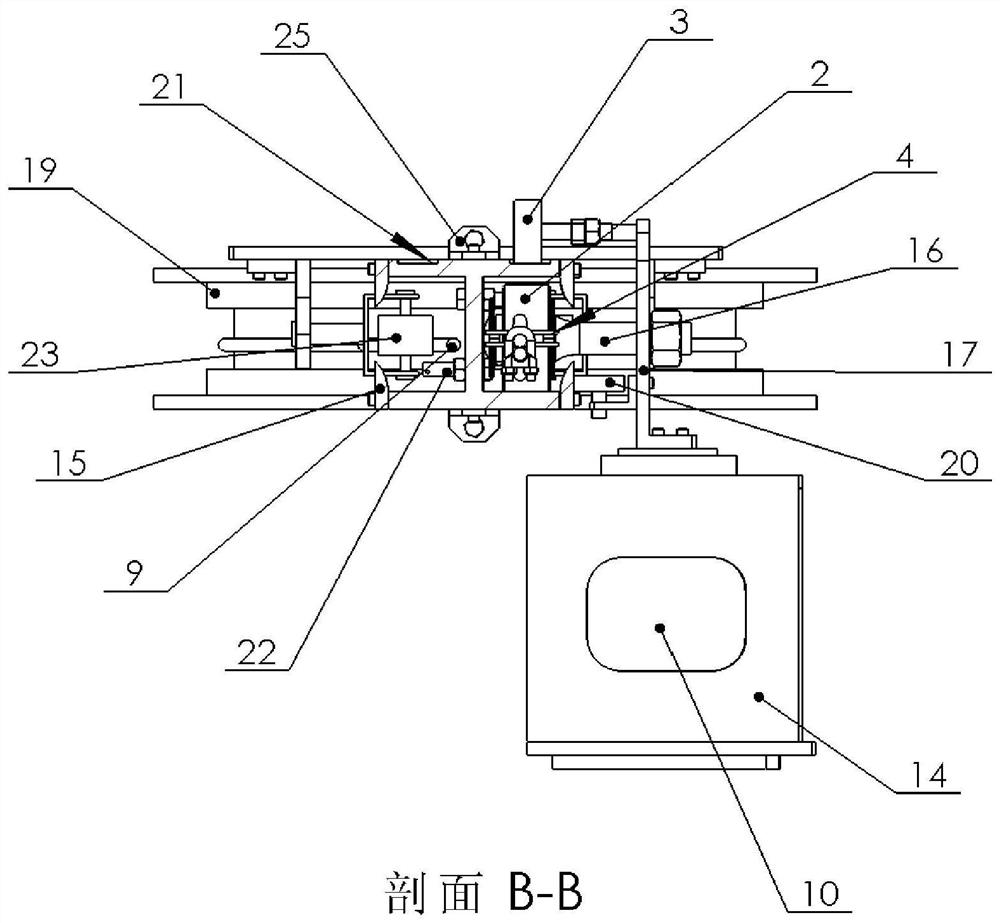

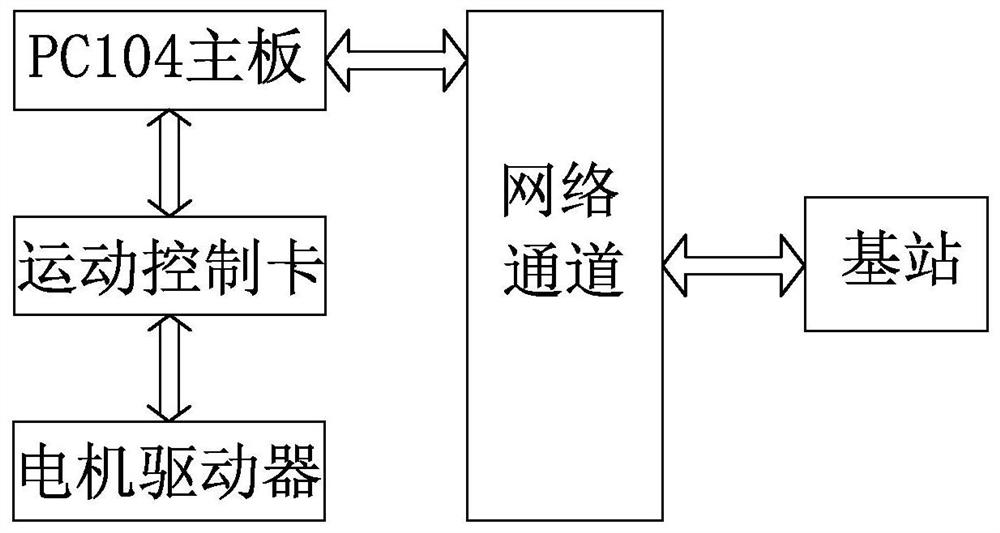

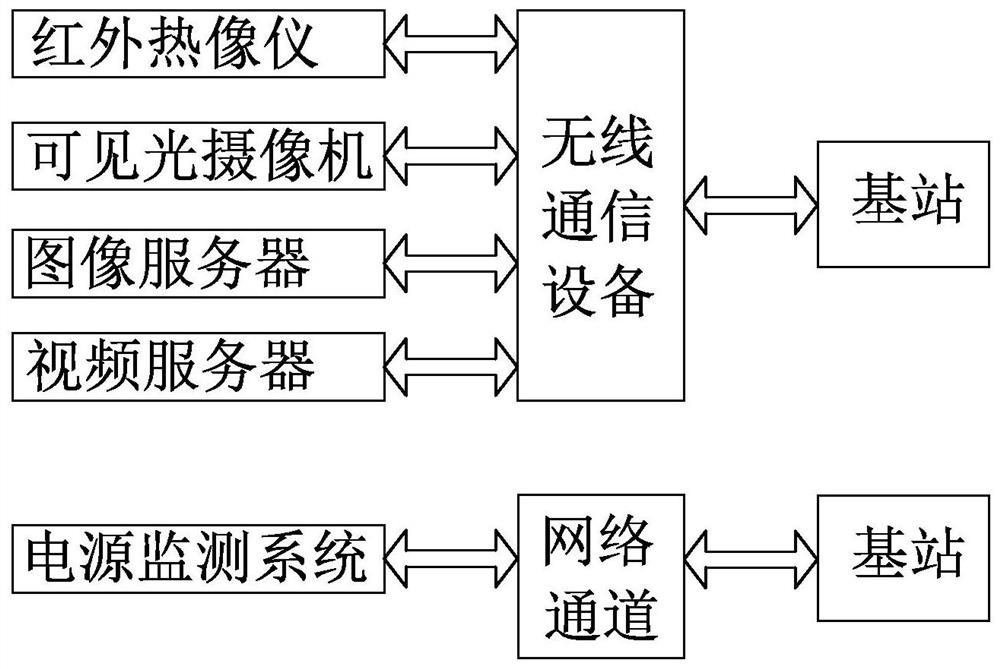

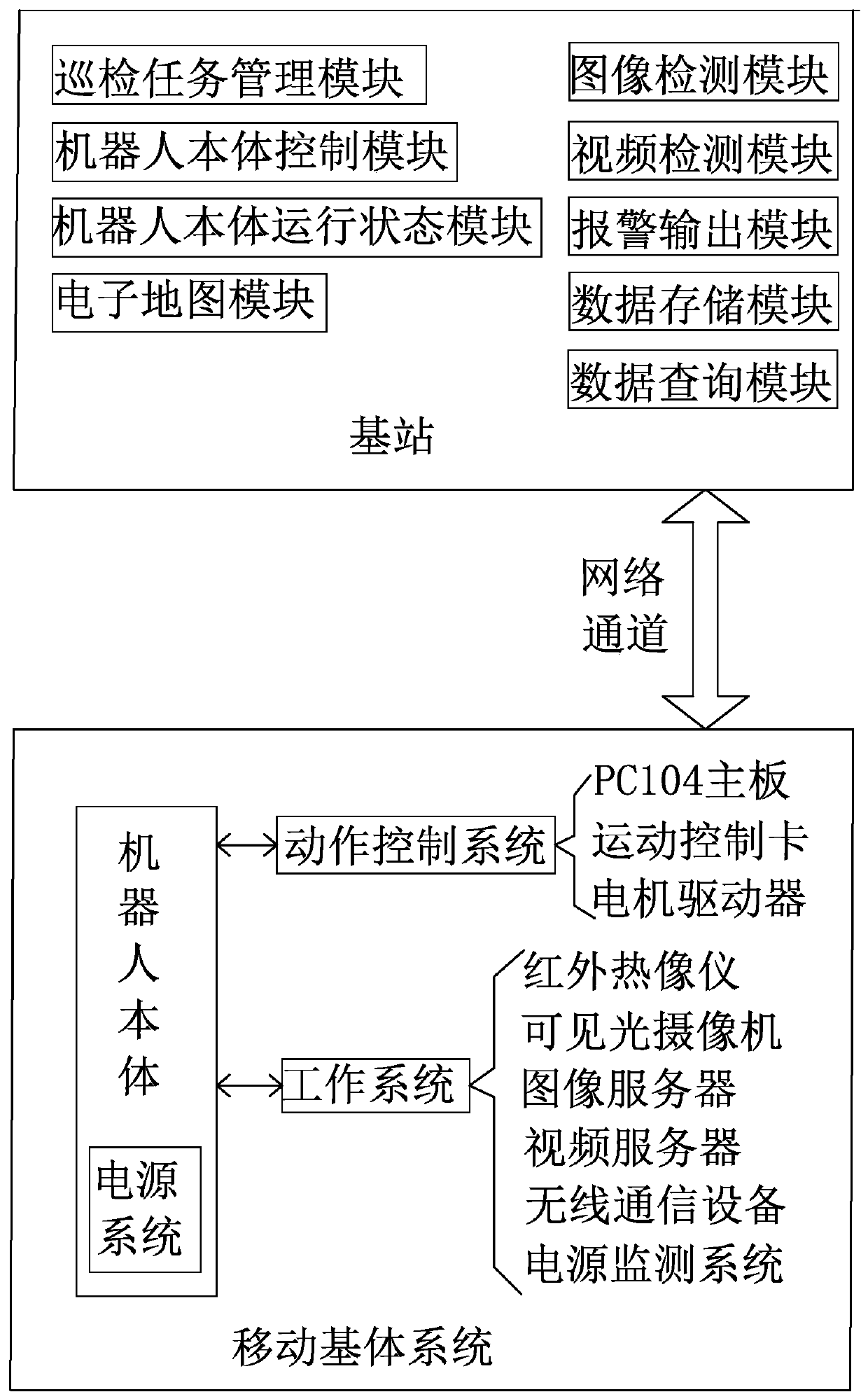

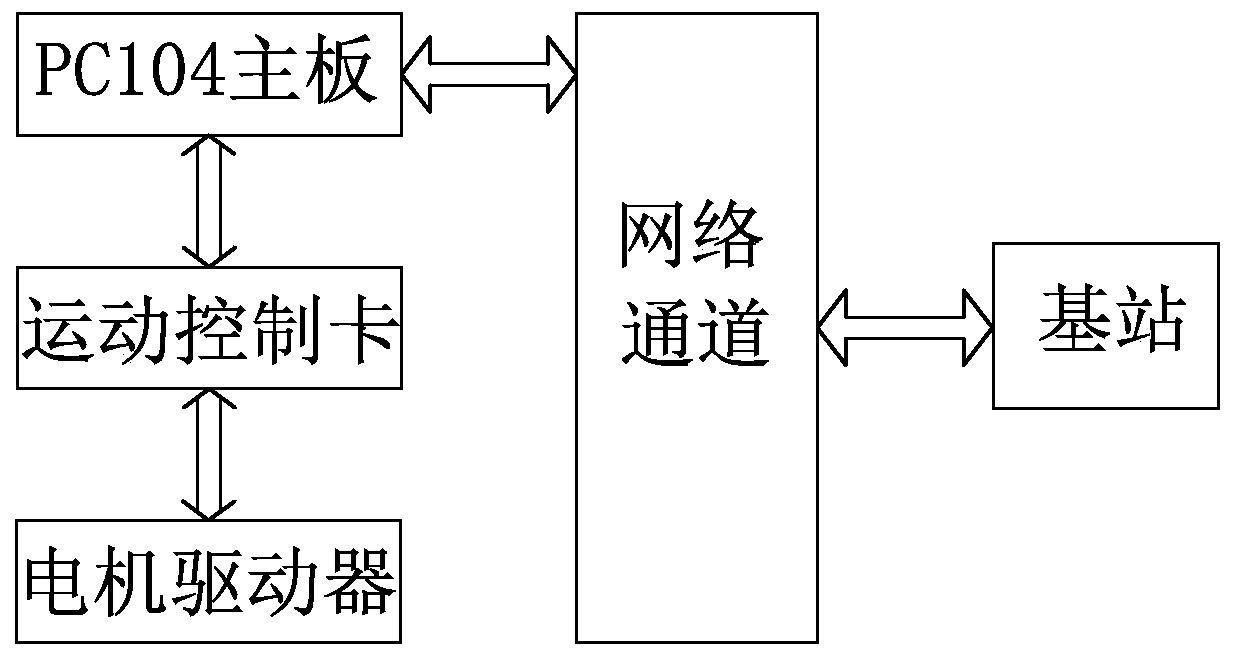

Transformer substation intelligent inspection system

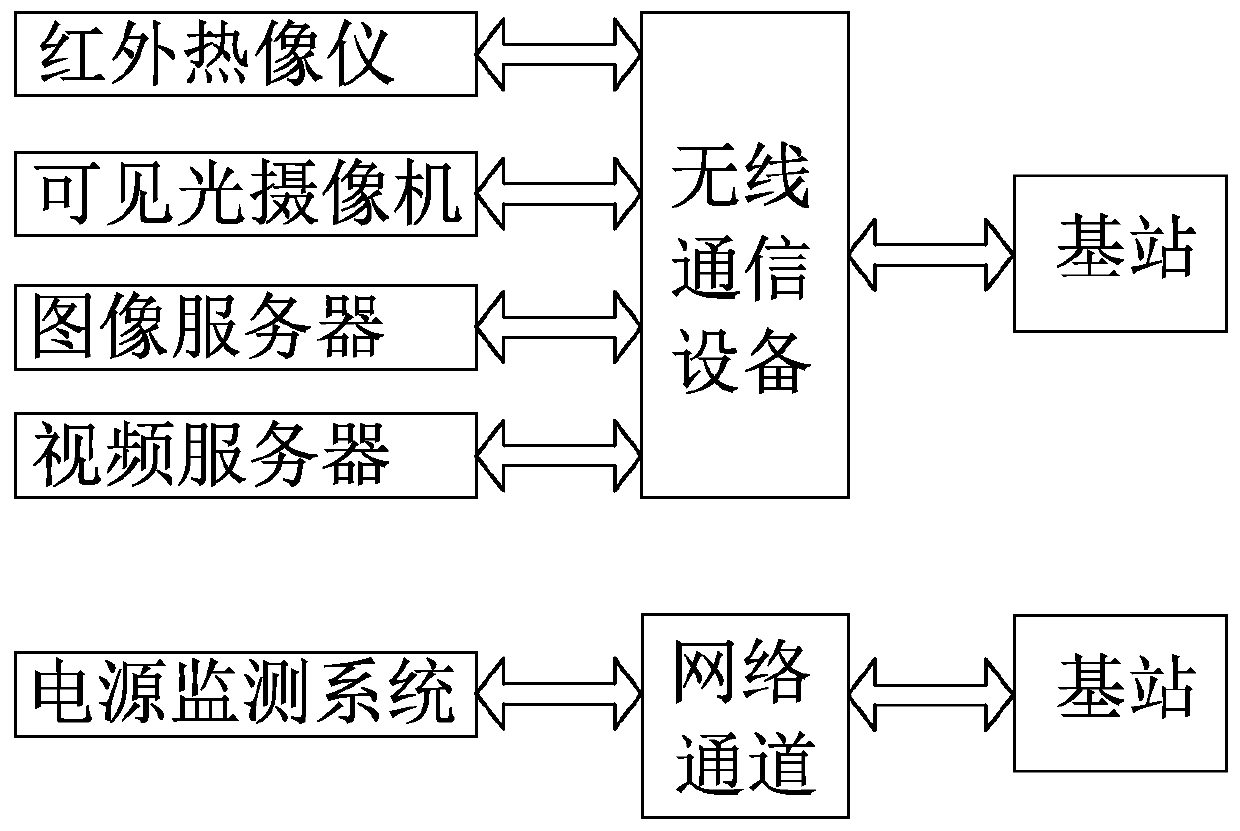

ActiveCN109861387AImprove timelinessReduce inspection labor costsCircuit arrangementsNavigation instrumentsTransformerControl system

The invention discloses a transformer substation intelligent inspection system. The transformer substation intelligent inspection system comprises a mobile substrate system, a network channel and a base station. The mobile substrate system is connected with the base station through the network channel; the mobile substrate system comprises a robot body and a motion control system and a work systemwhich are arranged on the robot body; the motion control system receives a motion command issued by the base station and performs motion control for the robot body; and the work system receives a work command issued by the base station and drives the robot body to detect a transformer substation, and the work system can transmit detection information to the base station through the network channel. The transformer substation intelligent inspection system can greatly reduce the manual cost of the inspection, can improve the inspection efficiency and can improve the instantaneity, reliability,authenticity and accuracy of the inspection result data.

