Intelligent inspection device for belt conveyor in complex industrial environment

An industrial environment, intelligent inspection technology, applied in conveyor control devices, measuring devices, manipulators, etc., to reduce workload and safety risks, improve inspection frequency and inspection quality, improve operation and maintenance efficiency and production management level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below in conjunction with embodiment.

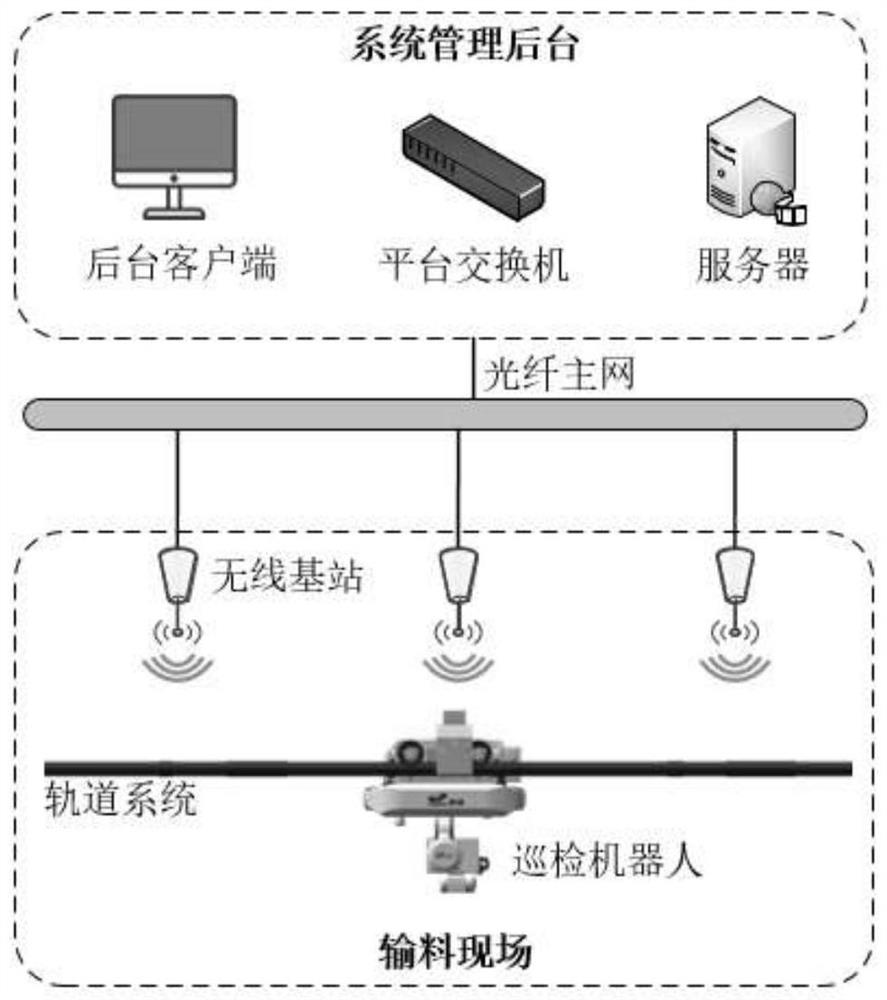

[0029] The invention takes the inspection robot as the core, and is equipped with a track system, a power supply system, a communication system, and a background management system. System architecture such as figure 1 As shown; the inspection robot is equipped with information collection equipment such as a visible light camera, an infrared thermal imager, and a pickup. Information such as the content of harmful gases in the medium, alarms and other data are transmitted back to the system background through the communication system, where they are classified, stored, analyzed, and displayed, so as to realize the full-coverage closed-loop inspection of the ironmaking blast furnace conveying system of the iron and steel plant. Provide strong support for maintenance personnel to control the equipment status of the conveying system.

[0030] Inspection robot: The inspection robot is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com