Method for monitoring and judging working states of ring spinning frame

A working state, spinning frame technology, applied in textiles and papermaking, etc., can solve the problems of requiring air source, high investment cost, difficult sensitive, stable and reliable operation of the system, etc., to achieve the effect of stable characteristic curve and high inspection frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

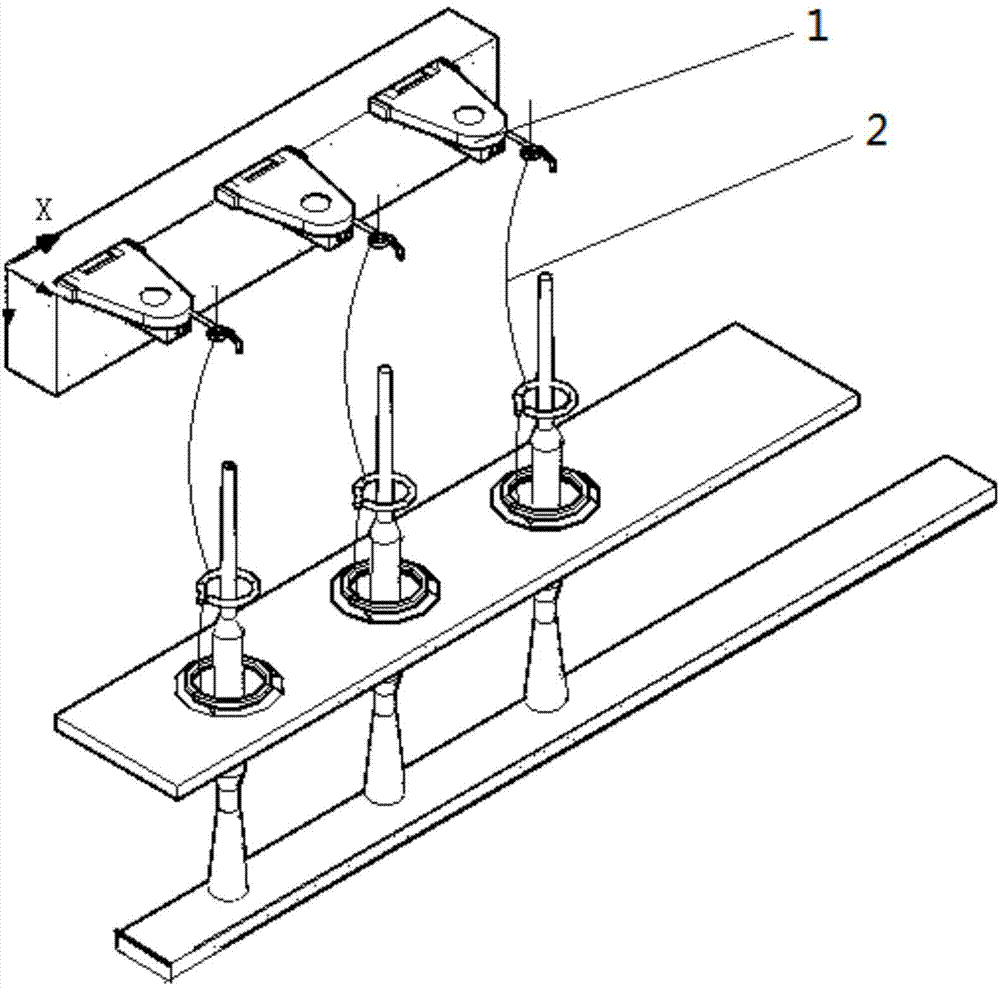

[0043] Such as image 3 In a preferred embodiment shown, the photodetection device 1 composed of a luminescent tube and a photoelectric receiver is installed on the yarn guide hook. The light-emitting tube corresponding to each bobbin coil and the probe of the photoelectric receiving device are installed on the balloon yarn path 2 of the spinning frame. The intersection point of the emitting central axis of the probe luminous tube and the receiving central axis of the photoelectric receiving device is located above the yarn balloon in the yarn path, so the yarn balloon serves as a reflecting surface. When the luminescent tube and the photoelectric receiving device work, the yarn When the air circle passes through the intersection of the light-emitting tube and the photoelectric receiving device, the light received by the photoelectric receiving device passes through such as Figure 4 The circuit shown is for signal processing. The formed balloon signal of the yarn is passed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com