Owner:HANGZHOU SHENHAO TECH

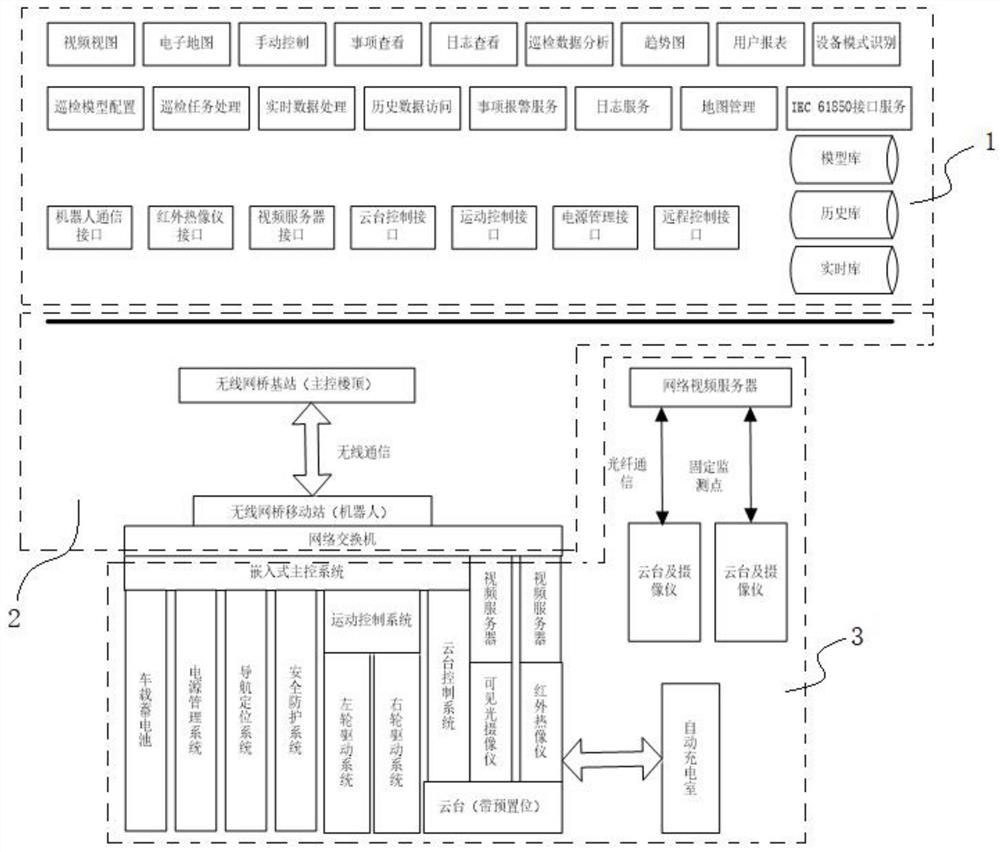

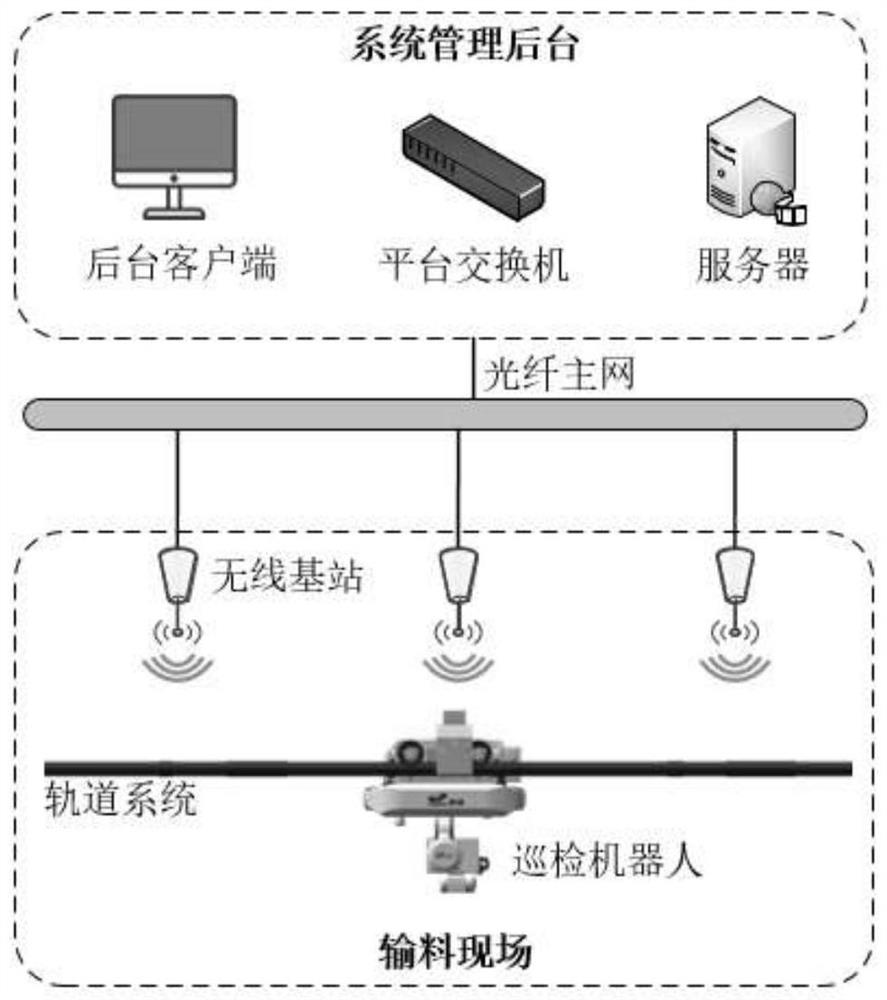

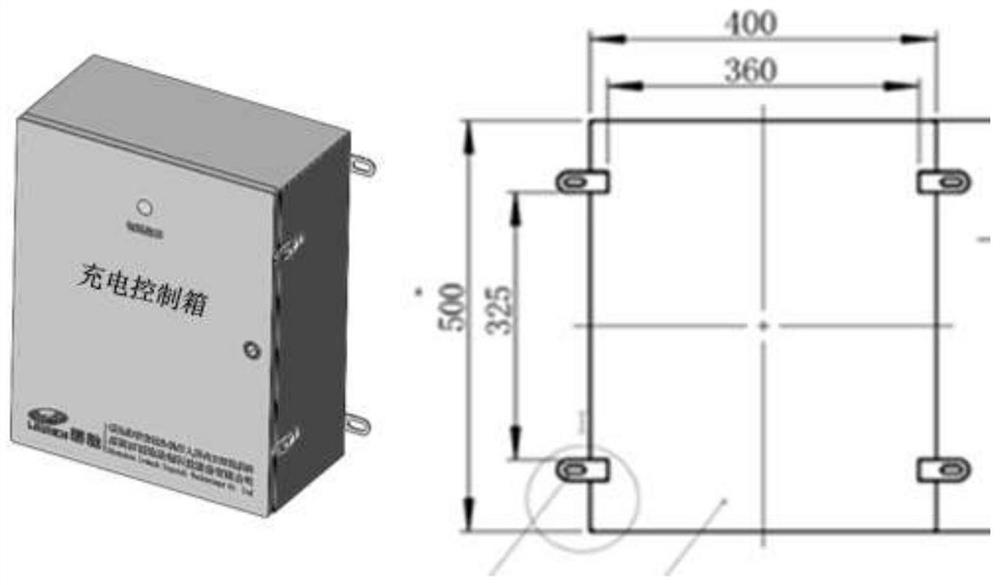

Intelligent inspection system for traction substation

PendingCN113708491AAutomatic chargingIncrease the frequency of inspectionsTelevision system detailsChecking time patrolsVideo monitoringEmbedded system

The invention provides an intelligent inspection system for a traction substation. The system comprises a base station layer, a communication layer and a terminal layer, and the base station layer communicates with the terminal layer through the communication layer; the base station layer is used for receiving, processing and displaying data, and is also used for realizing automatic identification and alarm of equipment defects through image processing and mode identification; the terminal layer comprises an inspection robot, a charging chamber and a fixed video monitoring module, the inspection robot is connected with the monitoring background through wireless communication, and the fixed video monitoring module is connected with the monitoring background through optical fiber communication; a charging mechanism is arranged in the charging chamber and is used for charging the inspection robot; and the fixed video monitoring module comprises a camera and a network video server, the camera is arranged on a tripod head, the camera is used for shooting a fixed monitoring point, the camera is connected with the network video server through optical fiber communication, and the network video server communicates with the base station layer through the communication layer. The system can replace operation and maintenance personnel to carry out daily inspection work.

Owner:中国铁路北京局集团有限公司天津供电段

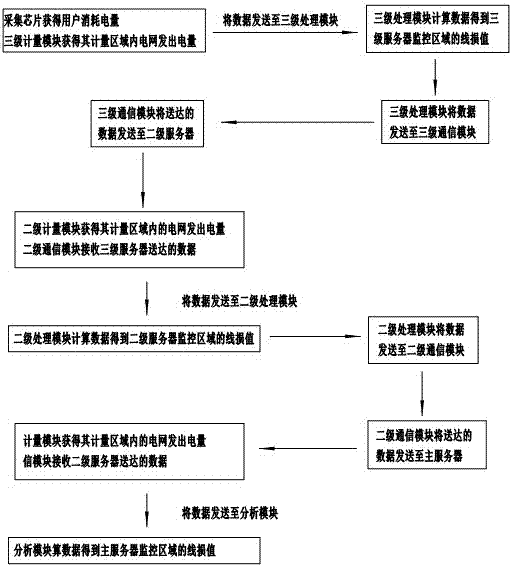

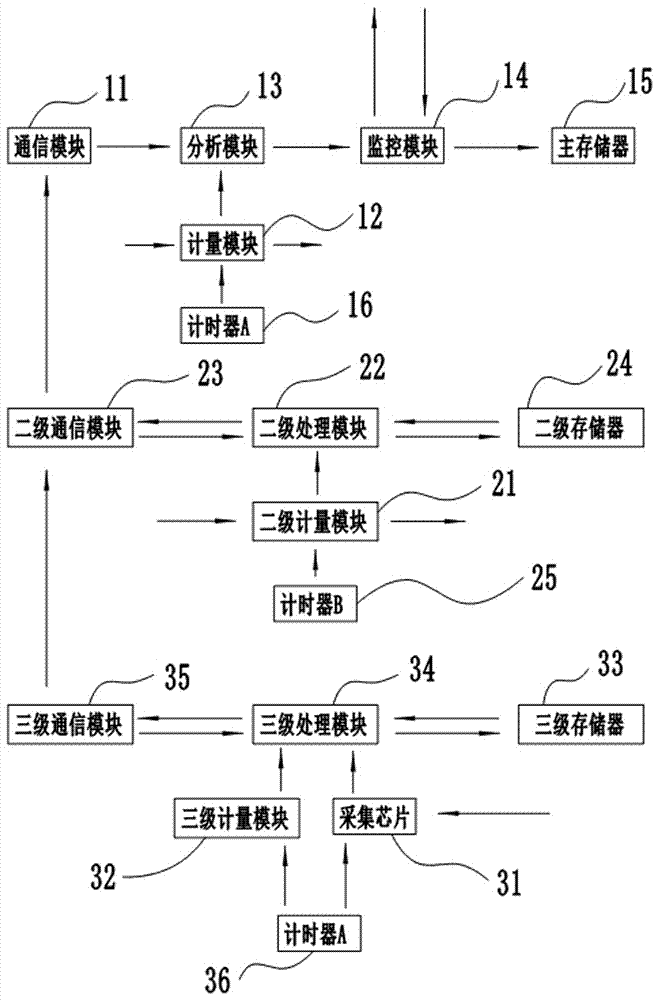

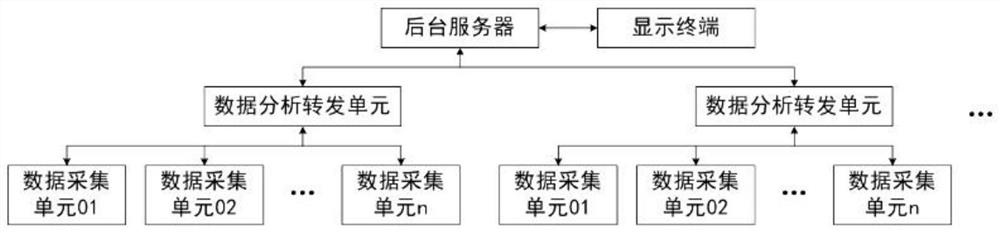

Distributed line loss determination and power grid monitoring equipment and method

InactiveCN107482767AClear hierarchy of monitoringImprove work efficiencyCircuit arrangementsThree levelComputer module

The invention discloses a distributed line loss determination and power grid monitoring equipment and method. The equipment comprises a main server, at least one second-level server connected with the main server and at least one third-level server connected with the second-level server, wherein the third-level server is at least connected with an external user terminal, the third-level server comprises an acquisition chip, a third-level metering module, a third-level memory, a third-level processing module and a third-level communication module, the second-level server comprises a second-level metering module, a second-level processing module, a second-level communication module and a second-level memory, and the main server comprises a communication module, a metering module, an analysis module, a monitoring module and a main memory. Data of the power grid can be conveniently acquired through three-level design, a line loss value can be acquired through calculation on the basis of the acquired data, the data is accurate, calculation is rapid, an abnormal data area can be found out through comparing an actual line loss value and a theoretical line loss value, an overhaul and maintenance instruction can be timely emitted, and power grid operation stability is improved.

Owner:STATE GRID CORP OF CHINA +2

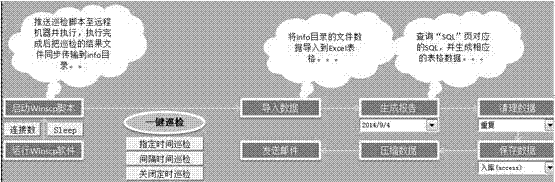

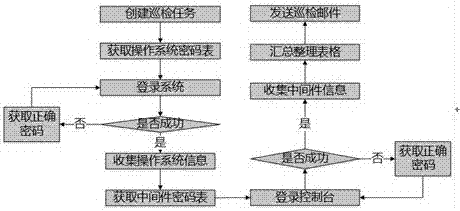

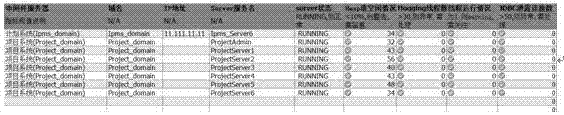

Automated inspection method of middleware

InactiveCN107391374AReduce operation and maintenance workloadImprove operation and maintenance work efficiencySoftware testing/debuggingRemote computerComputer science

The invention discloses an automated inspection method of middleware. The method includes the following steps that Winscp software is run and a Winscp script is started, and a tour-inspection script is pushed to a remote computer and executed; a tour-inspection process is run, a tour-inspection result is obtained, and a tour-inspection result file is synchronized to an info catalogue; the file data of the info catalogue is imported to an Excel table; the corresponding sql is queried, and the corresponding table data is generated; the duplicated data in the table is cleared; the data is saved in an access database; the data is compressed and emailed to a reserved email box of an operator.

