Automatic diagnosis system and method for rotating mechanical equipment

A rotating machinery equipment, automatic diagnosis technology, applied in the testing of mechanical parts, the testing of machine/structural parts, instruments, etc., can solve the problems of measurement object and result accuracy limitation, increase equipment cost, etc., to improve the inspection frequency , easy to operate, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

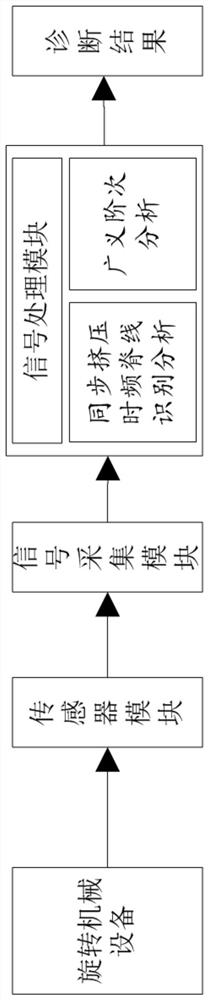

[0026] see figure 1 , an automatic diagnosis system for rotating machinery equipment, comprising a sensor module, a signal acquisition module and a signal processing module, wherein the sensor module, the signal acquisition module and the signal processing module are connected in sequence;

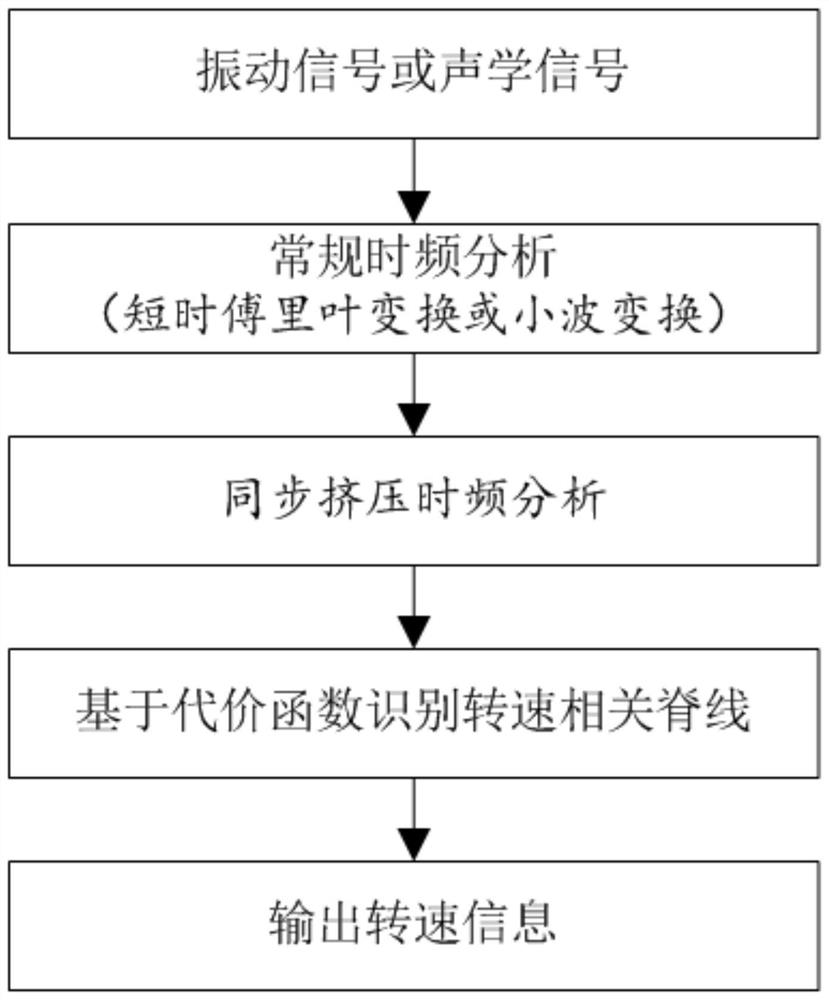

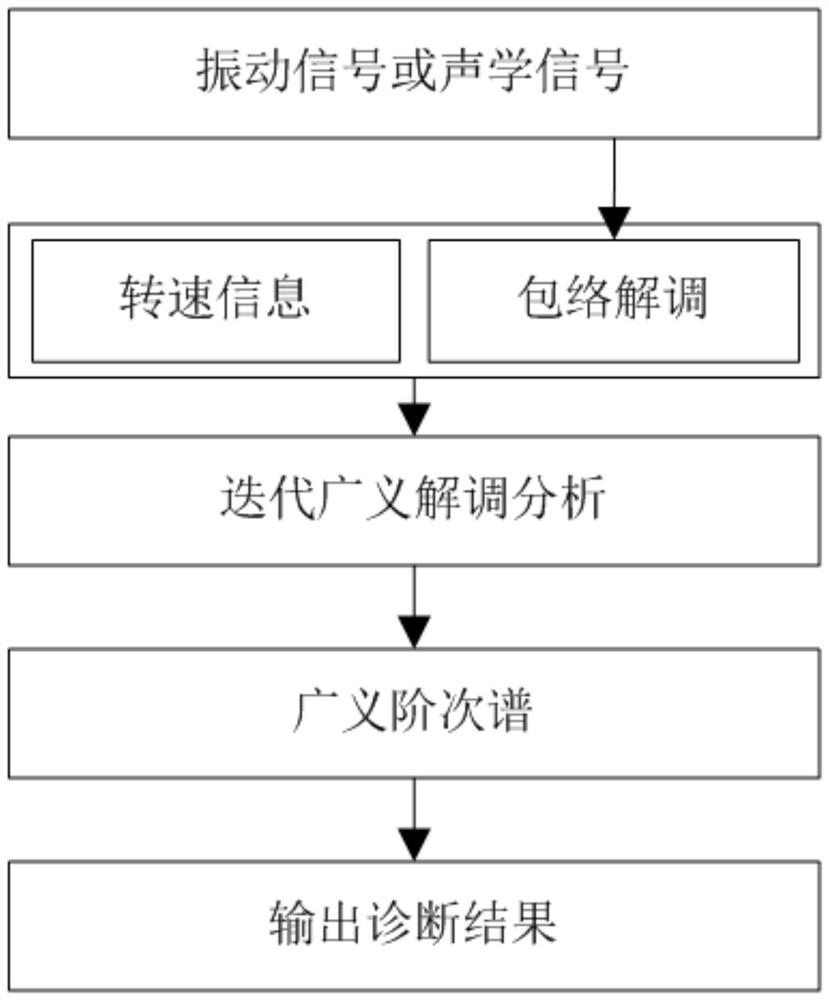

[0027] a sensor module for obtaining vibration or acoustic signals, the input end of the sensor module is connected to the rotating mechanical equipment, and the output end is connected to the signal acquisition module, the sensor module includes at least one vibration acceleration sensor or at least one acoustic sensor;

[0028] The vibration sensor is fixed on the monitoring point of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com