Non destructive rectangle groove dimension detecting method

A dimensional detection, non-destructive technology, applied in the field of detection, can solve the problems of not being able to guarantee the quality very well, difficult to measure the size of the rectangular slot, long cycle, etc., to increase the inspection frequency, reduce the inspection cycle and improve the efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

[0014] This non-destructive rectangular groove size detection method of the present invention comprises the following steps:

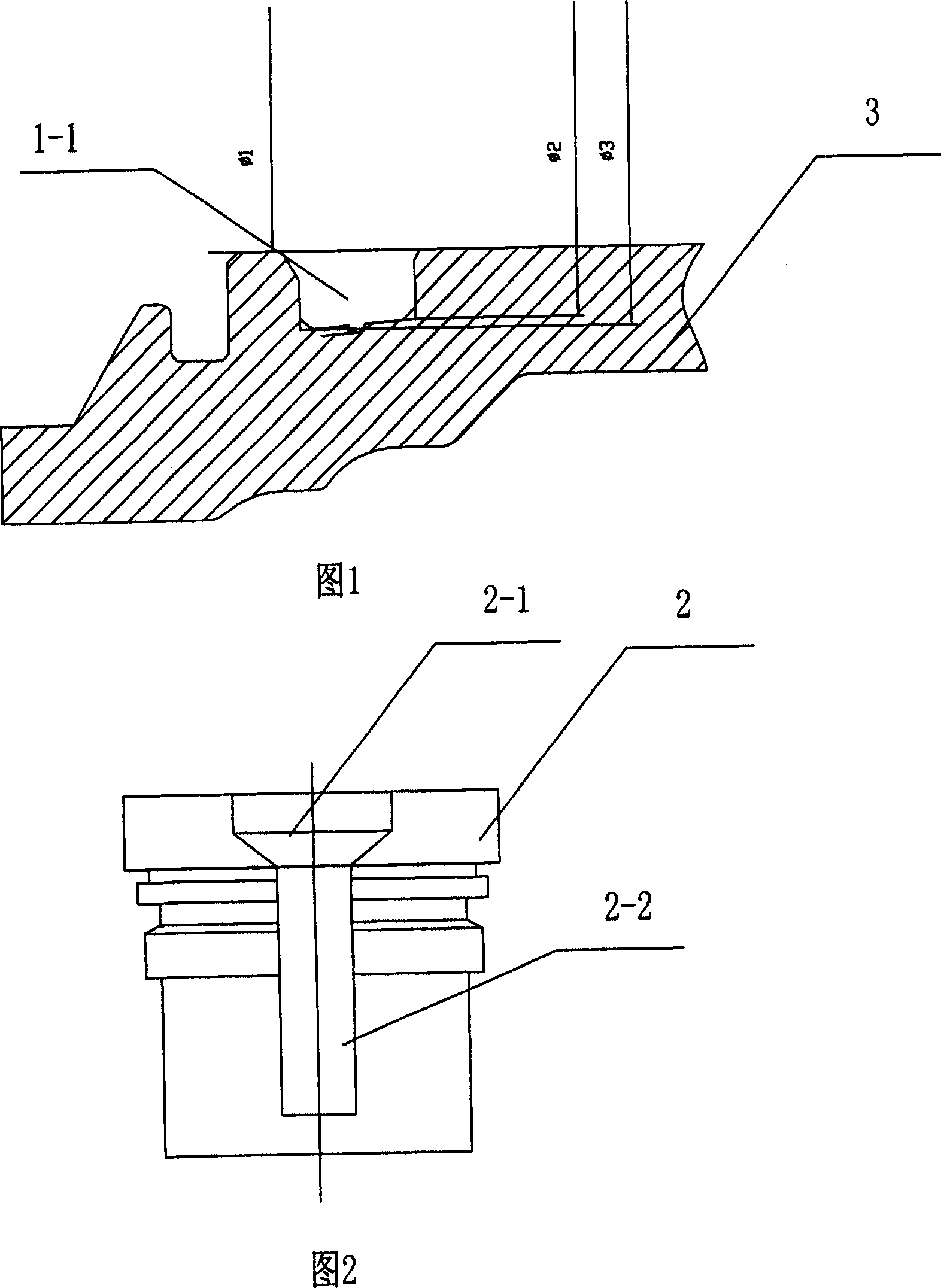

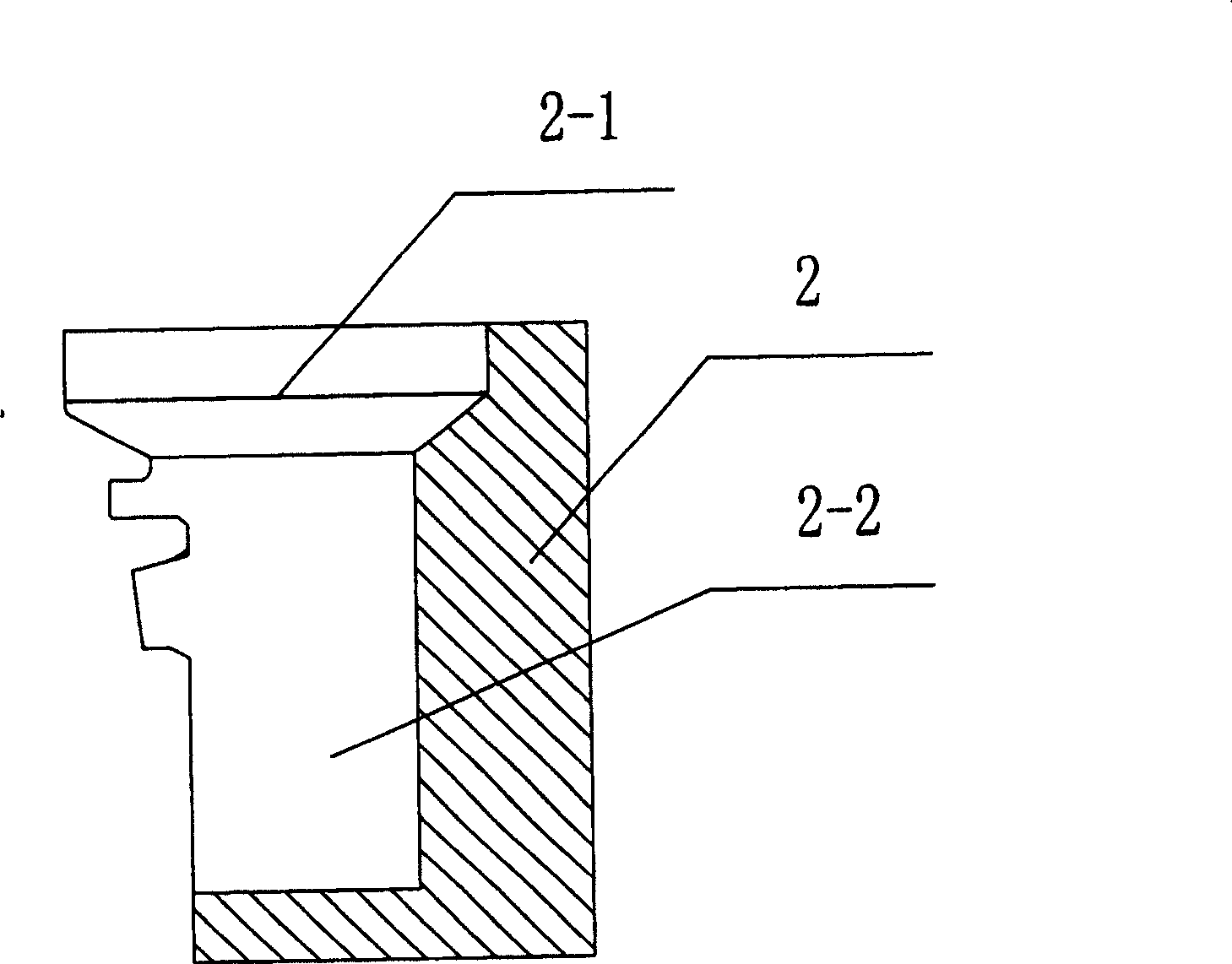

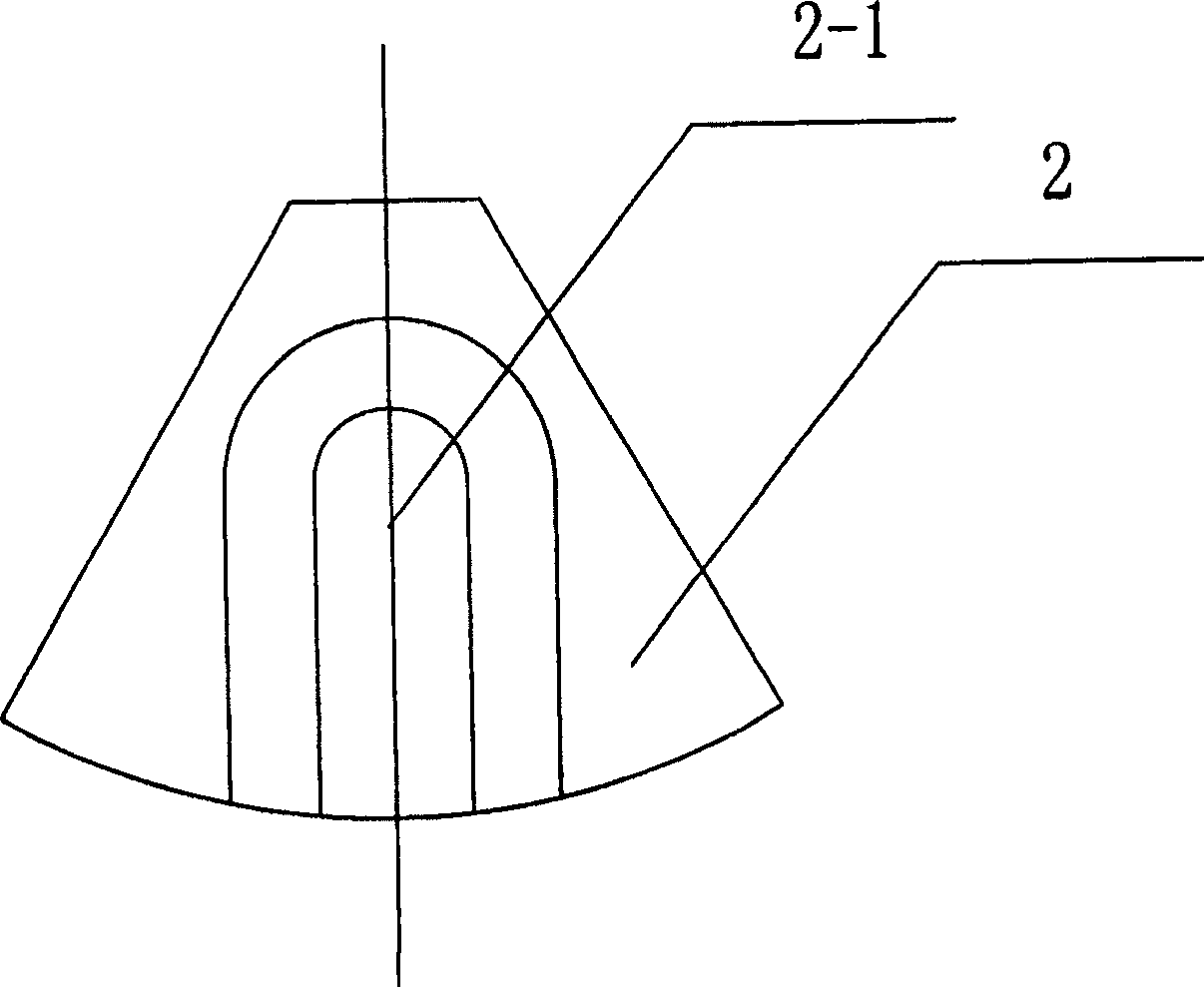

[0015] 1) Make a casting mold 2 (as shown in Figure 2-4) according to the shape of a section of the inner cavity wall on the caliper 1, and the selected section of the inner cavity wall includes a rectangular groove 1-1; the outer surface shape of the casting mold 2 It is concave-convex fit with the shape of the inner cavity wall (mainly used to block the fusible metal and prevent outflow), the pouring mold 2 includes the pouring port 2-1 and the pouring cavity 2-2 which are connected to each other, and the pouring cavity 2- 2 and the pouring port 2-1 are cavities with side openings, and the openings of the cavities are located on the outer surface of the casting mold 2 matched with the inner cavity wall;

[0016] 2) Put the pouring mold 2 against ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com