Owner:GUANGDONG POWER GRID CO LTD INFORMATION CENT

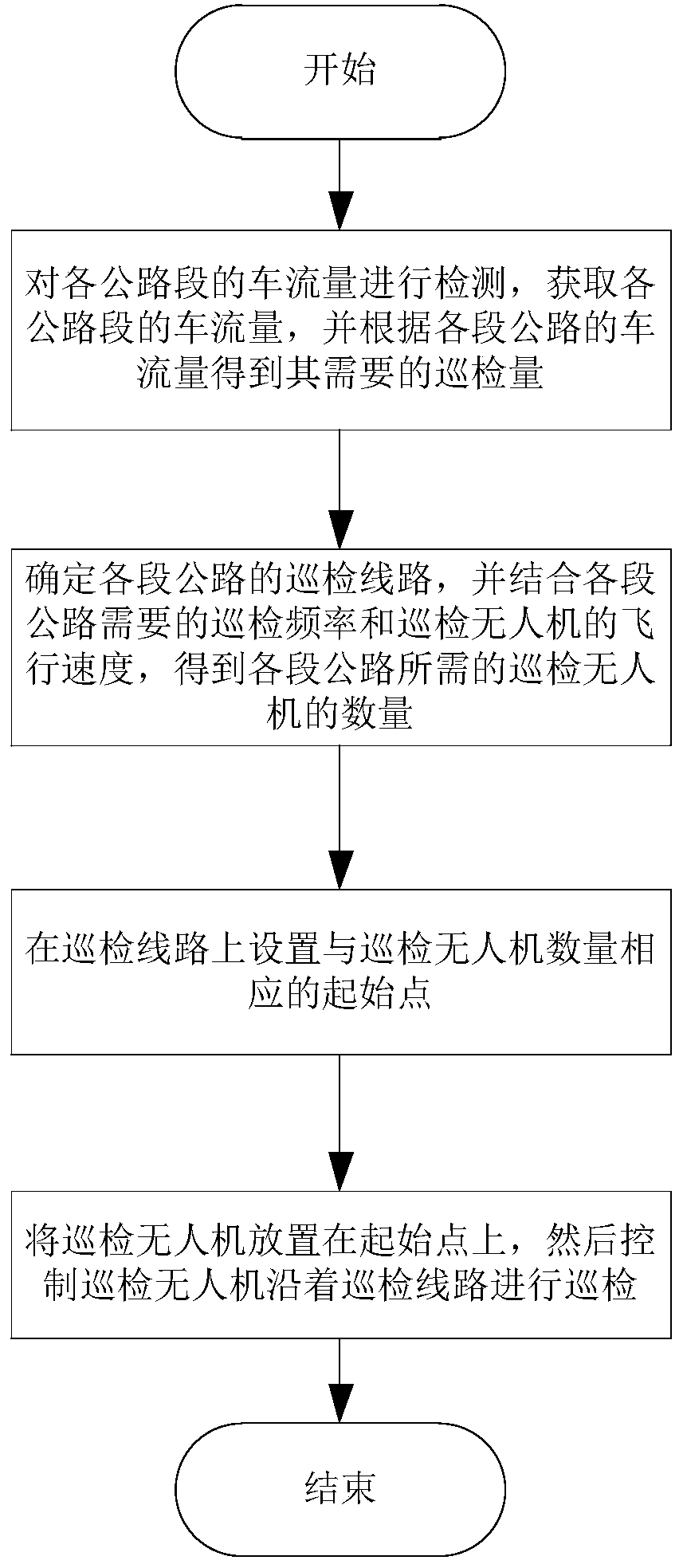

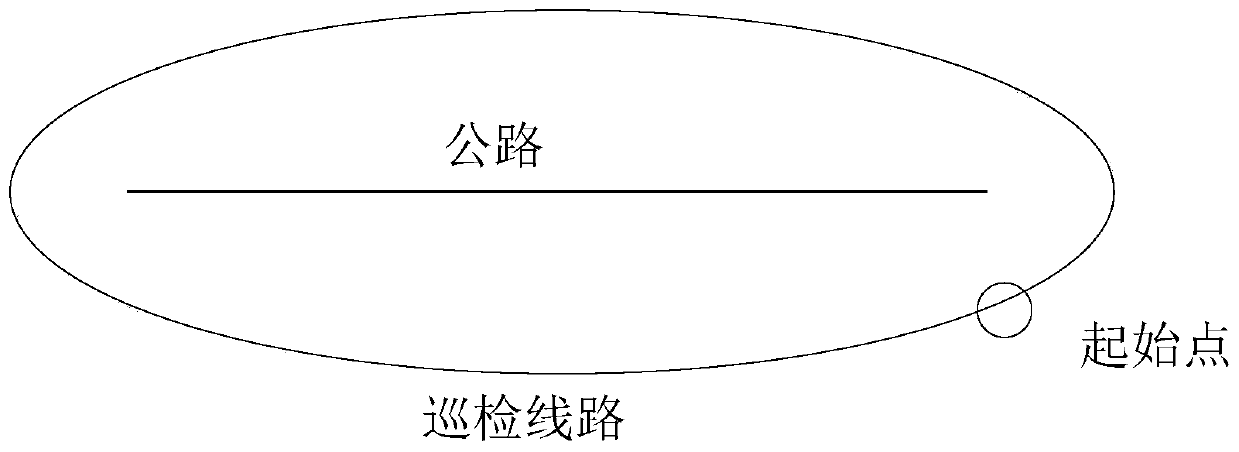

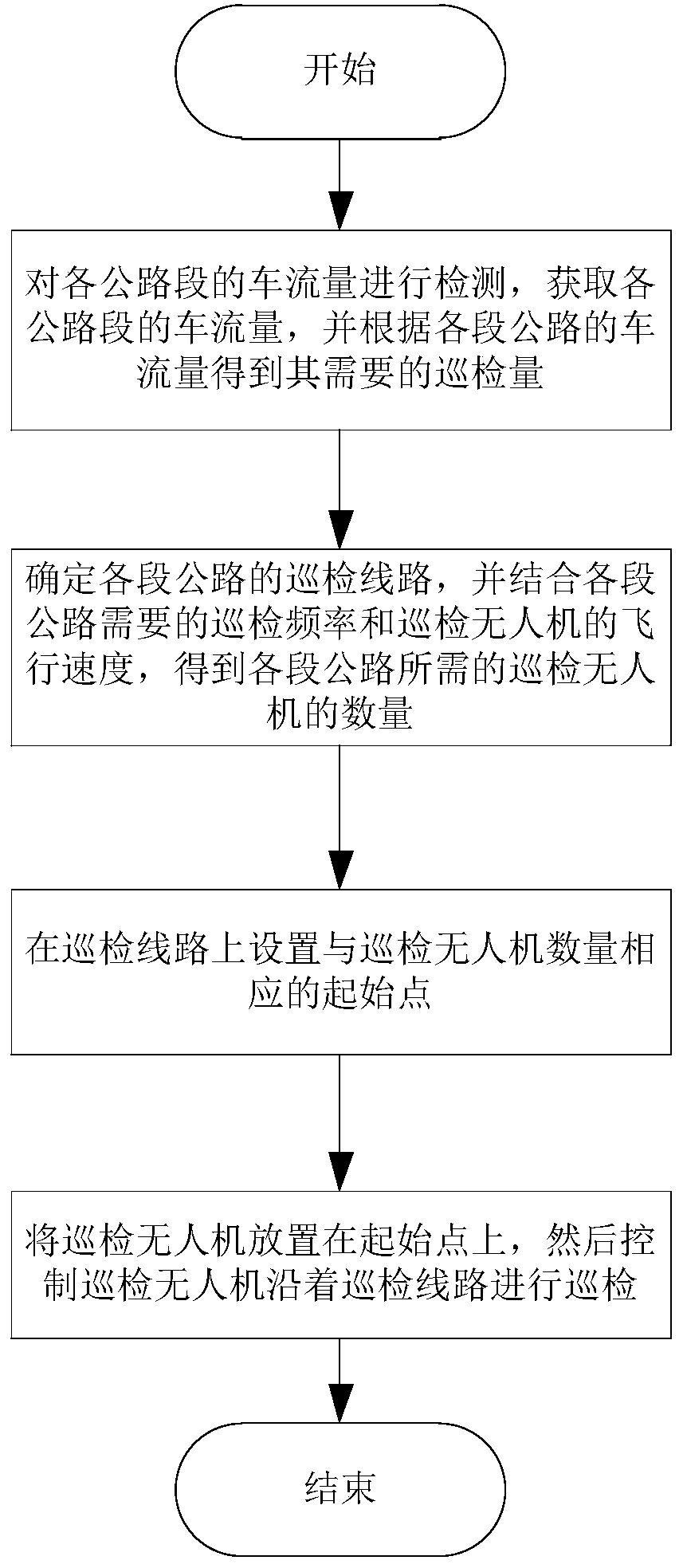

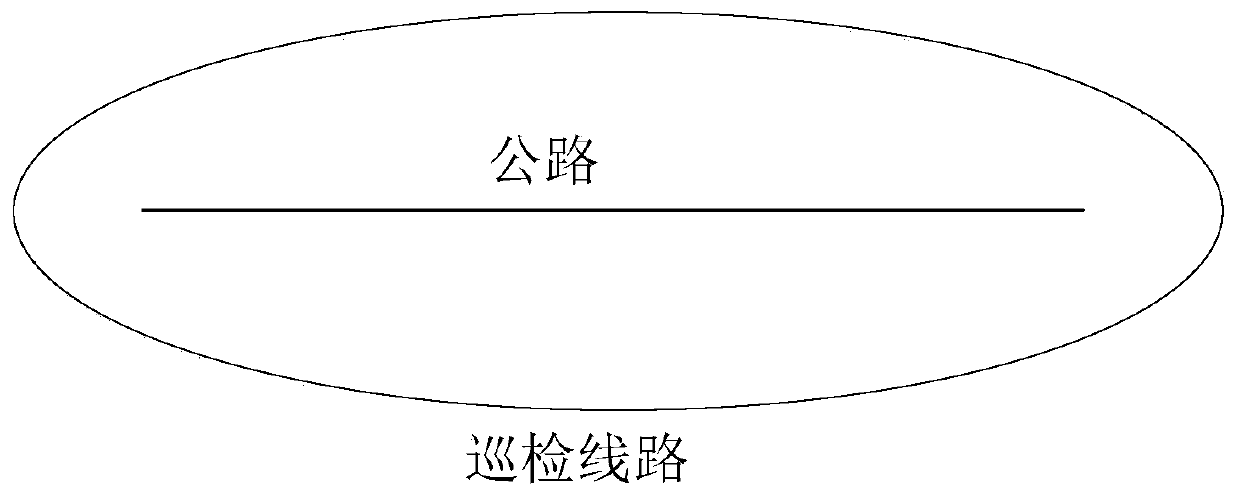

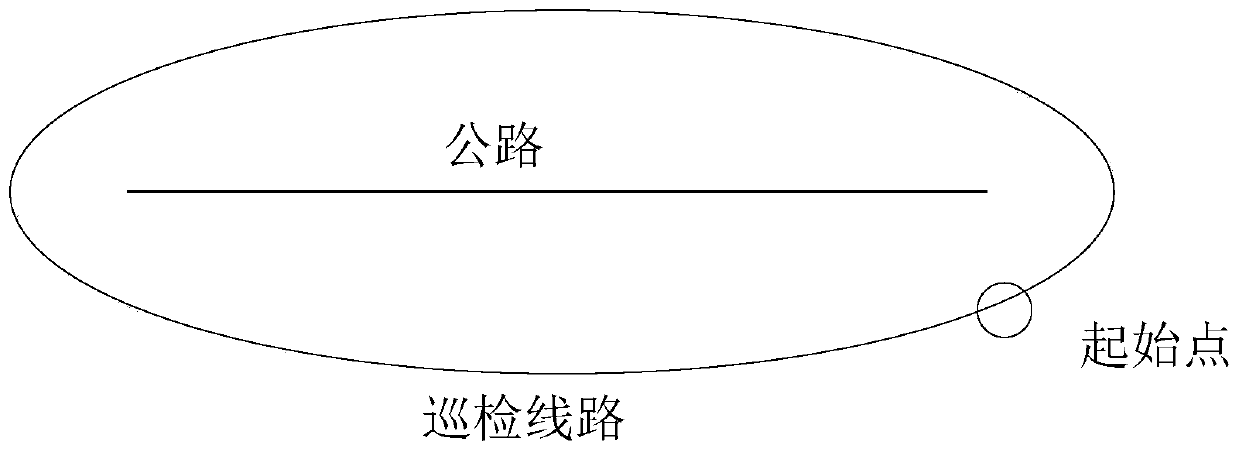

Inspection unmanned aerial vehicle control method and device for smart road

ActiveCN110825099AGuaranteed reliabilityIncrease the frequency of inspectionsAttitude controlPosition/course control in three dimensionsUncrewed vehicleTraffic flow

The invention provides an inspection unmanned aerial vehicle control method and device for a smart road, and the control method comprises the following steps: obtaining the traffic flow of each section of the road, and determining the inspection frequency required by each section of the road according to the traffic flow of each section of the road, wherein the traffic flow of the road is in positive correlation with the required inspection frequency; determining an inspection line of each inspection unmanned aerial vehicle, and combining the inspection frequency required by each section of the road and the flight speed of the inspection unmanned aerial vehicle to obtain the number of the inspection unmanned aerial vehicles required by each section of the road, wherein the inspection lineis an annular line; arranging starting points with the number corresponding to that of the inspection unmanned aerial vehicles on the inspection line, wherein the distances between every two adjacentstarting points on the inspection line are the same; and setting each inspection unmanned aerial vehicle at a starting point, and then simultaneously controlling all inspection unmanned aerial vehicles to perform inspection clockwise or anticlockwise along the inspection line. According to the technical scheme provided by the invention, the problem of relatively low routing inspection reliabilitycaused by unreasonable control on the highway routing inspection unmanned aerial vehicle in the prior art can be solved.

Owner:驻马店市公路事业发展中心

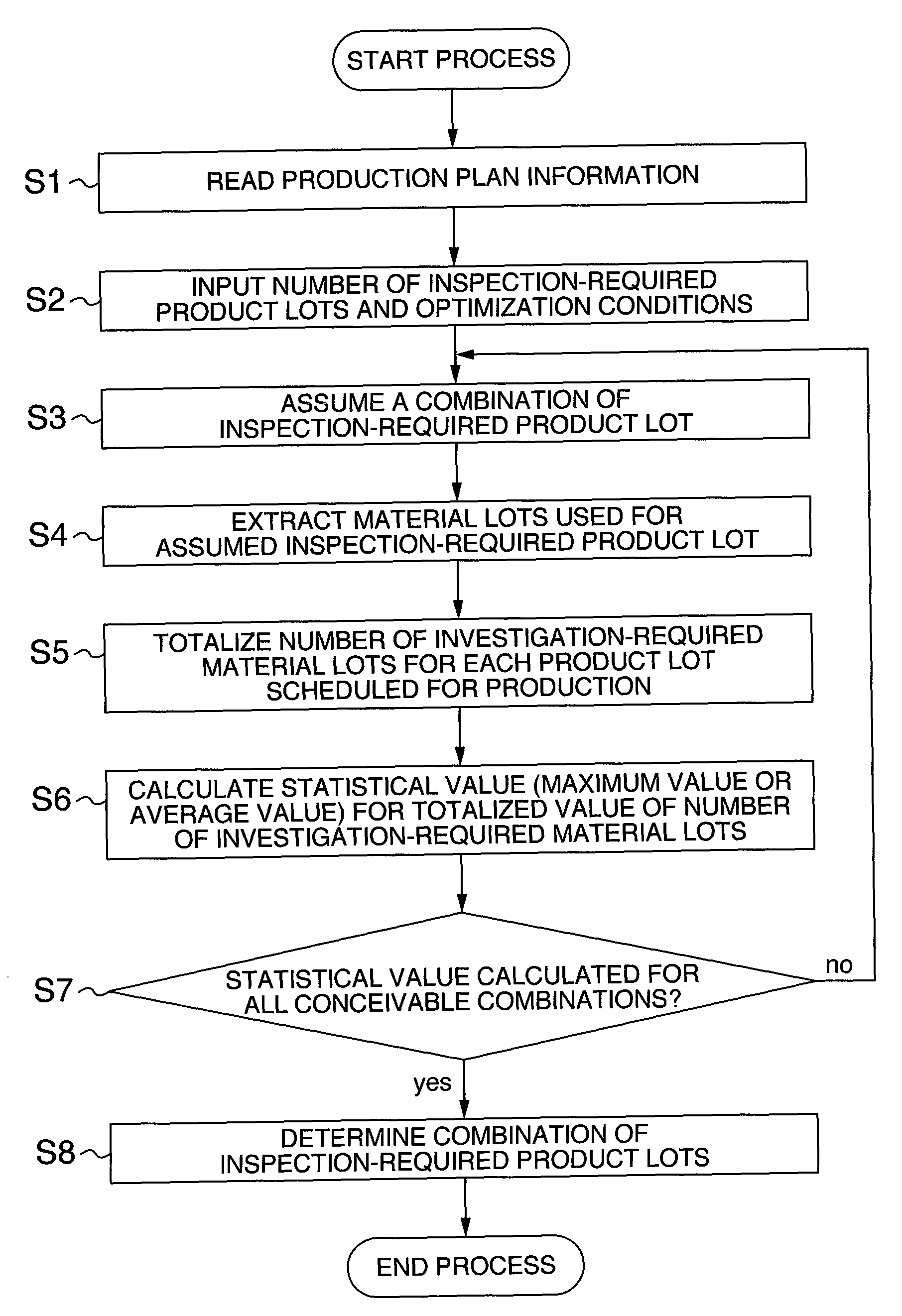

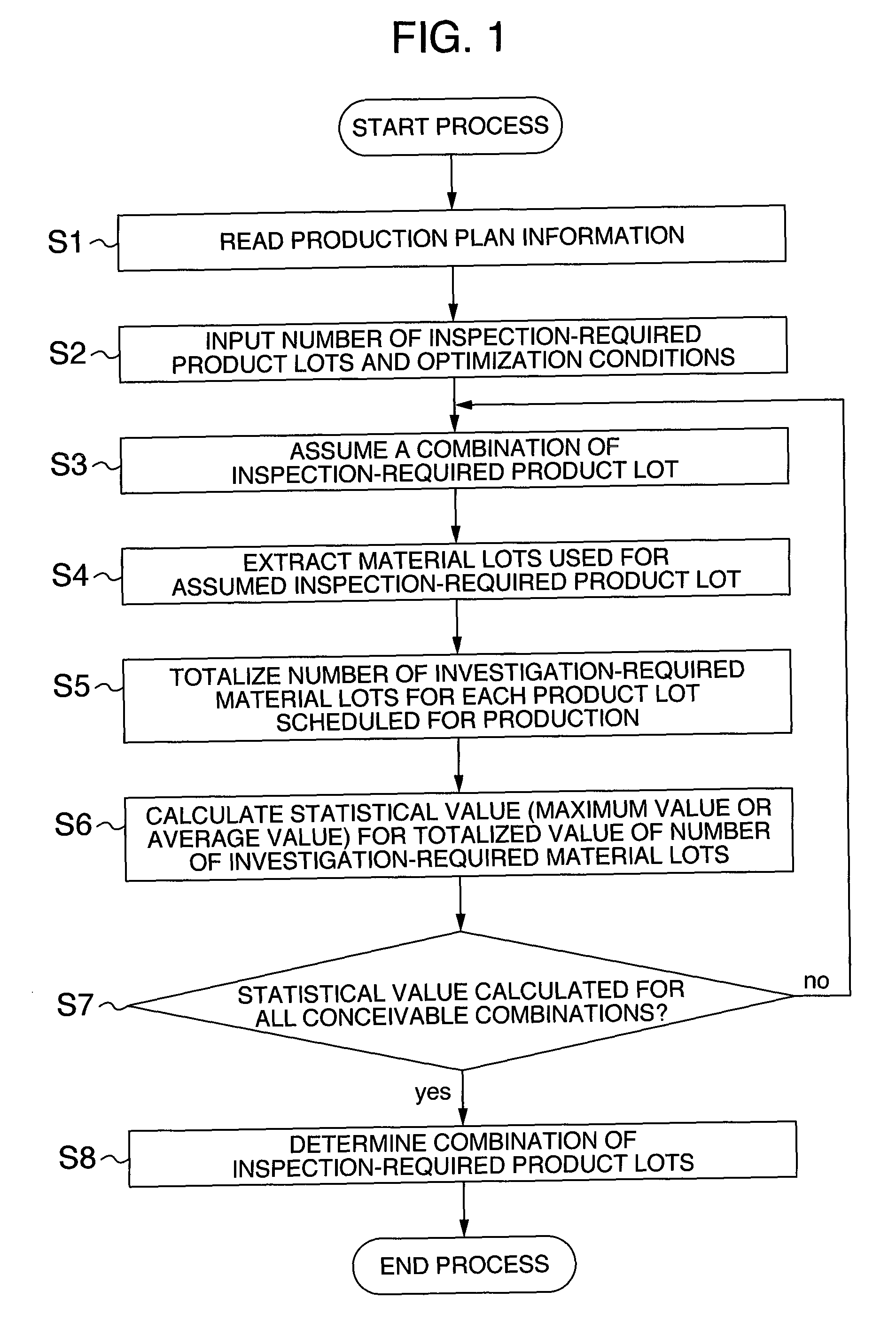

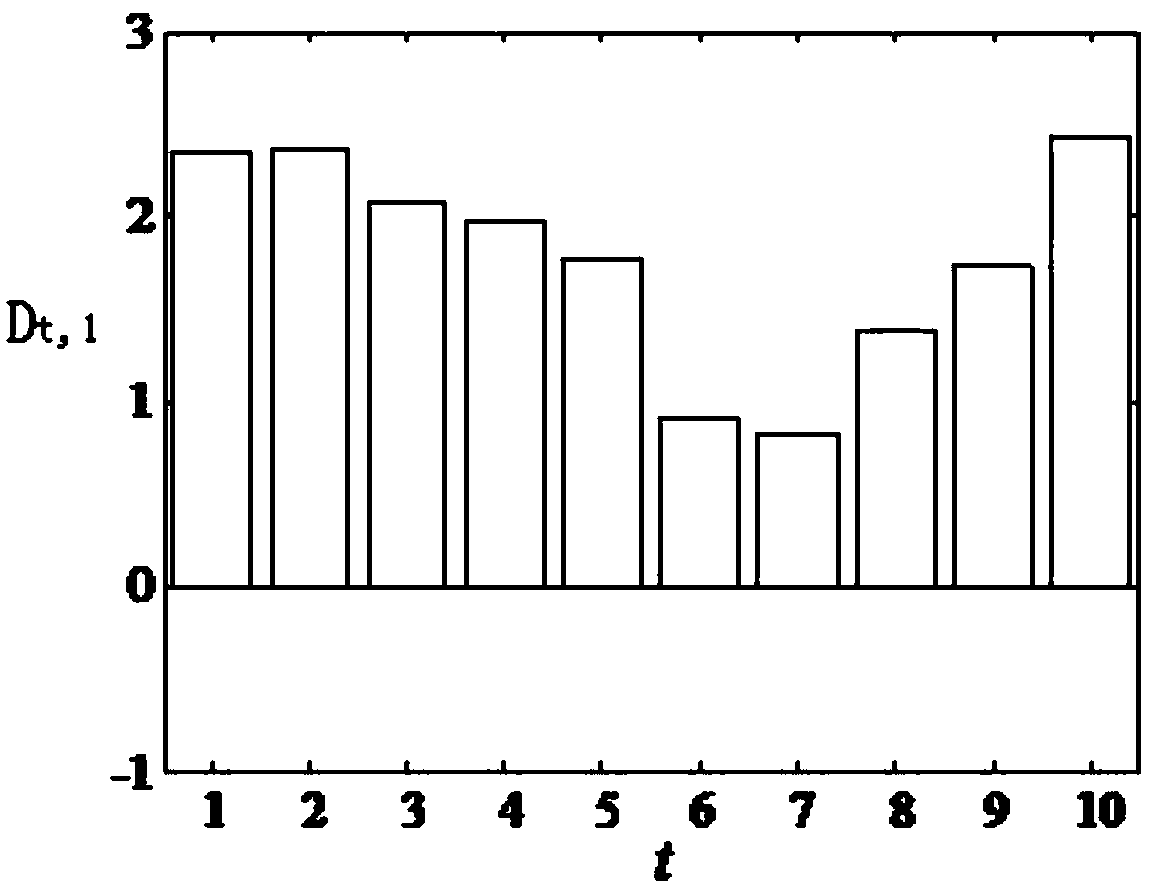

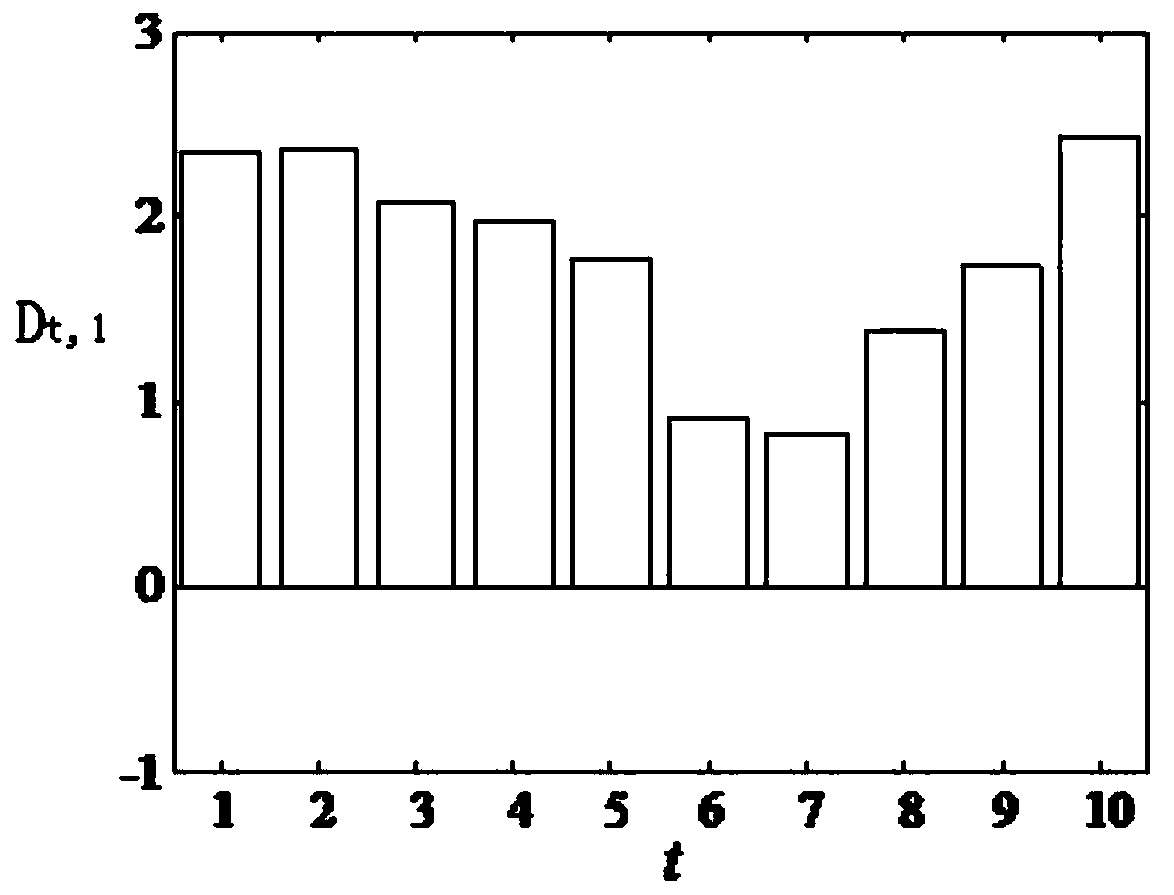

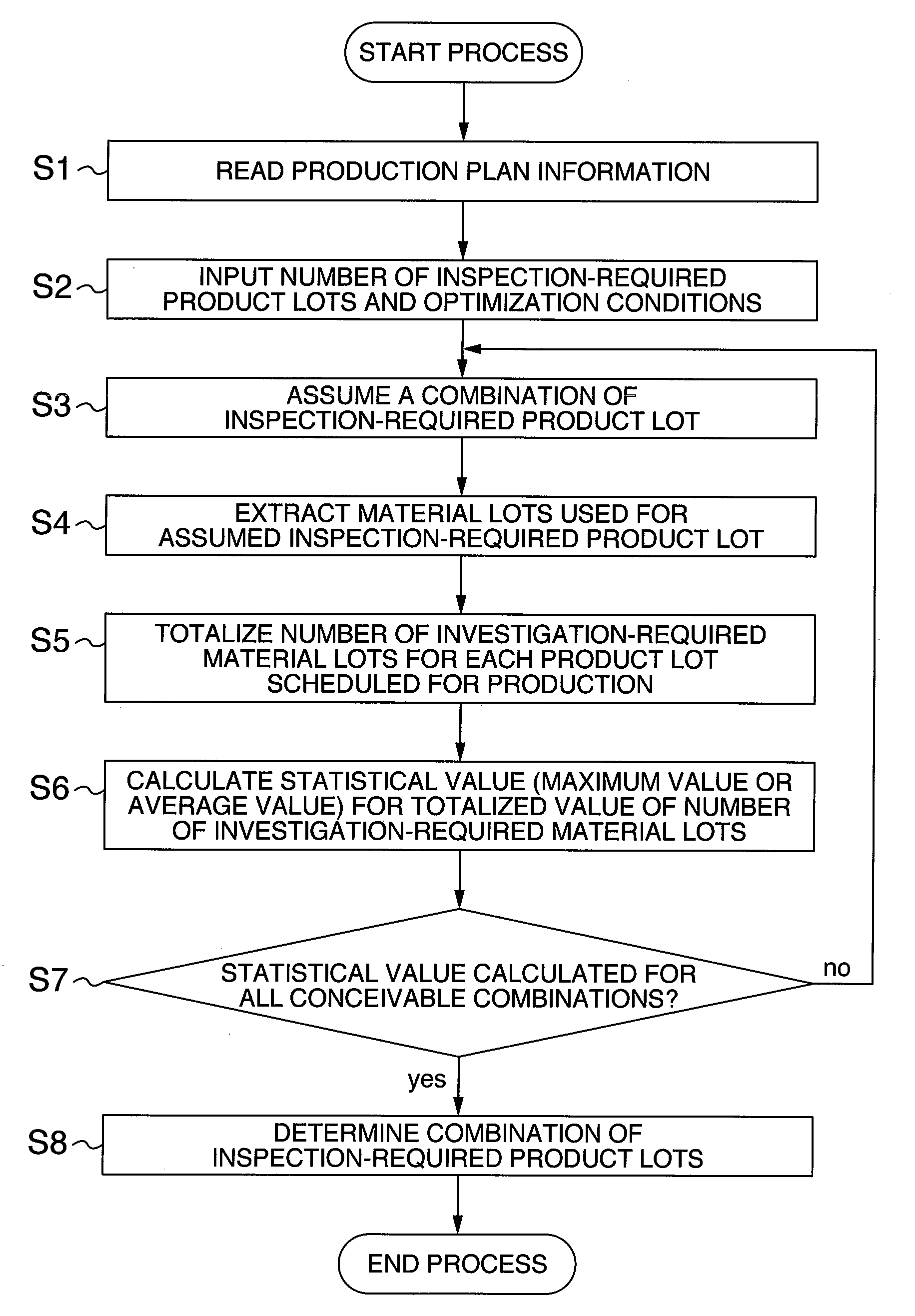

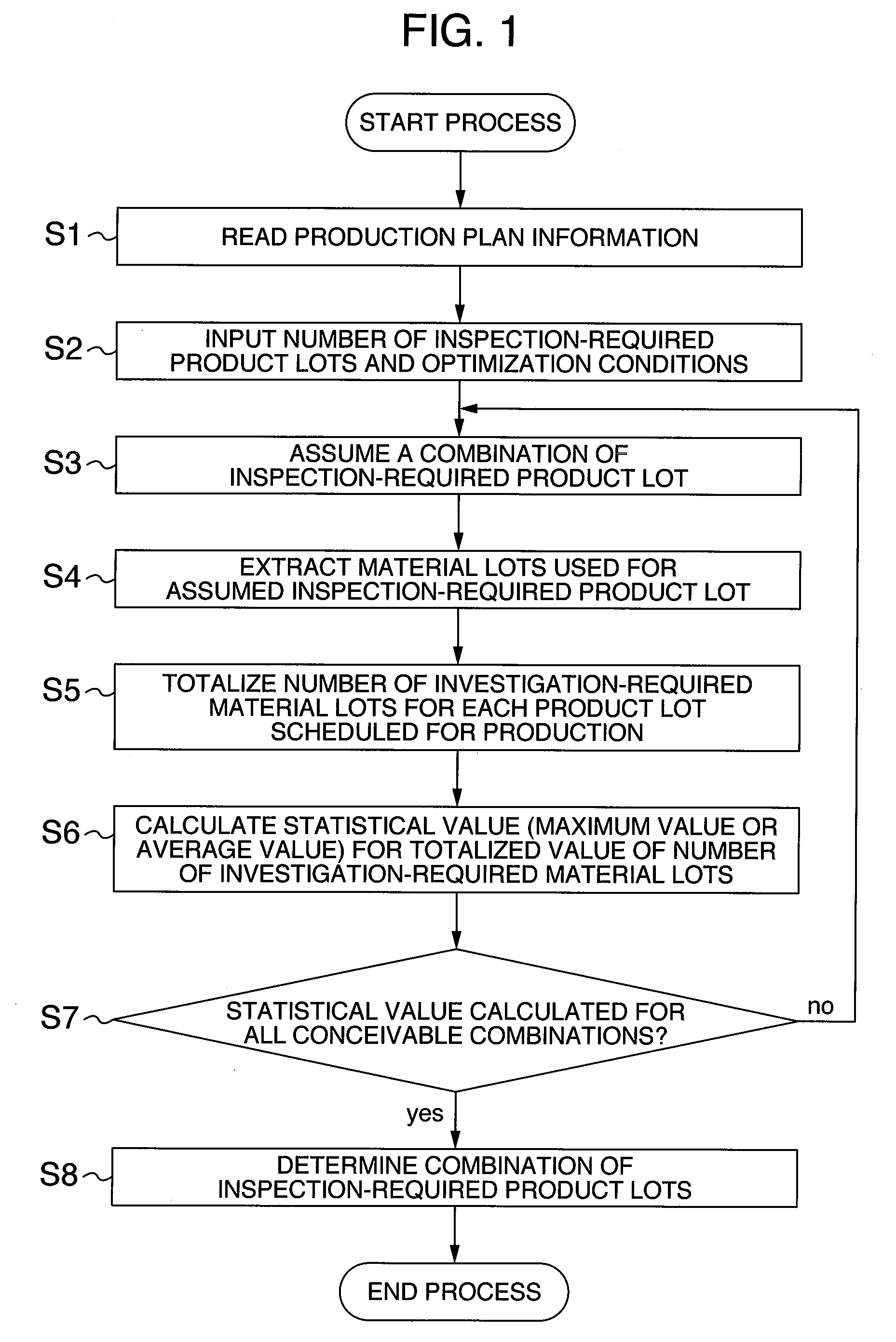

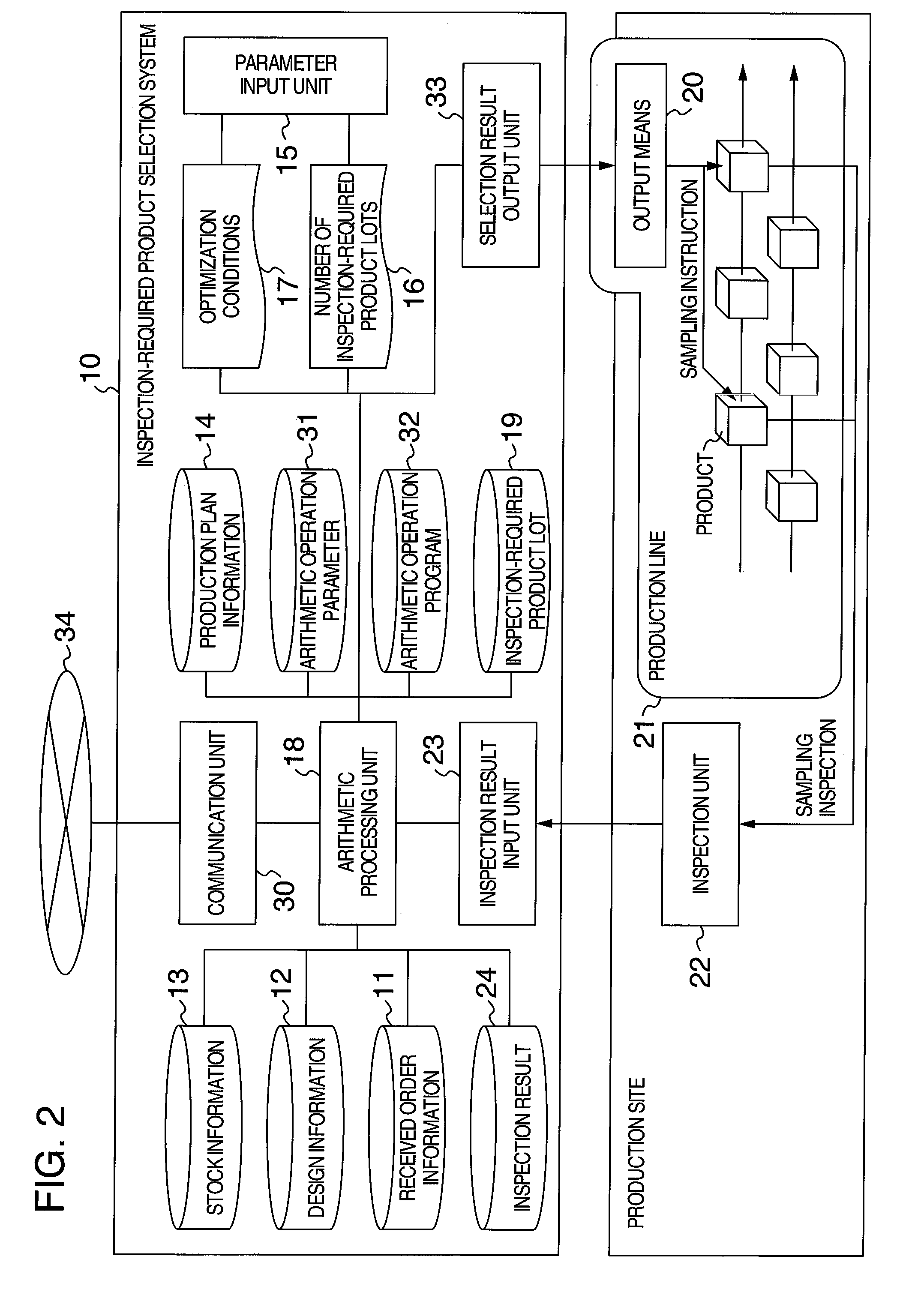

Method and program for selecting product to be inspected

InactiveUS7899567B2Reduce in quantityIncrease the frequency of inspectionsProgramme controlTotal factory controlProduct selectionEngineering

An inspection-required product selection method and program for minimizing the number of investigation steps at the time of a defect occurrence for a product placed on the market are disclosed. A combination of product lots to be inspected is assumed based on the information on the material lots used for a product lot scheduled for production for a predetermined future period and the number of the product lots inspected during the same period. The number of the material lots not included in the product lots to be inspected is totalized for each product lot, and the statistical values are calculated for all the conceivable combinations of the product lots. The combination of the product lots optimizing the statistical values is selected for inspection.

Owner:HITACHI LTD

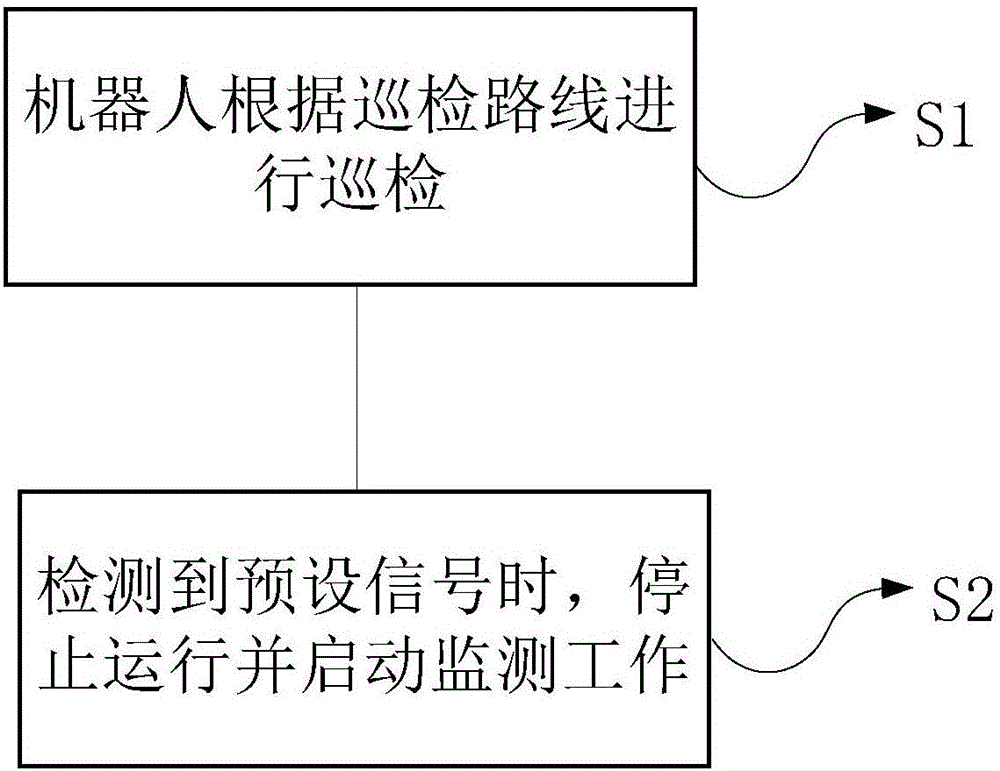

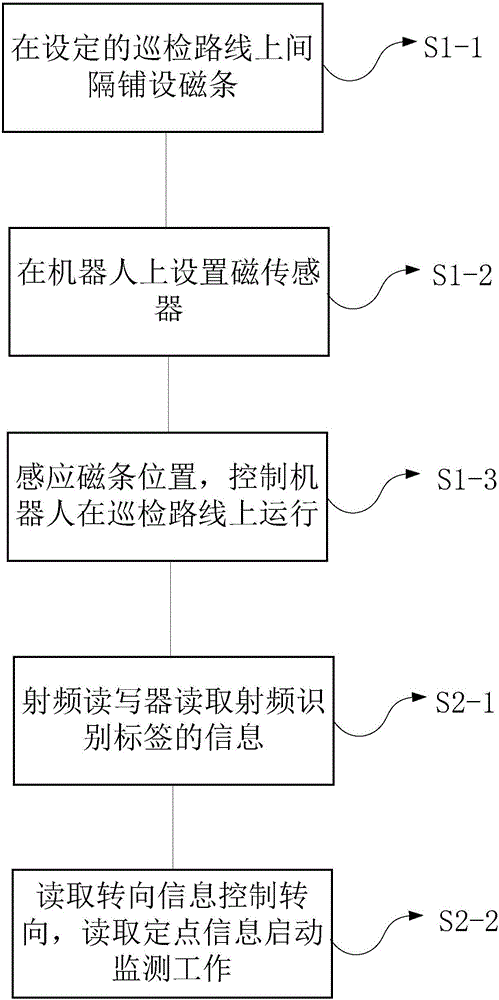

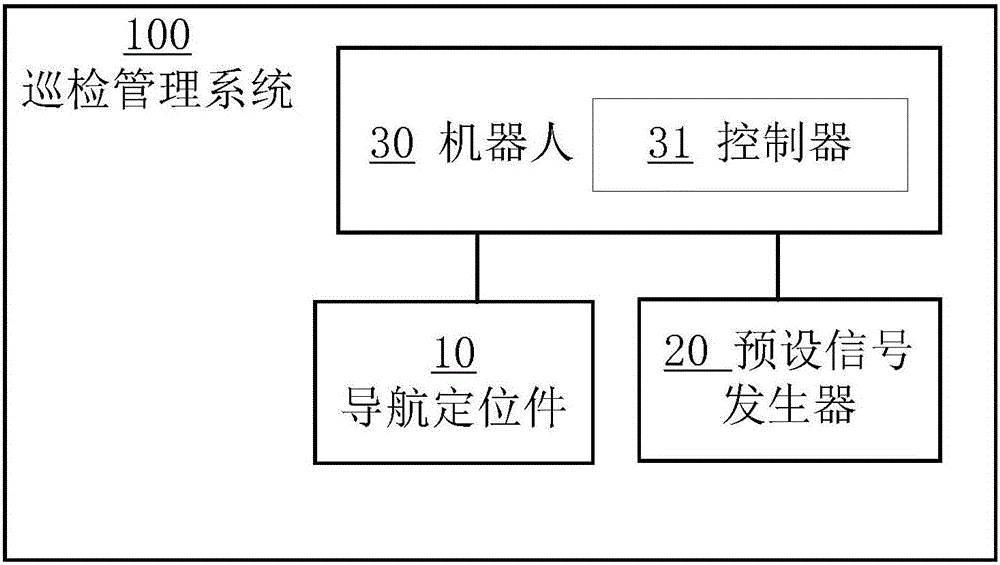

Robot polling management method and robot polling management system

PendingCN106737677AIncrease the frequency of inspectionsAccurate graspProgramme-controlled manipulatorApproaches of managementSimulation

The invention discloses a robot polling management method and a robot polling management system. The robot polling management method comprises the following steps: polling by a robot according to a polling route; and stopping running and starting monitoring operation when the robot detects a foreign preset signal. The robot polling management method and management system can reduce potential safety hazard.

Owner:重庆东电通信技术有限公司

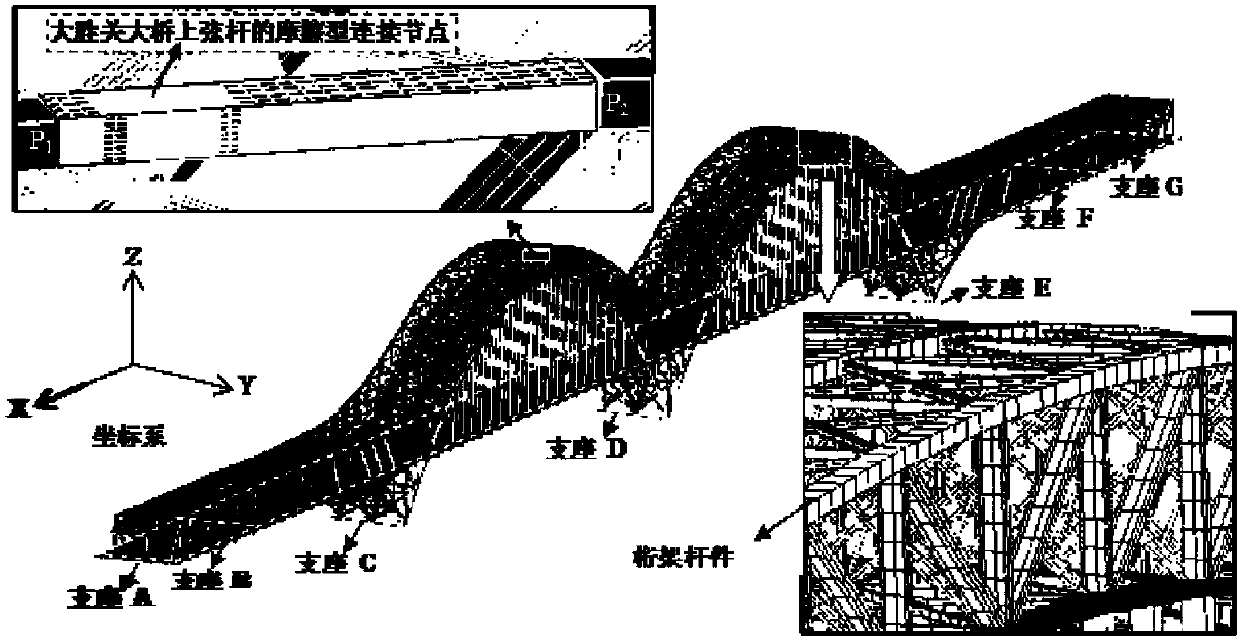

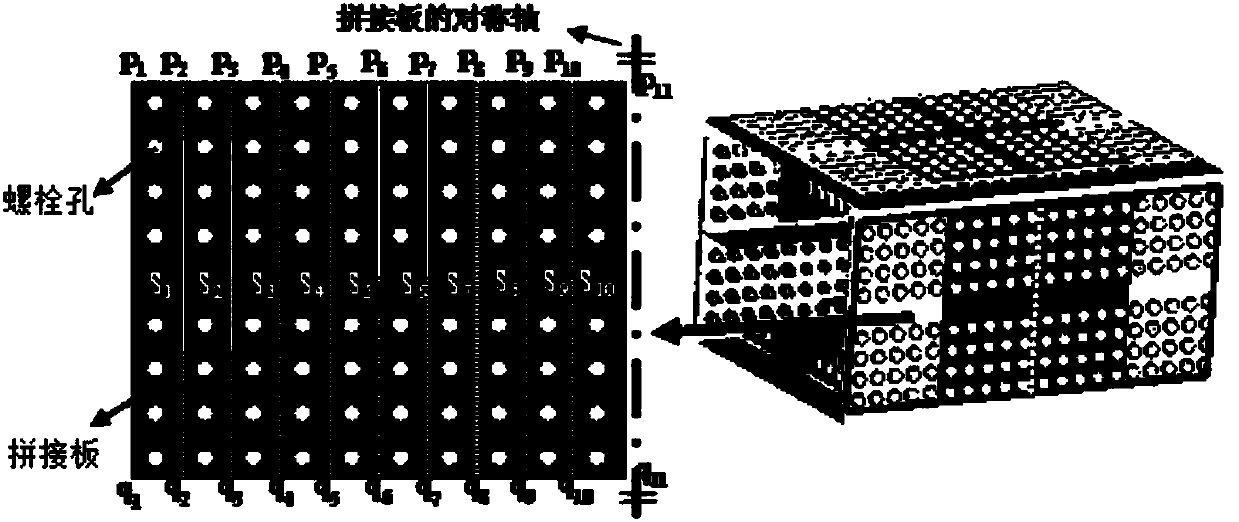

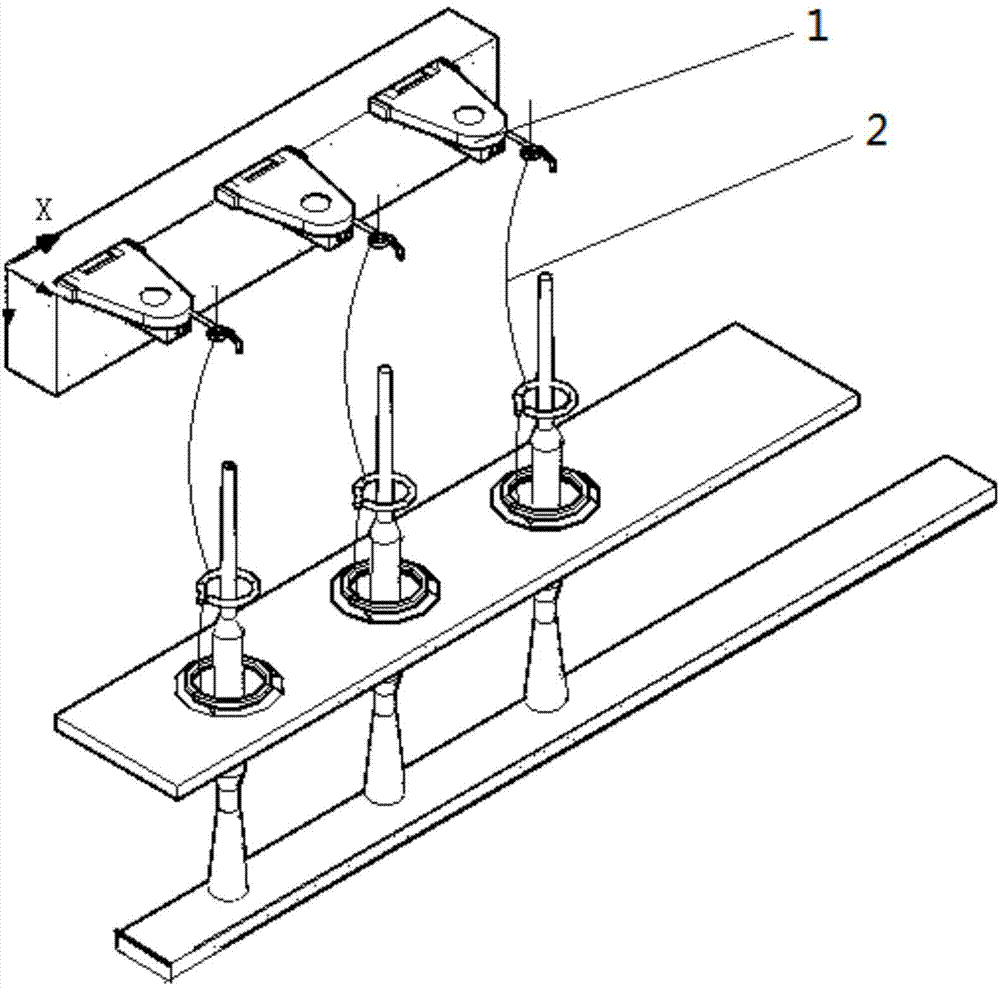

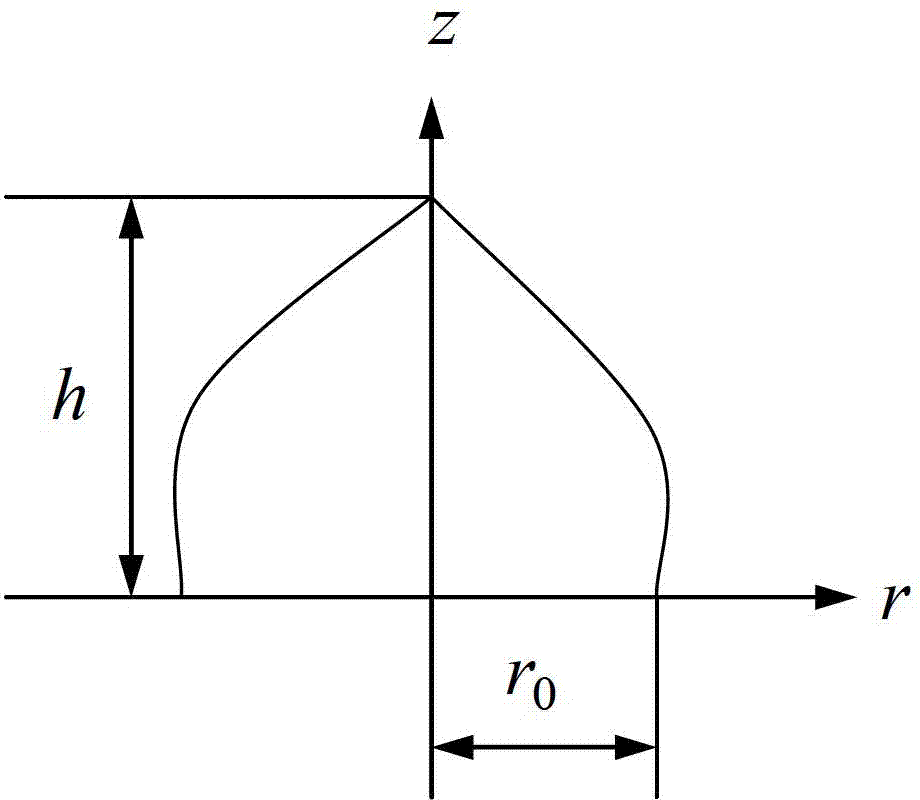

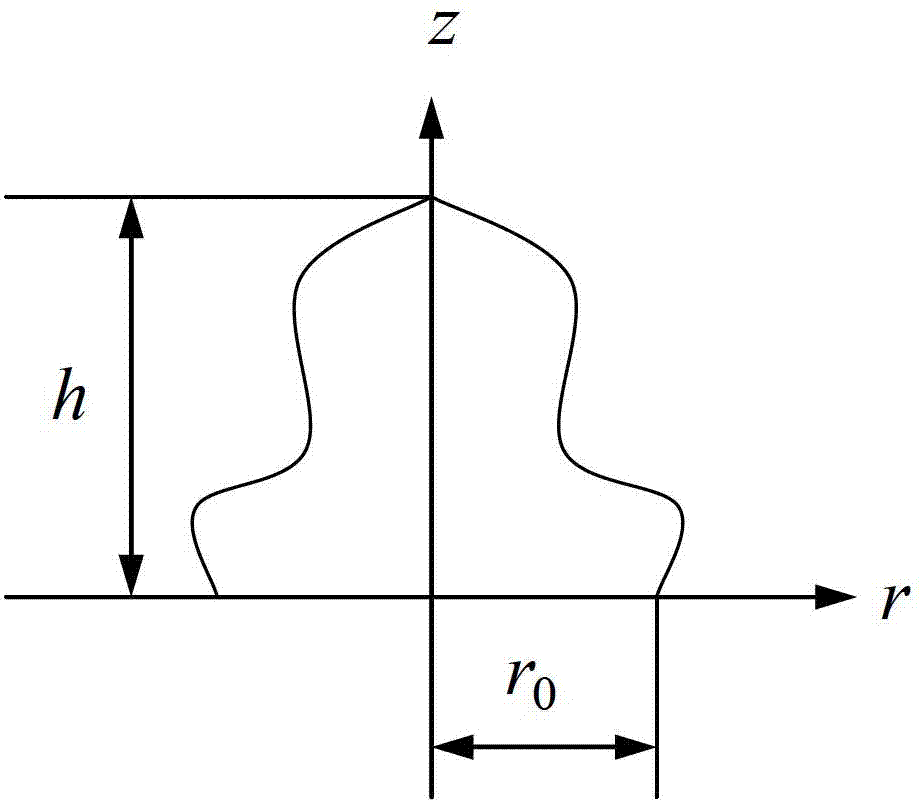

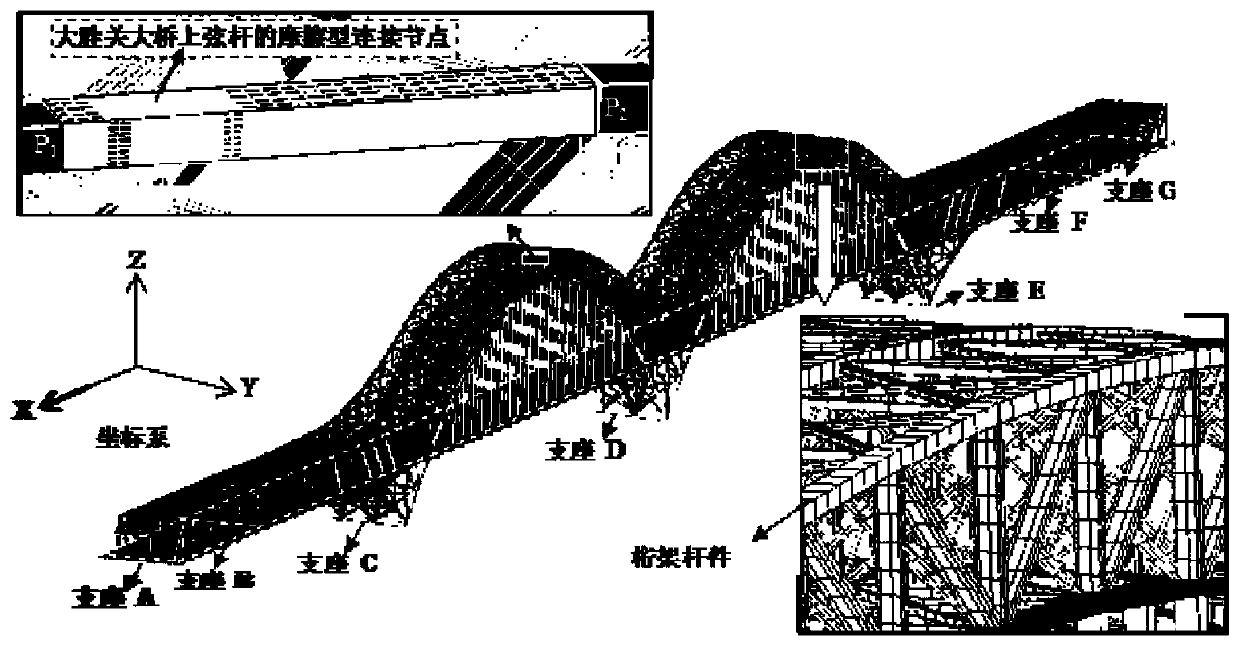

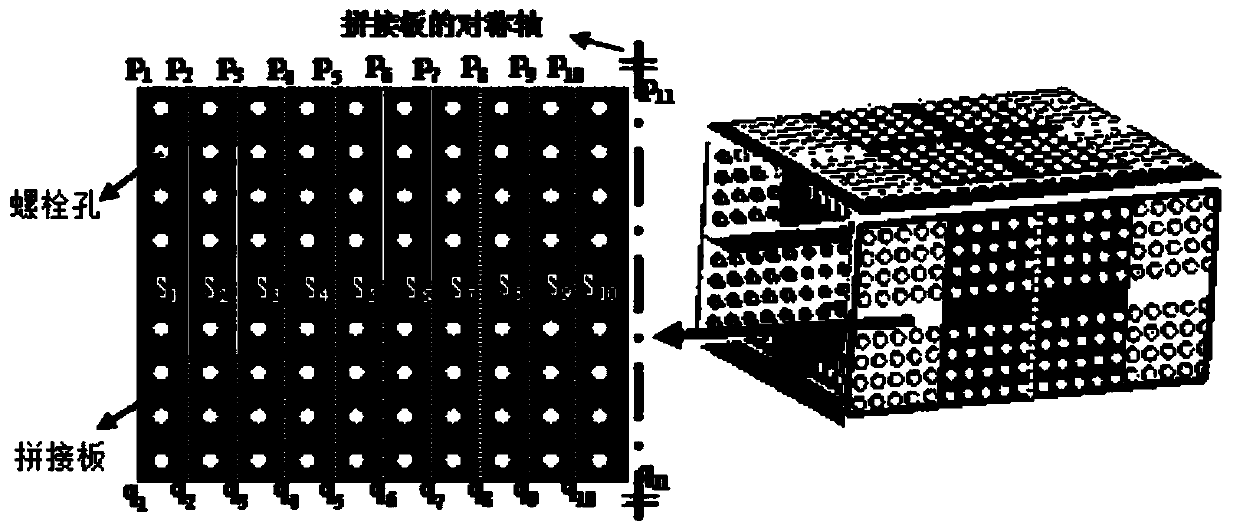

Method for recognizing looseness of friction type high-strength bolt in rod piece connection nodes

InactiveCN107588809AIncrease the frequency of inspectionsAccurate identificationMeasurement devicesEngineeringStrain sensor

The invention discloses a method for recognizing looseness of a friction type high-strength bolt in rod piece connection nodes, which comprises the steps of 10) arranging measuring points on a rod piece connection node splicing plate, and setting a temperature sensor and a fiber grating strain sensor at each measuring point; 20) building the linear change rate of the axial strain of the position of each measuring point along with the temperature field; 30) establishing a distribution curve of the linear change rate along the cross section of each rod piece; 40) performing integration on each of the established distribution curves to obtain corresponding integral values; 50) calculating a first-order difference absolute value of the adjacent integral values, and enabling the distribution curve along the rod axis direction to serve as a fundamental curve; 60) returning back to the step 20) to obtain a real-time curve of the first-order difference absolute value along the rod axis direction at the rth day; and 70) performing looseness recognition on the bolt by using the difference between the real-time curve and the fundamental curve. The looseness position of the high-strength boltcan be accurately recognized according to the recognition method disclosed by the invention.

Owner:CHINA UNIV OF MINING & TECH

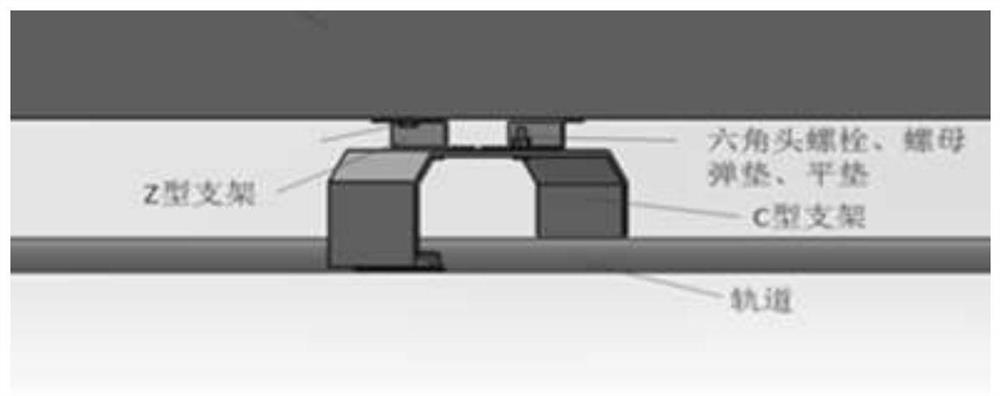

Intelligent inspection device for belt conveyor in complex industrial environment

PendingCN114146456AReduce workload and safety risksImprove inspection frequency and inspection qualitySubsonic/sonic/ultrasonic wave measurementAnalysing gaseous mixturesLeather beltPulley

An intelligent inspection device for a belt conveyor in a complex industrial environment comprises a track system and an inspection robot. The track system comprises a track and a hanging bracket assembly. The track is hoisted and fixed through the hanging bracket assembly, so that the track and a belt to be inspected are arranged in parallel; the inspection robot is hoisted on the track through a hoisting assembly and is used for completing acquisition of inspection data; the hoisting assembly is composed of pulley blocks installed on supporting legs of the inspection robot, each pulley block comprises two fixed pulleys fixedly installed on the supporting legs, rails are installed between the two fixed pulleys, and racks parallel to the rails are installed between the rails. A gear meshed with the rack is arranged on the inspection robot, and the gear is meshed with the rack to drive the two fixed pulleys on each supporting leg to rotate along the track and move forwards under power driving of the inspection robot.

Owner:CAPITAL AEROSPACE MACHINERY

A control method and device for inspection drones for smart highways

ActiveCN110825099BGuaranteed reliabilityIncrease the frequency of inspectionsAttitude controlPosition/course control in three dimensionsUncrewed vehicleTraffic flow

The invention provides an inspection unmanned aerial vehicle control method and device for a smart road, and the control method comprises the following steps: obtaining the traffic flow of each section of the road, and determining the inspection frequency required by each section of the road according to the traffic flow of each section of the road, wherein the traffic flow of the road is in positive correlation with the required inspection frequency; determining an inspection line of each inspection unmanned aerial vehicle, and combining the inspection frequency required by each section of the road and the flight speed of the inspection unmanned aerial vehicle to obtain the number of the inspection unmanned aerial vehicles required by each section of the road, wherein the inspection lineis an annular line; arranging starting points with the number corresponding to that of the inspection unmanned aerial vehicles on the inspection line, wherein the distances between every two adjacentstarting points on the inspection line are the same; and setting each inspection unmanned aerial vehicle at a starting point, and then simultaneously controlling all inspection unmanned aerial vehicles to perform inspection clockwise or anticlockwise along the inspection line. According to the technical scheme provided by the invention, the problem of relatively low routing inspection reliabilitycaused by unreasonable control on the highway routing inspection unmanned aerial vehicle in the prior art can be solved.

Owner:驻马店市公路事业发展中心

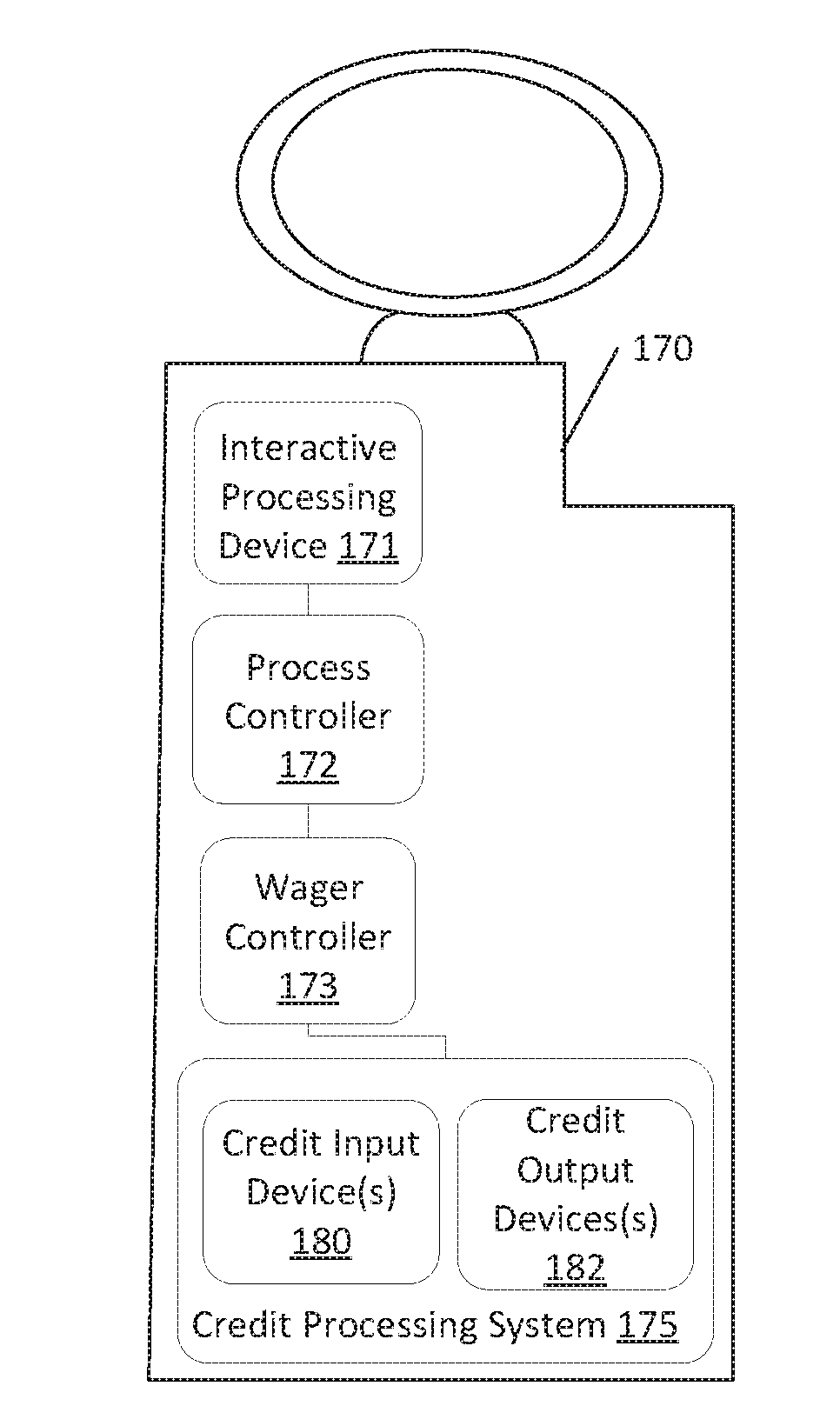

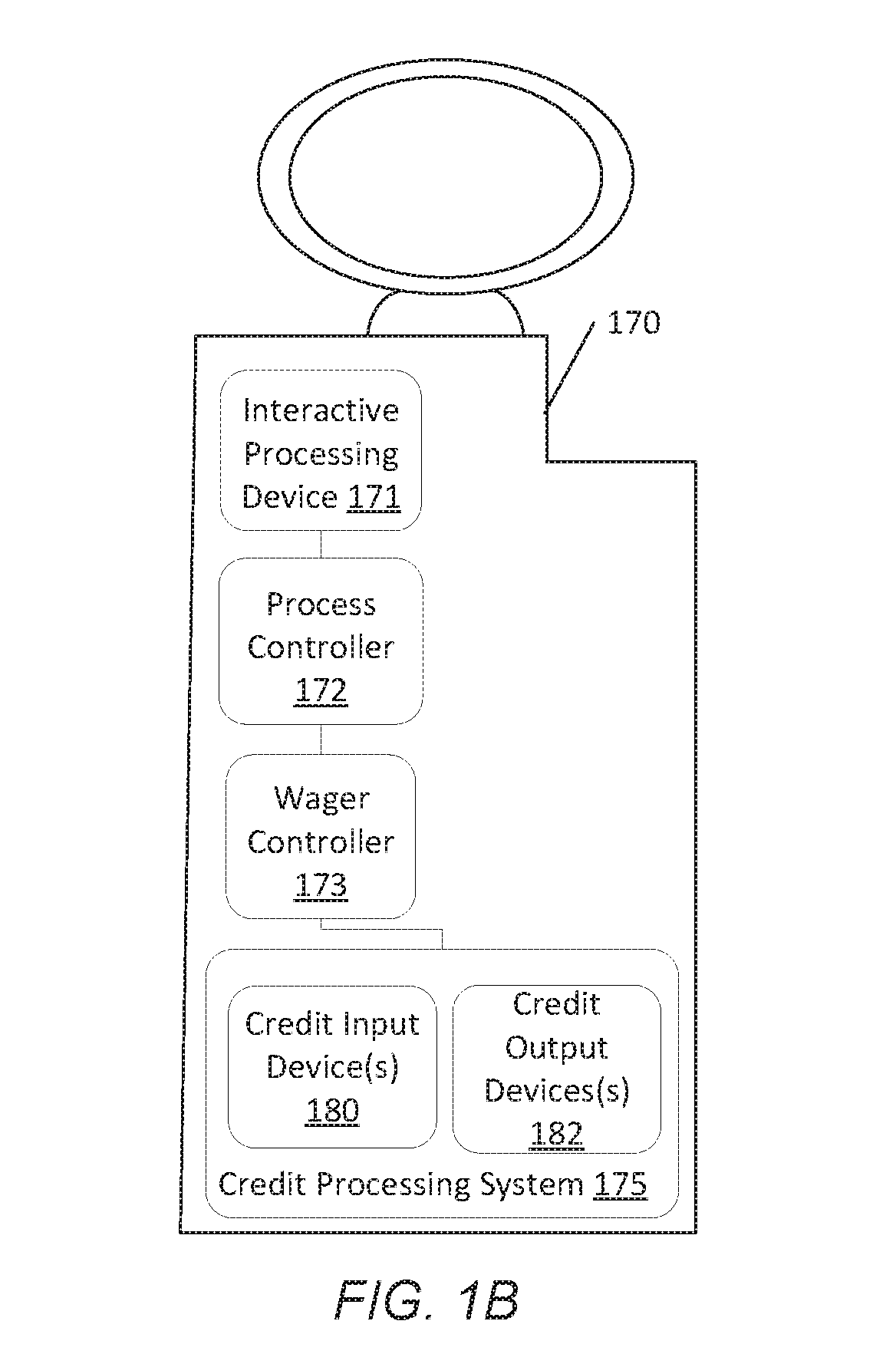

Gwc production monitoring interleaved wagering system

InactiveUS20190080558A1Convenient operation and managementEasy to operateApparatus for meter-controlled dispensingApplication softwareHuman–computer interaction

An electronic gaming machine using a game world credit monitoring module, an interactive processing device, a process controller, and a wager controller to provide an interactive application that triggers wagers on the wager controller based on user interactions within the interactive application and allows the electronic gaming machine to make adjustments to the interactive application difficulty level to achieve a desired RTP based on game world credit generation within the interactive application.

Owner:GAMBLIT GAMING

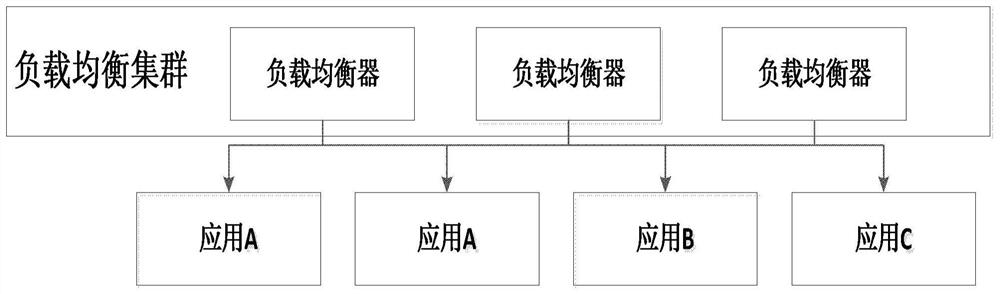

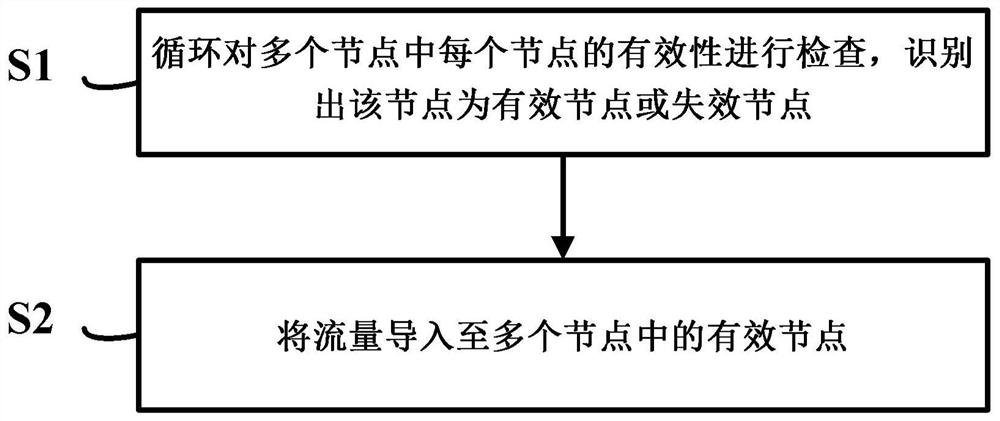

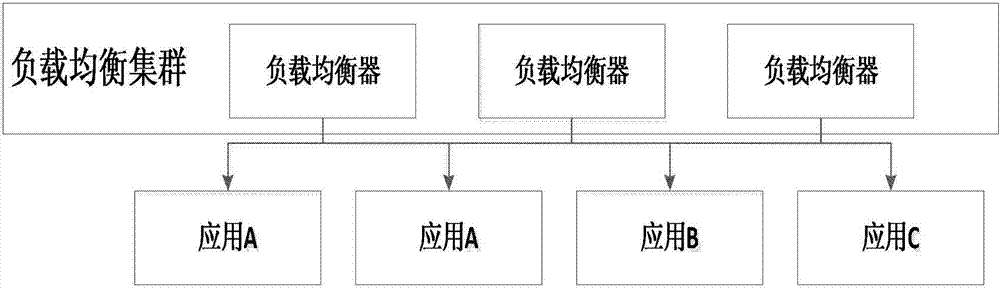

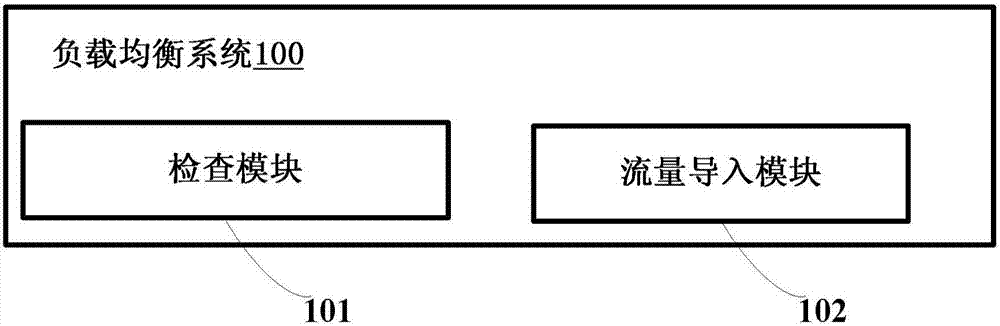

Load balancing method, system, electronic device and computer-readable storage medium

ActiveCN107453938BReduce inspection frequencyReduce resource consumptionData switching networksReliability engineeringReal-time computing

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

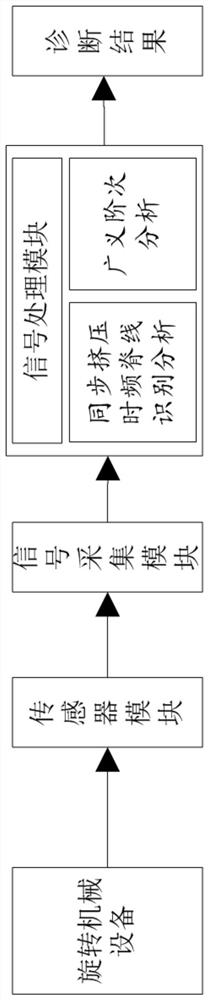

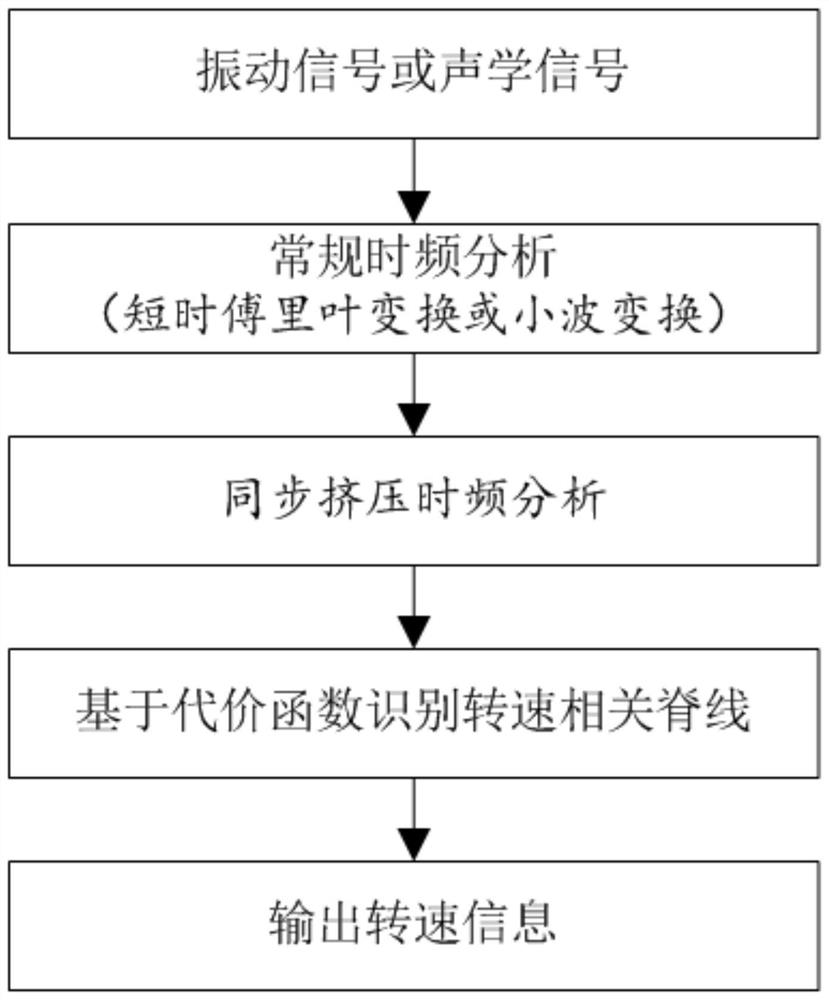

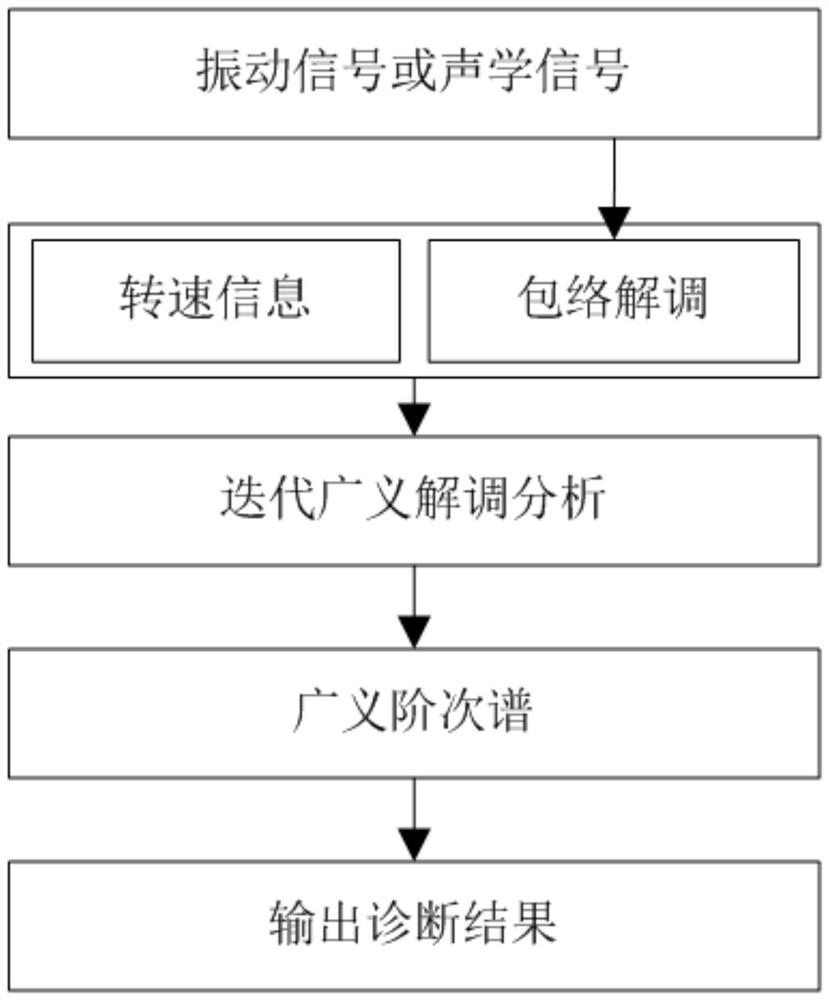

Automatic diagnosis system and method for rotating mechanical equipment

ActiveCN108760294BRealize automatic diagnosisLow costMachine part testingControl engineeringMechanical equipment

The invention belongs to the mechanical equipment diagnosis technical field and relates to a rotating mechanical equipment automatic diagnosis system and method. The method has the advantages of low cost, high stability, convenient installation and use, convenient maintenance, high precision and the like. With the rotating mechanical equipment automatic diagnosis system and method adopted, the automatic diagnosis of the health state of rotating mechanical equipment under different rotational speed conditions can be realized, specific failure modes can be diagnosed, so that trouble-shooting iscarried out in a targeted manner; and equipment state characteristics in a time-frequency joint domain which are included in equipment dynamic signals can be displayed with higher precision, so that adiagnosis technology is easy to operate. The rotating mechanical equipment automatic diagnosis system and method can remotely monitor the operation of the rotating mechanical equipment and significantly reduce inspection costs and improve inspection frequency.

Owner:SUZHOU UNIV

bp bridge safety inspection vehicle and method for obtaining bridge surface appearance

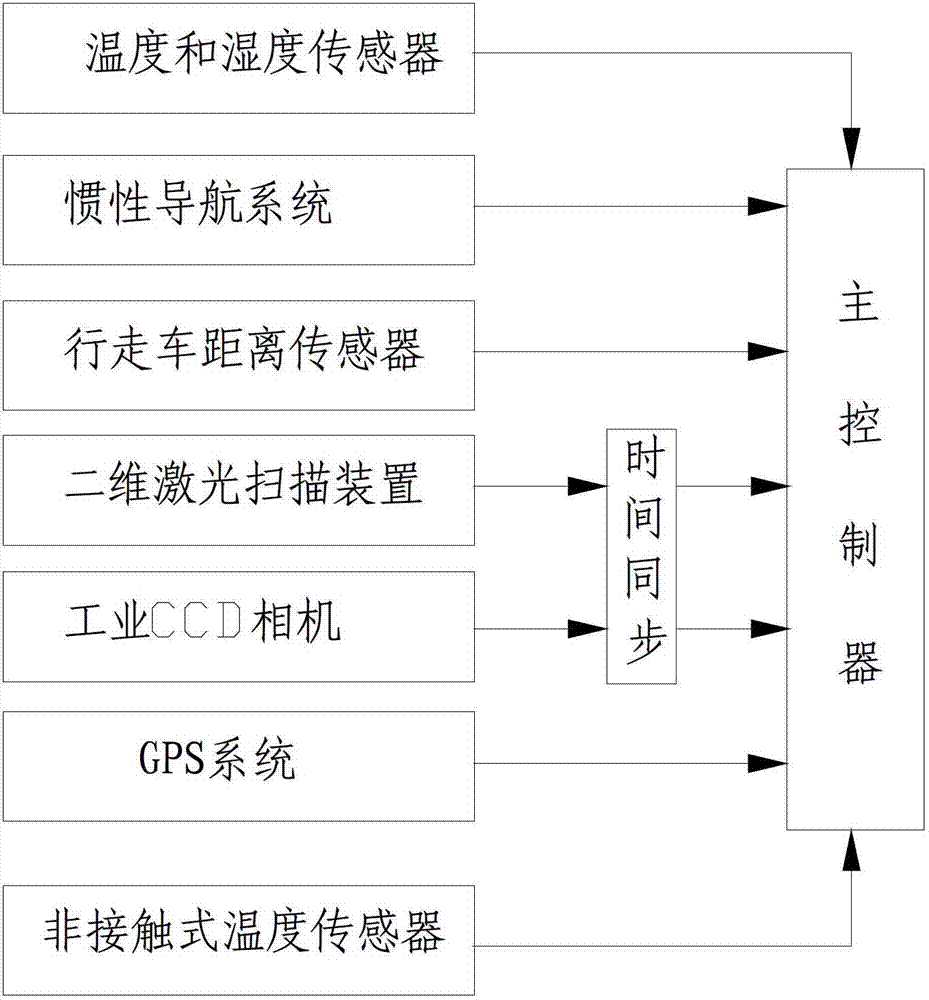

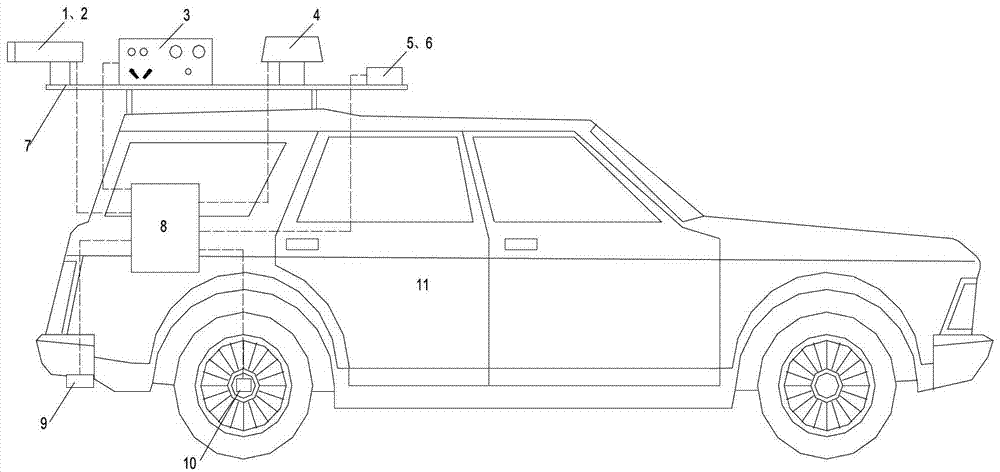

ActiveCN103266559BGuaranteed operational safetyPrevent accidental collapse accidentsBridge structural detailsLaser scanningPhysiognomy

The invention discloses a BP bridge safety inspection vehicle and a method for obtaining a bridge surface physiognomy. Equipment comprises a walking vehicle and a bridge physiognomy collecting system which is loaded on the walking vehicle, wherein the bridge physiognomy collecting system at least comprises a two-dimensional laser scanning device, an industrial CCD camera, a GPS system, an inertial navigation system and a main controller. According to the BP bridge safety inspection vehicle and the method for obtaining the bridge surface physiognomy, three-dimensional geometric shapes and texture image data of the surface of the outer contour of a visible bridge can be rapidly obtained in a high-precision mode, when the BP bridge safety inspection vehicle and the method for obtaining the bridge surface physiognomy are used, current safety conditions of a bridge structure are judged through comprehensive comparative analysis on history data obtained by the BP bridge safety inspection vehicle, therefore, operation safety of the bridge is guaranteed, bridge accidental collapse accidents are eradicated, a traditional bridge inspection method focusing on manual visual inspection is promoted to develop in an automatic, efficient, standardized and precise direction, and the BP bridge safety inspection vehicle and the method for obtaining the bridge surface physiognomy can also be used for conducting regular bridge safety check in an efficient, economical, practical and accurate mode.

Owner:CHONGQING JIAOTONG UNIVERSITY

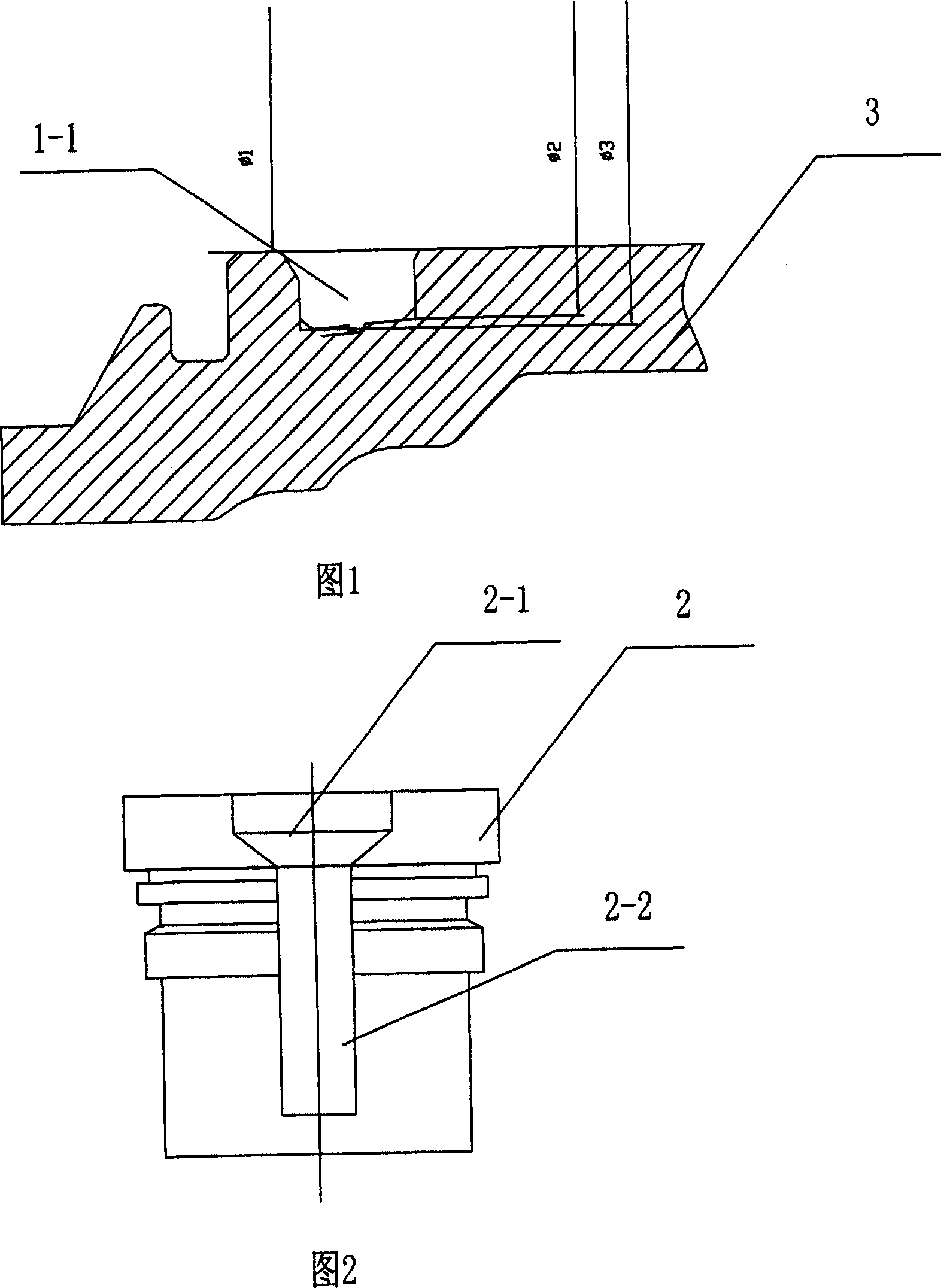

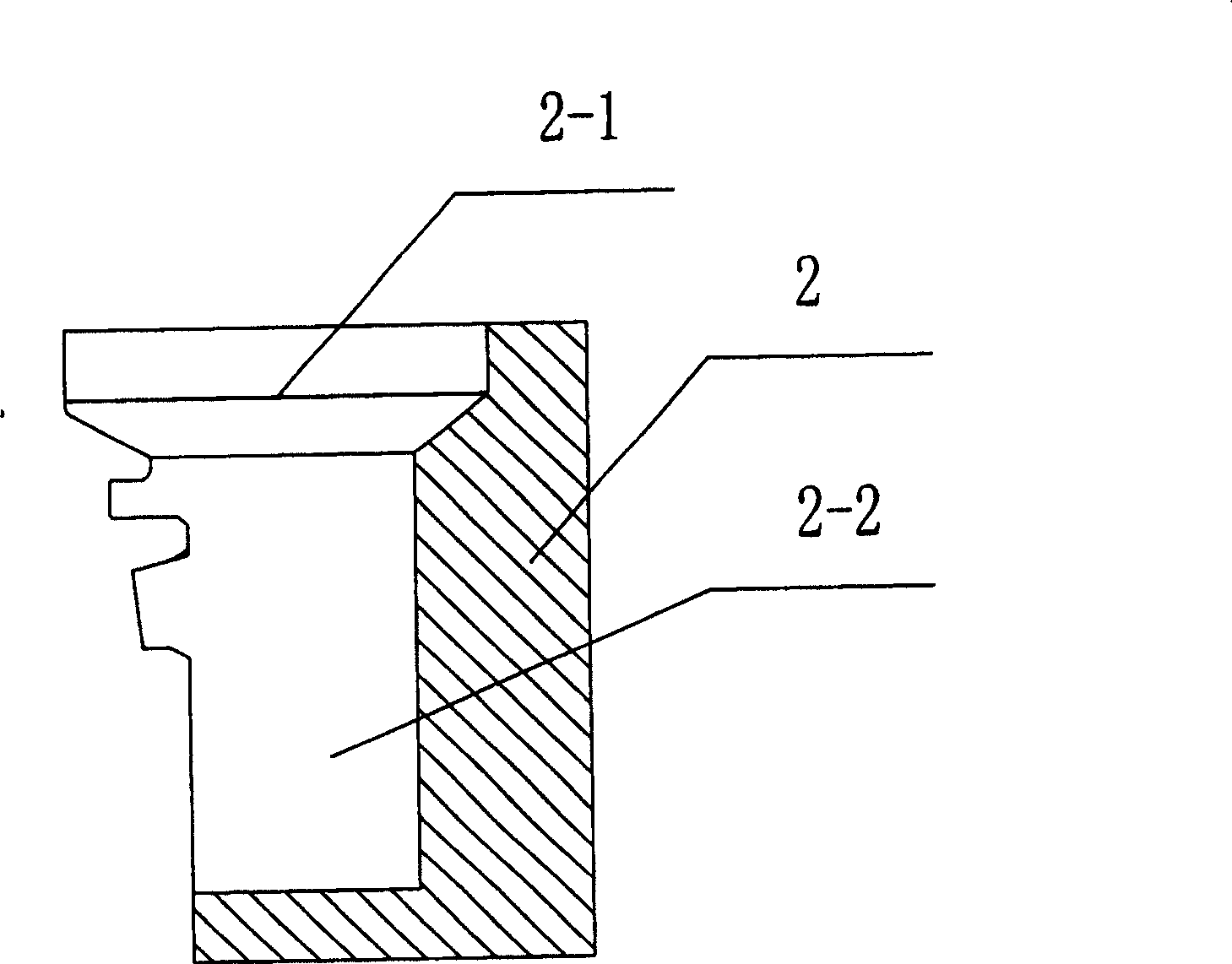

Non destructive rectangle groove dimension detecting method

The invention relates to a size detecting method of non-destructive rectangular groove which includes following steps: producing a pouring model based on shape of wall of inner cavity and outer surface of pouring model, the pouring model includes pouring mouth and pouring cavity which are connected, the pouring cavity is cavity whose side face is open, opening of the cavity is on outer surface of pouring model matched with wall of inner cavity; the pouring model abuts on wall of inner cavity, the fusible metal is poured into pouring cavity from pouring mouth, when it is cooled, metal block whose shape is the same as rectangular groove is formed, the metal block is projected under projecting apparatus for detecting size. The benefit effects of the invention are: the detecting method of the invention not only destroy product, but also increase efficiency, decrease period of detecting, increase frequency, guarantee quality of product.

Owner:WANXIANG +1

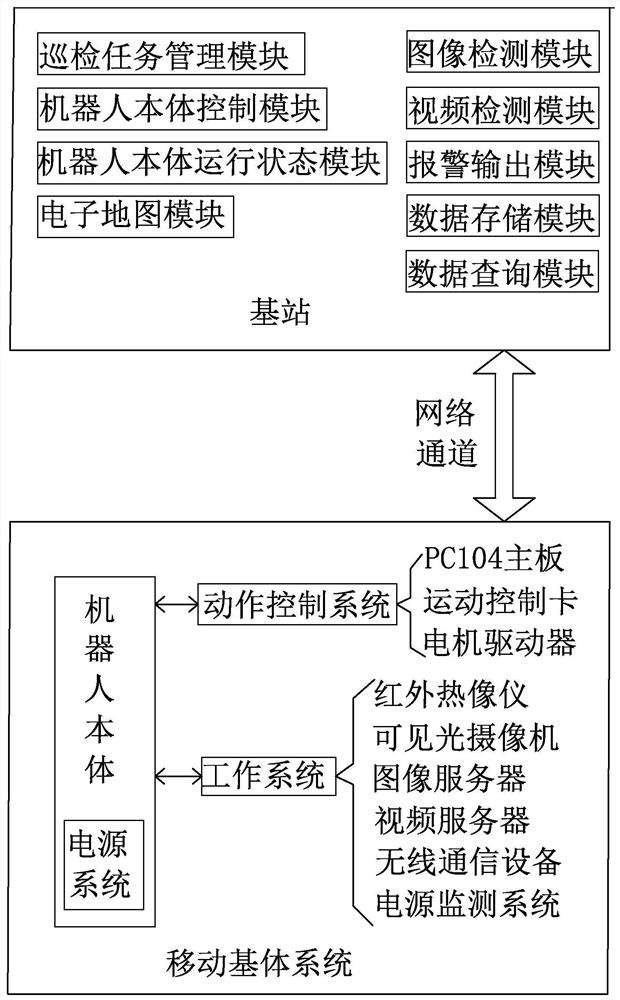

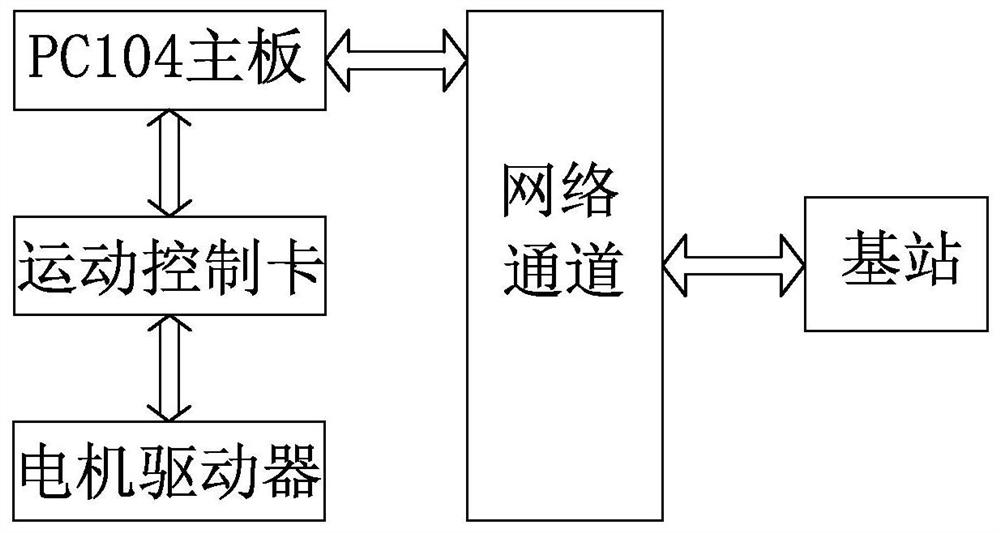

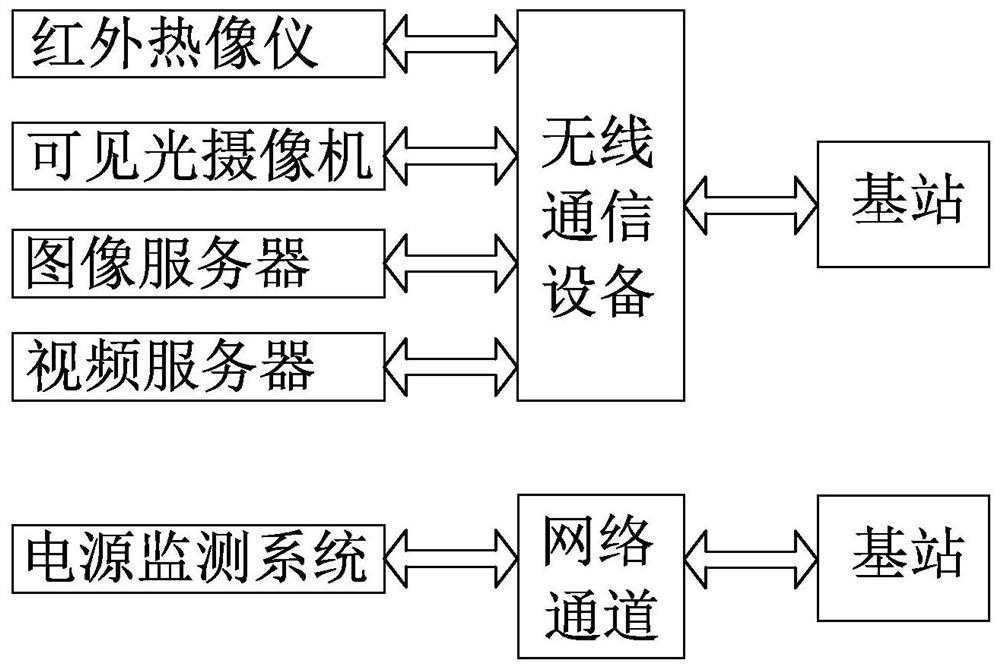

A substation intelligent inspection system

ActiveCN109861387BImprove immediacyImprove reliabilityCircuit arrangementsNavigation instrumentsControl systemEmbedded system

The invention discloses an intelligent inspection system for a substation, which includes a mobile base system, a network channel and a base station. The mobile base system is connected to the base station by using the network channel; the mobile base system includes a robot body and a The motion control system and the working system on the robot body; the motion control system receives the motion commands issued by the base station, and performs motion control on the robot body; the working system receives the work commands issued by the base station, And drive the robot body to detect the substation, and the working system transmits the detection information to the base station through the network channel. The inspection system greatly reduces inspection labor costs, increases inspection frequency, and improves the immediacy, reliability, authenticity and accuracy of inspection result data.

Owner:HANGZHOU SHENHAO TECH

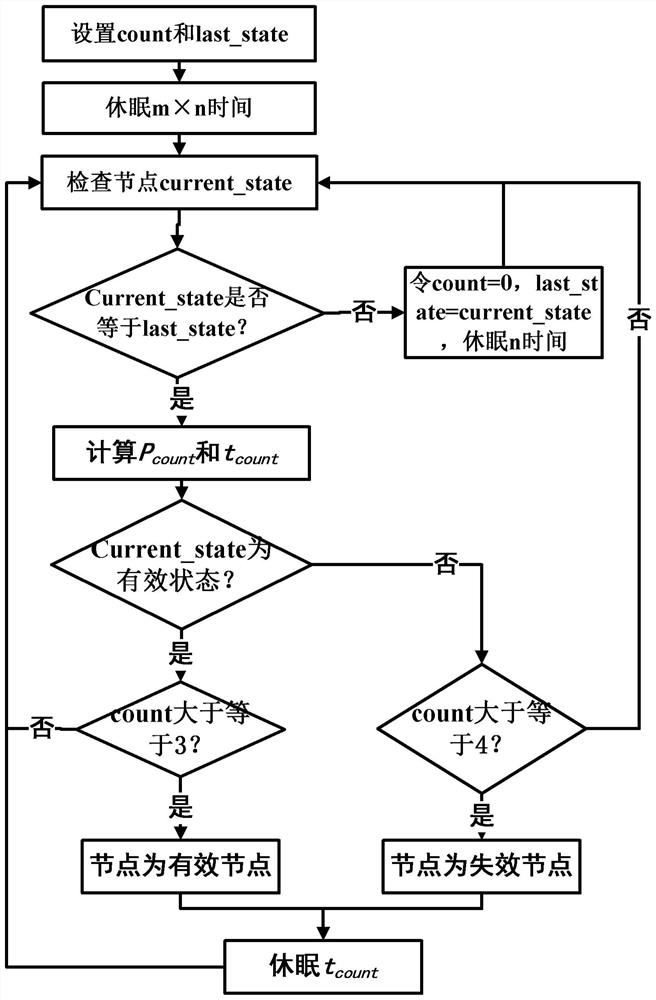

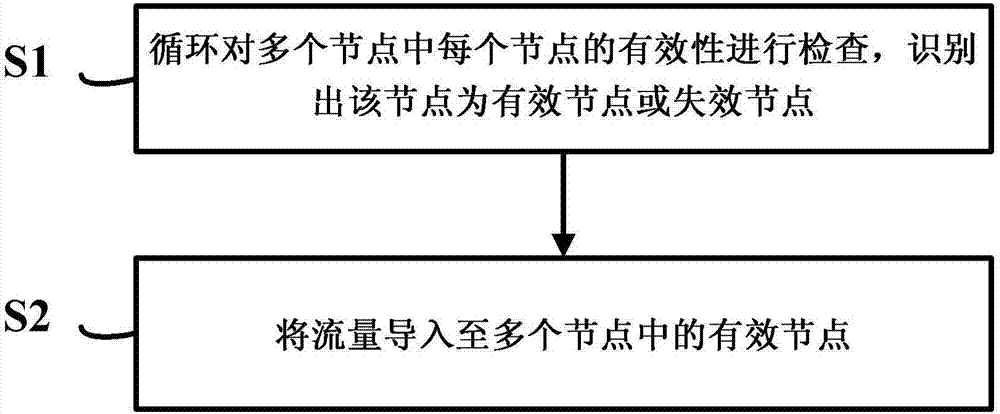

Load balancing method and system

ActiveCN107453938AReduce resource consumptionIncrease the frequency of inspectionsData switching networksResource consumptionReal-time computing

The invention provides a load balancing method and system. After checking the validity of a node each time, the probability that the state of the node is unchanged is calculated when the node is checked next time, and according to the probability, the time interval between this time node checking and next-time node checking is calculated, so that the time interval of node checking can be dynamically changed, therefore, for the nodes with unchanged validity status, the adaptability reduces the checking frequency and reduces the resource consumption required for checking; and for the nodes with changed validity, the adaptability improves the checking frequency and ensures the real-time performance of checking.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Method for monitoring and judging working states of ring spinning frame

ActiveCN103498225BIncrease the frequency of inspectionsCharacteristic curve stabilityTextiles and paperYarnSpinning

The invention discloses a method for monitoring the working state of a ring spinning frame, which is characterized in that: an induction device is installed in the sensing area of the spinning frame balloon, and the induction device senses the digital signal generated by the rotation of the spinning balloon, and outputs The digital signal is analyzed to judge the working status of the ring spinning machine. The method of judging the working state of the ring spinning frame is calibrated by monitoring the output digital signal amplitude and the distance between the actual sensing device and the yarn balloon, and according to the frequency and amplitude maximum and minimum values of the digital signal within a certain period of time , The average value is compared with the set value to analyze the working state of the spinning frame. The invention has the advantages of simple structure, high inspection frequency and stable signal characteristic curve; it can count and calculate the size of the balloon and the rotating speed of the balloon; it can comprehensively diagnose the working state of the spinning frame and perform alarms for various faults.

Owner:苏州盛泽科技创业园发展有限公司

A method for identifying friction-type high-strength bolts falling off in bar connection nodes

InactiveCN107588809BIncrease the frequency of inspectionsAccurate identificationMeasurement devicesEngineeringStrain sensor

The invention discloses a method for recognizing looseness of a friction type high-strength bolt in rod piece connection nodes, which comprises the steps of 10) arranging measuring points on a rod piece connection node splicing plate, and setting a temperature sensor and a fiber grating strain sensor at each measuring point; 20) building the linear change rate of the axial strain of the position of each measuring point along with the temperature field; 30) establishing a distribution curve of the linear change rate along the cross section of each rod piece; 40) performing integration on each of the established distribution curves to obtain corresponding integral values; 50) calculating a first-order difference absolute value of the adjacent integral values, and enabling the distribution curve along the rod axis direction to serve as a fundamental curve; 60) returning back to the step 20) to obtain a real-time curve of the first-order difference absolute value along the rod axis direction at the rth day; and 70) performing looseness recognition on the bolt by using the difference between the real-time curve and the fundamental curve. The looseness position of the high-strength boltcan be accurately recognized according to the recognition method disclosed by the invention.

Owner:CHINA UNIV OF MINING & TECH

Method and program for selecting product to be inspected

InactiveUS20080269936A1Reduce in quantityIncrease the frequency of inspectionsProgramme controlTotal factory controlProduct selectionIndustrial engineering

An inspection-required product selection method and program for minimizing the number of investigation steps at the time of occurrence of a defect of a product placed on the market are disclosed. A combination of product lots to be inspected is assumed based on the information on the material lots used for a product lot scheduled for production for a predetermined future period and the number of the product lots inspected during the same period. The number of the material lots not included in the product lots to be inspected is totalized for each product lot, and the statistical values are calculated for all the conceivable combinations of the product lots. The combination of the product lots optimizing the statistical values is selected for inspection.

Owner:HITACHI LTD

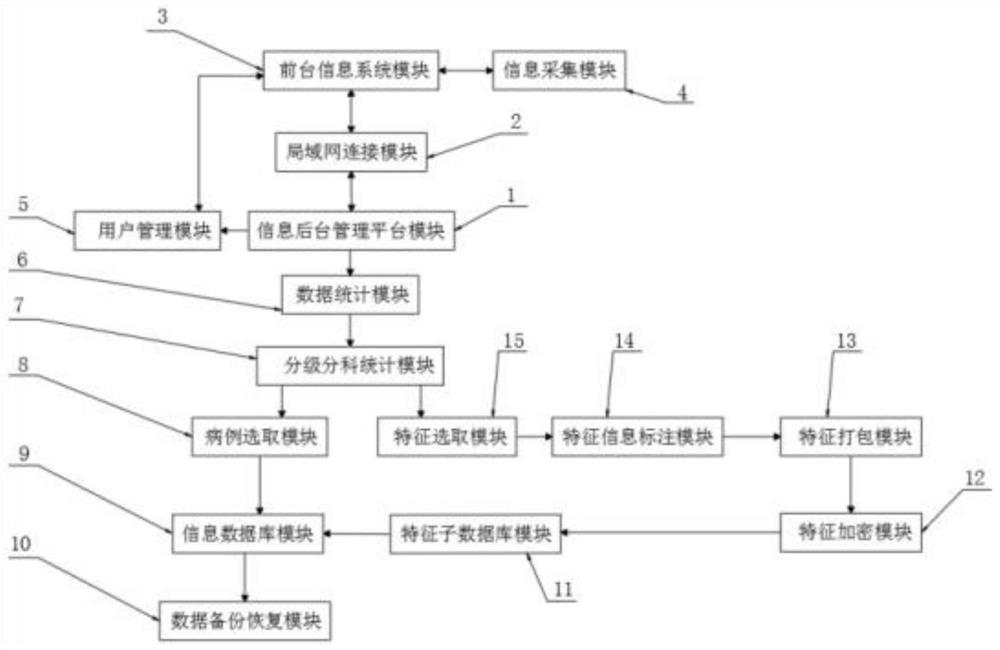

Intelligent monitoring system for socket box

PendingCN114780287ANot affected by working statusExtended time periodDigital data information retrievalDigital data protectionInformation repositoryData information

The invention relates to an intelligent monitoring system for a socket box. Comprising an information background management platform, a local area network connection module, a foreground information system module, an information acquisition module, a user management module, a data statistics module, a classification and division statistics module, a pathology selection module, a data information base module, a data backup recovery module, a feature sub-database module, a feature encryption module and a feature packaging module. A feature information labeling module; and a feature selection module. The intelligent monitoring system achieves the following effects: faults can be found more timely, and problems occurring on the same day can be found when data is transmitted back; inspection operation of workers at night is not depended on any more, and the influence of poor light is avoided. The time period for monitoring the working state of the socket box is expanded, and the inspection frequency is higher; operation and maintenance cost is reduced, and utilization of manpower and material resources is reduced; and the inspection result is more objective and is not influenced by the working state of workers.

Owner:天津博优智能科技有限公司

An automatic inspection system for airport aerial display terminals

ActiveCN109886431BFind faults in timeRealize automatic inspectionDigital data information retrievalRegistering/indicating working of vehiclesAviationEngineering

Owner:BEIJING CAPITAL INT AIRPORT CO LTD

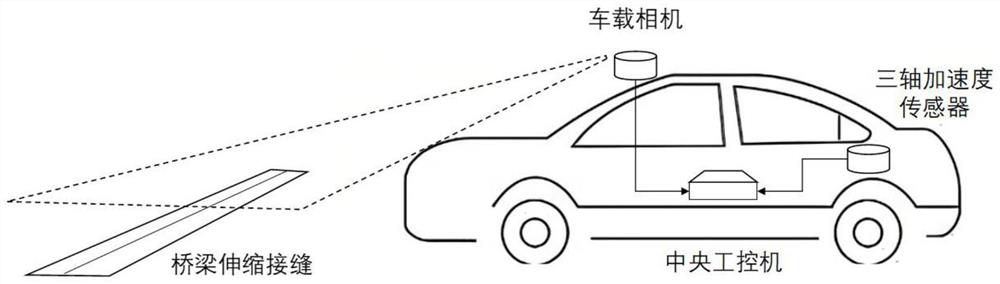

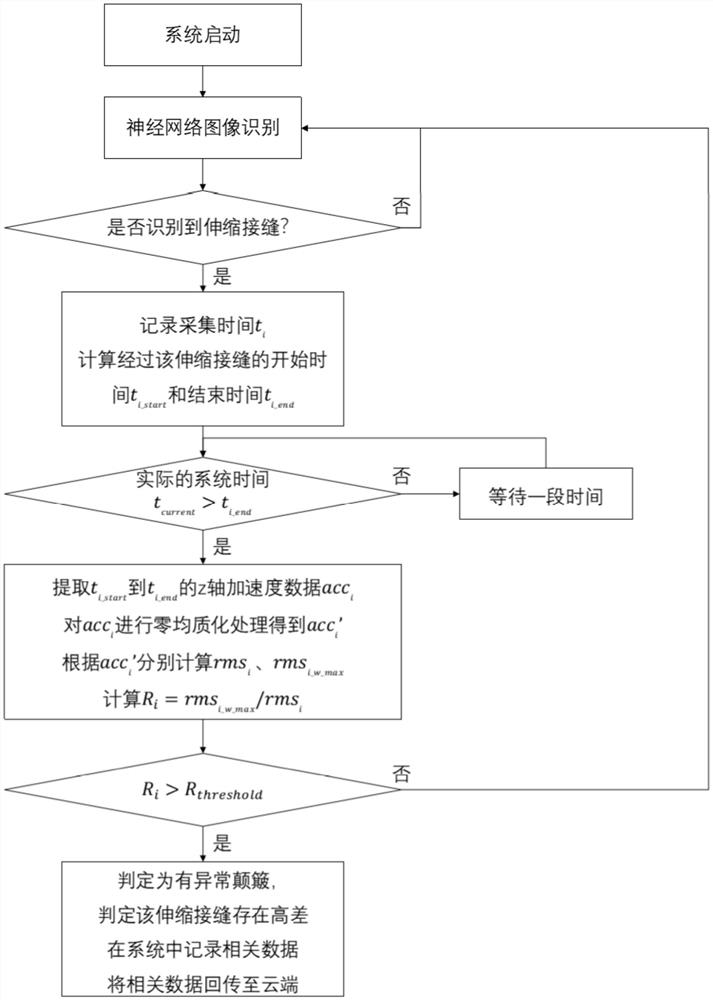

Bridge joint height difference identification method and system based on image and vibration data analysis

PendingCN114266766ATimely detection of height difference problemsAvoid security risksImage analysisNeural architecturesStructural engineeringHeight difference

The invention discloses a bridge joint height difference identification method and system based on image and vibration data analysis, and compared with an existing daily patrol and hiking detection method, the bridge joint height difference identification method and system are more objective in height difference evaluation of telescopic joints, can quickly perform height difference evaluation on the telescopic joints in daily patrol, can timely discover the height difference problem of the telescopic joints, and improve the detection efficiency of the telescopic joints. A maintenance unit is helped to find out possibly damaged telescopic joints early nowadays; by means of high-frequency patrol and high-precision positioning, long-term tracking can be carried out on height difference estimation of the telescopic joint, whether the height difference occurs again or not and whether damage is caused again or not after the telescopic joint is maintained is evaluated, and maintenance personnel can conveniently evaluate whether joint maintenance measures are reasonable or not; besides, the system provided by the invention does not need to be specially operated by personnel, and the inspector only needs to concentrate on driving, so that the safety risk of the inspector is avoided compared with manual hiking inspection.

Owner:SHANGHAI TONGLU CLOUD TRANSPORTATION TECH CO LTD

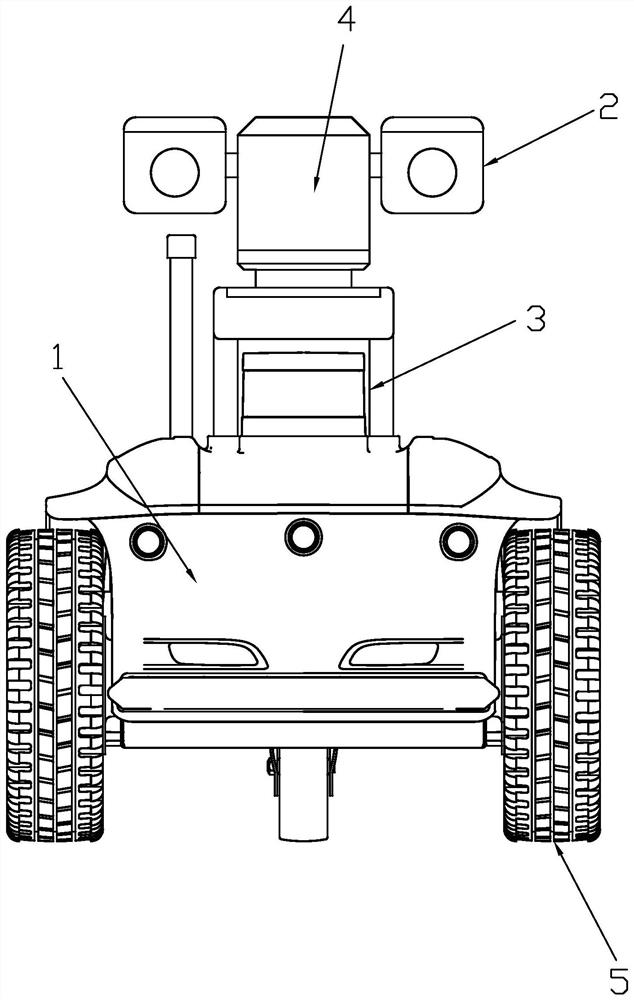

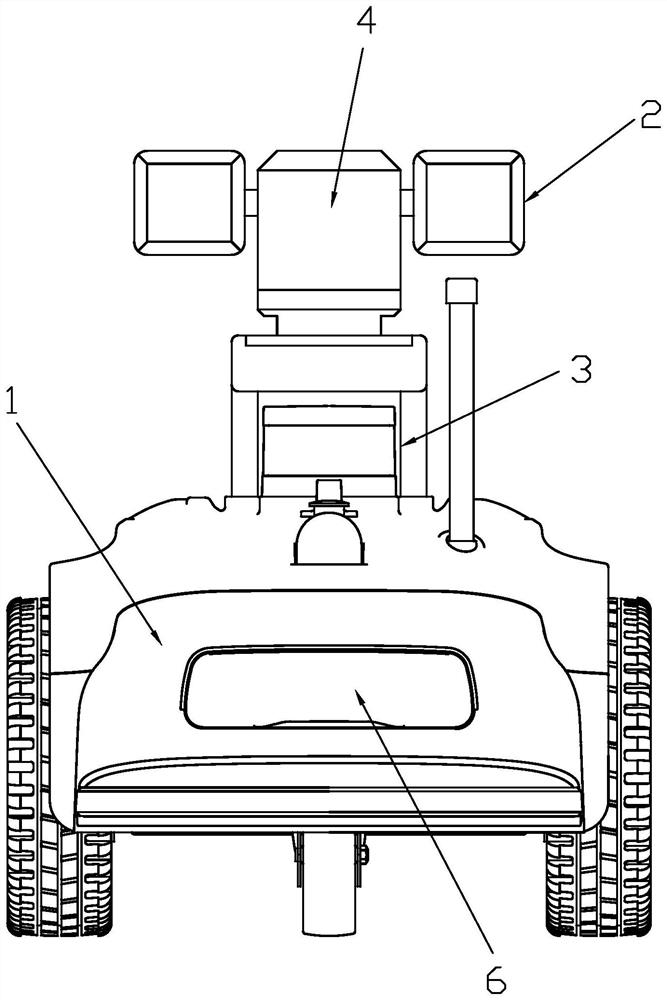

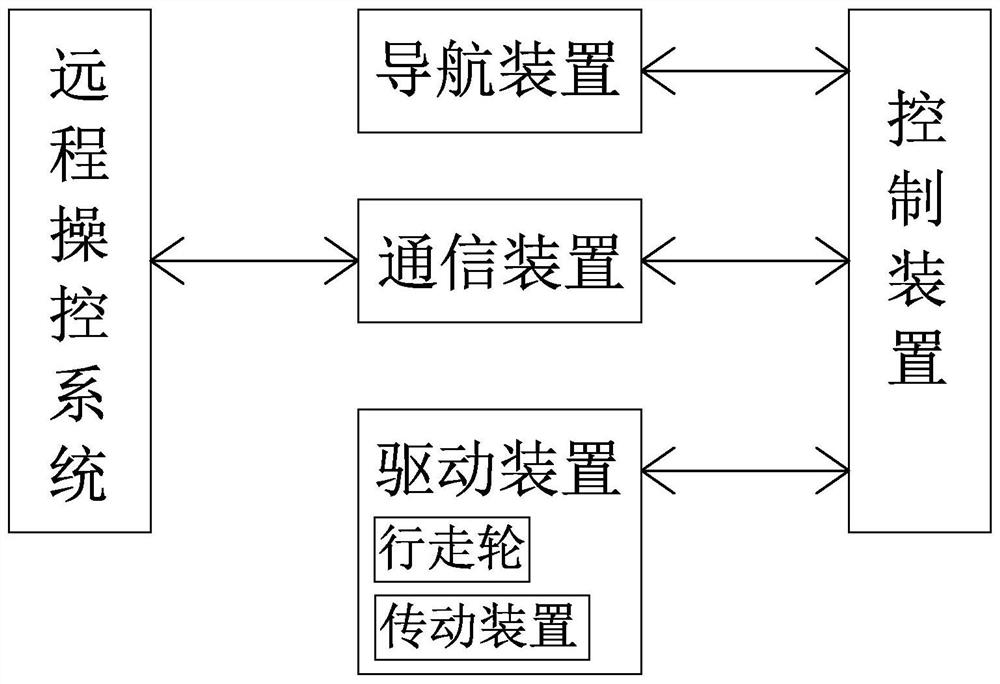

An intelligent inspection robot

ActiveCN109460033BImprove immediacyImprove reliabilityPosition/course control in two dimensionsRotary stageRemote control

The invention discloses an intelligent inspection robot, which comprises a mobile base, a lifting mechanism, a rotating platform and a viewing platform; the lower end of the lifting mechanism is connected and fixed to the moving base, and a rotating platform, the rotating platform is rotatably installed on the upper end of the lifting mechanism with the center line of the lifting mechanism as the axis, and the inspection platform is articulated on the rotating platform; the mobile base includes a navigation device, a communication device , a driving device and a control device, the navigation device, the communication device, and the driving device are respectively connected to the control device; the communication device is connected to a remote control system. With this intelligent inspection robot, the position and angle of the inspection platform can be flexibly adjusted according to needs, and has good applicability. Using this inspection robot to replace manual inspections on substations increases inspection frequency and improves the immediacy and reliability of inspection results. sex.

Owner:HANGZHOU SHENHAO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com